Category: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

Sustainable Concrete Pavement Incorporating RAP and Fly Ash with Self-Sensing Properties

Pavimento de hormigón sostenible que incorpora RAP y cenizas volantes con propiedades de autodetección

Mohammed Refat1 *, Ali M. Al-Dahawi1 *, Husam Hikmat Baqir1 *

1University of Technology-Iraq, Civil Engineering Department. Iraq.

Cite as: Refat M, Al-Dahawi AM, Baqir HH. Sustainable concrete pavement incorporating RAP and fly ash with self-sensing properties. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:870. https://doi.org/10.56294/sctconf2024870

Submitted: 06-02-2024 Revised: 21-04-2024 Accepted: 10-06-2024 Published: 11-06-2024

Editor:

Dr.

William Castillo-González ![]()

Note: paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

This research focuses on addressing the problem of utilizing high-value sustainable materials in the creation of self-sensing concrete pavement. The study specifically explores the incorporation of reclaimed asphalt pavement (RAP), fly ash, and silica fume in a single mix design to achieve sustainability objectives. In the previous work by the authors, laboratory experiments were conducted to determine the optimal proportions of RAP, fly ash, and silica fume, with a focus on achieving desired mechanical properties. Mechanical tests, encompassing compressive strength, flexural strength, and indirect tensile strength, were conducted within this framework to assess the performance of the concrete mixture. The selected concrete mix in this study incorporated 40 % RAP as a replacement for virgin aggregate, a fly ash-to-cement ratio of 0,8, and the addition of silica fume at 8 % relative to the weight of cementitious materials. Structural health and durability were monitored in real time by embedding two electrodes within the concrete matrix. The results highlighted the significant impact of adding RAP, fly ash, and silica fume on the mechanical properties of the hardened concrete. The optimized combination design indicated improved strength and self-sensing behavior, which was related to the beneficial impacts of silica fume and fly ash on mechanical and self-sensing capabilities. This research contributes to the advancement of sustainable and intelligent infrastructure by demonstrating the feasibility of integrating recycled materials and self-sensing technology into concrete pavement construction. Additionally, the study extended its investigation to evaluate the performance of sustainable concrete under dynamic loads using ANSYS analysis. The investigation, which was performed on a structure with dimensions of 21 meters in length and 3 meters in width, observed that the use of sustainable materials improved the mechanical behavior of the structure under moving loads.

Keywords: Self-Sensing; Fly Ash; Recycled Asphalt Pavement; Waste Material; Silica Fume; Mechanical Properties.

RESUMEN

Esta investigación se centra en abordar el problema de la utilización de materiales sostenibles de alto valor en la creación de pavimento de hormigón autodetectable. El estudio explora específicamente la incorporación de pavimento de asfalto recuperado (RAP), cenizas volantes y humo de sílice en un único diseño de mezcla para alcanzar los objetivos de sostenibilidad. En el trabajo previo de los autores, se llevaron a cabo experimentos de laboratorio para determinar las proporciones óptimas de RAP, cenizas volantes y humo de sílice, centrándose en la consecución de las propiedades mecánicas deseadas. En este marco se realizaron ensayos mecánicos, que incluían resistencia a la compresión, resistencia a la flexión y resistencia a la tracción indirecta, para evaluar el comportamiento de la mezcla de hormigón. La mezcla de hormigón seleccionada en este estudio incorporaba un 40 % de RAP en sustitución del árido virgen, una relación cenizas volantes-cemento de 0,8 y la adición de humo de sílice en un 8 % en relación con el peso de los materiales cementantes. La salud estructural y la durabilidad se controlaron en tiempo real incrustando dos electrodos en la matriz de hormigón. Los resultados pusieron de manifiesto el impacto significativo de la adición de RAP, cenizas volantes y humo de sílice en las propiedades mecánicas del hormigón endurecido. El diseño optimizado de la combinación indicó una mejora de la resistencia y del comportamiento de autodetección, lo que se relacionó con los efectos beneficiosos del humo de sílice y las cenizas volantes sobre las capacidades mecánicas y de autodetección. Esta investigación contribuye al avance de las infraestructuras sostenibles e inteligentes al demostrar la viabilidad de integrar materiales reciclados y tecnología de autodetección en la construcción de pavimentos de hormigón. Además, el estudio amplió su investigación para evaluar el comportamiento del hormigón sostenible bajo cargas dinámicas utilizando el análisis ANSYS. La investigación, que se realizó sobre una estructura con unas dimensiones de 21 metros de longitud y 3 metros de anchura, observó que el uso de materiales sostenibles mejoraba el comportamiento mecánico de la estructura bajo cargas en movimiento.

Palabras clave: Autodetección; Cenizas Volantes; Pavimento Asfáltico Reciclado; Material de Desecho; Humo de Sílice; Propiedades Mecánicas.

INTRODUCTION

Concrete, as an essential building material, has been an essential element in the construction industry for numerous generations.(1) There has been a huge increase in the desire for concrete to exhibit properties beyond its conventional duty as a fundamental structural constituent. The emergence of self-sensing concrete marks a revolutionary advancement in construction materials, as it can autonomously monitor its structural well-being and offer instantaneous data on its state.(2,3,4)

A comprehensive literature review is adopted in this introduction to cover related works, Hanjitsuwan et al.(5) conducted measurements on the electrical conductivity of various geopolymer pastes, varying the alkaline-to-fly ash (L/A) ratios. The recorded electrical conductivity values for geopolymers were approximately 10−3 S m−1 and 5 × 10−4 S m−1 at L/A ratios of 0,4 and 0,7, respectively. Mohamed Saafi(6) states that the electrical and piezoresistive characteristics of geopolymers derived from fly ash, incorporating in situ reduced graphene oxide (GO) sheets, were examined and documented in this report. Fourier-transform infrared (FTIR) analysis revealed that the original GO undergoes a reduction in the course of geopolymers’ processing. Cecílie Mizerová et al.(7) show that the examination of compressive strain and acoustic emission data revealed that fly ash geopolymer lacks the necessary rigidity. Under loading conditions, it experiences permanent deformations, attributed in part to the creation of micro defects in the binder’s structure and partly to the transition from quasi-brittle to more ductile properties with the introduction of carbon black. This transformation is evident in the elevated electrical resistance observed in the unloaded material. Wenkui Dong et al.(8) refer that the piezoresistivity of CB-cementitious composites experienced substantial enhancement upon the incorporation of SF, particularly at a 10 % SF content. The FCR values underwent rapid changes during the initial loading phase, followed by a gradual deceleration with the escalating compressive stress. Significantly, samples with 5 % and 10 % SF had higher piezoresistivity under prolonged stress when compared to specimens with a 20 % SF concentration.

The primary research gap is efficiently integrating high-value sustainable materials into the building of self-sensing concrete pavements. A significant focus in the field of self-sensing concrete investigation has been on introducing sustainable components into the concrete mixture to improve its structural and sensing qualities. This study focuses on the use of silica fume as well as recycled aggregate pavement (RAP) with other materials, with a particular emphasis on their self-sensing capabilities. Silica fume emerges as a pivotal focus within the ambit of this investigation due to its distinctive chemical composition, encompassing hydrated sodium (Na) and potassium (K) ions. This unique constitution renders silica fume an intriguing candidate for augmenting the self-sensing attributes of concrete.(9) Silica fume extracted from thermal power plant emissions by a combination of mechanical and electrostatic filtration methods. It is produced by a number of industrial processes, the most prevalent of which being pulverized coal combustion. This environmentally conscientious extraction method is aligned with the overall sustainability aims of the research project.(10)

Fly ash, plays an important function as a material incorporated into the concrete amalgamation. It is a byproduct of pulverized coal combustion.(11) and type F fly ash, being prevalently encountered, stands out as one of the most common varieties. Its inclusion in the blend not only enhances the sustainability of the research but also significantly contributes to conferring self-sensing capabilities upon the concrete.(12,13). Type F fly ash encompasses diverse chemical elements capable of influencing the electrical properties of concrete,(7) thereby establishing its indispensability in the development of self-sensing abilities. The incorporation of Reclaimed Asphalt Pavement (RAP) represents an enhanced environmentally sustainable element within this study, sourced from the reclamation process of disassembled concrete structures.(14,15) The utilization of Recycled Asphalt Paving (RAP) in concrete mixes has not only reduced the demand for virgin aggregates but has also minimized construction waste. This paper advocates for the adoption of a circular economy approach in conjunction with enhancements in the autonomous structural monitoring of concrete. Self-sensing concrete denotes the intrinsic ability of a material to identify and communicate changes in structural integrity and condition without relying on external sensors or monitoring systems. Through the incorporation of silica fume, type F fly ash, and recycled asphalt pavement (RAP), various electrical characteristics are integrated into the concrete amalgamation, enabling the material to autonomously identify tension, strain, and potential structural abnormalities. This autonomous self-sensing feature is pivotal in both architectural and infrastructural sectors, providing real-time data on the state and condition of the system.(16)

In this study, smart sustainable concrete was created and tested for mechanical properties and self-sensing abilities utilizing fly ash type F and silica fume. The electrical resistivity was determined using the two-probe method with the aid of a direct current (DC) source meter. All test results for mechanical and self-sensing characteristics were evaluated and exhibited in this research to reduce the damage to nature and for financial reasons by counting on nondestructive tests and sustainable material, which could result in enhanced structural performance, reduced environmental impact, and improved maintenance practices. This research endeavors to address the challenge of optimizing the utilization of a substantial volume of sustainable materials, namely silica fume, type F fly ash, and recycled asphalt pavement (RAP), with the aim of attaining improved mechanical properties and fostering self-sensing behavior in the construction of concrete pavements. The objective is to advance sustainable and intelligent infrastructure by highlighting the possibilities of incorporating recycled materials and self-sensing technology in concrete pavement construction. integration of 40 % Recycled Asphalt Pavement (RAP) in lieu of virgin aggregate, maintaining a fly ash-to-cement ratio of 0,8, and introducing silica fume at a rate of 8 % relative to the weight of cementitious materials. Real-time structural health and durability monitoring is achieved through strategically embedded electrodes within the concrete matrix.

LABORATORY EXPERIMENTS

Materials

In the context of this framework. Concrete containing recycled asphalt pavement (RAP) and fly ash was used. Rap concentration was 40 % from the virgin aggregate, and the fly ash to cement ratio was 0,8.

Cement

Sulfate Resisting Portland Cement, specifically identified as Type V CEM I 42,5 SR in accordance with the Iraqi Standard No. 5/1984(17) was employed in this study. The selection of this particular variant of cement predominantly finds its application within the realm of civil engineering, notably in the construction of vital components such as concrete foundations, structural elements, and infrastructural features, exemplified by rigid pavements, which are in direct juxtaposition with soil compositions containing sulfates. The procurement of the Portland cement employed herein was conducted at the Karbala Cement Factory, situated within the esteemed Karbala Governorate. The molecular and physical characteristics of this cement adhere to the specifications outlined in ASTM C150.(18) Comprehensive details concerning the chemical attributes of Portland cement are delineated in table 1.

|

Table 1. Chemical characteristics of the Portland cement used |

|||

|

Chemical specifications |

Test method |

Specification |

Test result |

|

Loss on ignition |

IQS472/1993 |

<4,1 |

3,57 |

|

Non-Soluble Materials |

≤1,4 |

0,51 |

|

|

Sulphate Level |

2,5 if C3A≤ 3,6 |

2,38

|

|

|

2,5 if C3A ≥ 3,5 |

|||

|

Tricalcium Aluminates |

≤ 3,5 |

2,5 |

|

|

Magnesium Oxide |

≤ 5,0 |

1,76 |

|

|

Chloride Level |

BS EN196-2/2013 |

≤ 0,1 |

0,04 |

Table 2 illustrates the requisite physical and mechanical attributes of Portland cement as stipulated by standard specifications.

|

Table 2. Physical and mechanical properties of the Portland cement used |

||||

|

Physical and mechanical requirements |

Standards |

Limitation |

Test result |

|

|

Finesse (Blaine) |

m2/kg |

IQS198/1990 |

≥ 300 |

343 |

|

Initial curing Times |

minutes |

BS EN196-3/2016 |

≥ 45 |

152 |

|

Final curing Times |

minutes |

≤ 10 |

3,17 |

|

|

Soundness (expansion)-Le Chatle |

mm |

≤ 10 |

0,3 |

|

|

Compressive strength is not below (MPa) |

7 days |

BS EN196-3/2016 |

≥ 20,0 |

23,1 |

|

28 days |

≥ 42,4 |

48,3 |

||

Fine aggregates

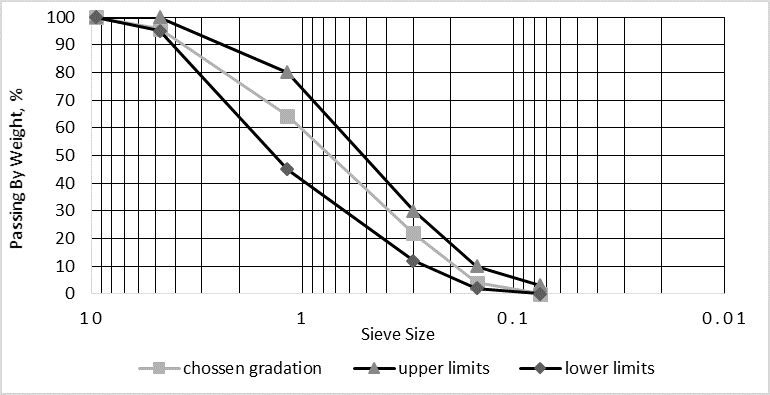

In this research, fine aggregates, which have passed through sieve No. 4, were employed from the Al-Ukhaider region. A sieving shaker was utilized to classify the fine aggregates into different size fractions, facilitating the selection of the optimal gradation. The chosen gradation is presented figuratively in figure 1.

Figure 1. Fine aggregates gradation

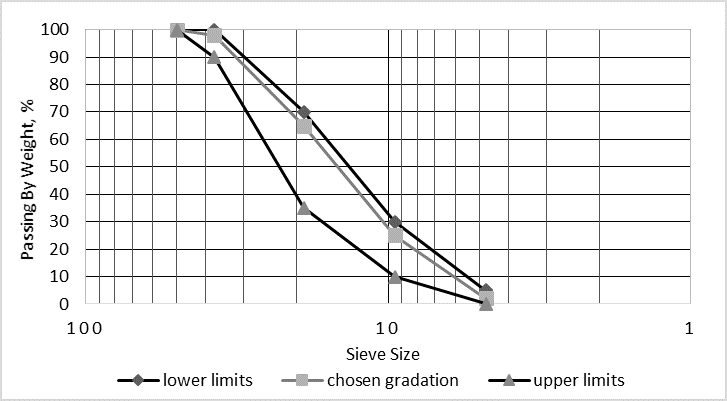

Coarse aggregate

In this paper, crushed gravel sourced from the Al-Nibaai quarry has been utilized. Employing a sieve analysis apparatus, the coarse aggregate has been sorted into different size fractions to align with the optimal gradation, as detailed visually represented in figure 2. Subsequently, the aggregate has been thoroughly cleansed using water and subsequently subjected to air drying.

Fly ash

Fly ash, also recognized as pulverized fuel ash, has been precipitated electrostatically or mechanically from the exhaust emissions of coal-fired power plants. It stands as the most prevalent artificial pozzolana. The fly ash particles have assumed a spherical shape, which offers advantageous characteristics concerning water requirements and they exhibit exceptionally high fineness. The majority of these particles measure less than 1μm to 100μm in diameter, and the specific surface area typically falls within the range of 250 to 600 m2/kg.(19) The chemical composition of fly ash has been scrutinized following the ASTM C618 standard(20) with the respective test outcomes detailed in table 5.

Figure 2. Coarse aggregates gradation

Silica fume

Silica fume is also commonly referred to as micro silica. This material emerges as a secondary byproduct of silicon and ferrosilicon alloy production, achieved by employing high-purity quartz and coal in a submerged-arc electric furnace. During this process, gaseous SiO undergoes oxidation and condenses into minute spherical particles composed of amorphous silica (SiO2), which are colloquially termed silica fumes.(21) The amorphous nature of silica, akin to glass, exhibits a notably high reactivity, and silica fume possesses a specific gravity of 2,4. Furthermore, the minuscule size of these particles accelerates reactions when in contact with calcium hydroxide, a product generated during the hydration of Portland cement. Silica fume granules typically boast an average diameter of approximately 0,1 to 0,5 µm, consisting of more than 85 percent amorphous silicon dioxide, and they exhibit an exceedingly fine spherical morphology.(22) In compliance with the ASTM C1240 Standard.(23) the chemical composition of silica fume underwent meticulous analysis, with the corresponding test results thoughtfully presented in table 4.

|

Table 3. Fly ash chemical components |

||

|

Chemical components |

Test result |

Limitations according to ASTM C618(20) |

|

SiO2 |

47,68 |

- |

|

Al2O3 |

27,74 |

- |

|

Fe2O3 |

18,42 |

- |

|

SiO2+AL2 O3+Fe2O3 |

93,84 |

70 minimum |

|

CaO |

5,12 |

6 maximum |

|

MgO |

2,58 |

3 maximum |

|

Ignition loss |

3,71 |

6 maximum |

|

Table 4. Silica fume chemical components |

||

|

Chemical components |

Test result |

Limitations according to ASTM C1240(23) |

|

SiO2 |

104,9 % |

85 % min. |

|

Moisture content |

2 % |

3 % max. |

|

Loss on ignition |

3,1 % |

6 % max. |

Water and Superplasticizer

Throughout the mixing and curing phases of the samples, potable water has been employed alongside chemical additives, notably a high-range water-reducing admixture (HRWRA). The aim was to reduce the amount of water needed while simultaneously improving the workability of the samples. The specific properties and characteristics of the HRWRA utilized are elucidated in table 5.

|

Table 5. Superplasticizer specification |

|||

|

Appearance |

Turbid liquid density |

Dosage |

Toxicity hazardous |

|

Turbid liquid |

1,094 kg/Lt. |

0,2-0,7 % The weight of cement per Liter. |

The product is deemed non-toxic according to applicable health and safety regulations |

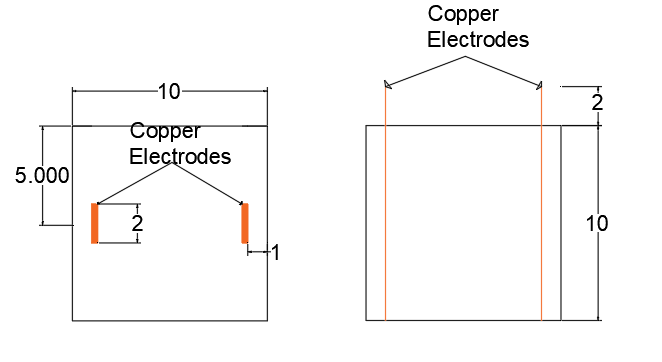

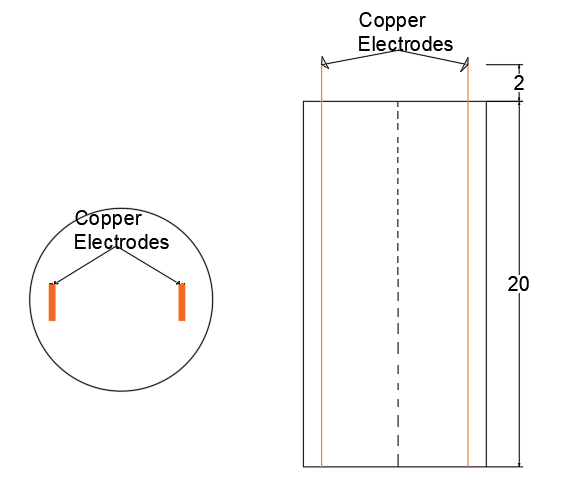

Electrodes

The utilization of brass plate electrodes was dependent upon the specific test being conducted, with varying dimensions as given in table6. This is a metallic amalgam comprising of copper (70 %) as well as zinc (30 %). The fabricated specimens were embedded with electrodes in the fresh concrete to observe their piezoresistive behavior under varying loading conditions. The electrode with distinct geometrical dimensions was chosen following prior research conducted by Al-Dahawi et al.(2).

|

Table 7. Dimensions of electrodes used |

||

|

Type of mechanical test |

Specimen type |

Electrode dimension in (mm) (Length×Width×Thickness) |

|

Uniaxial compression |

Cube |

120×10×1 |

|

Indirect tensile |

Cylinder |

220×10×1 |

|

Bending |

Prism |

120×10×1 |

Fabricating of the mixture

A laboratory experiment has been conducted to investigate the self-sensing properties of Portland cement concrete pavement, incorporating recycled asphalt pavement (RAP) and fly ash as substitutes for virgin materials. The components selected for this work were combined within a laboratory mixer with a maximum capacity of 60 liters. The concrete mixing process comprises two distinct phases: dry mixing and wet mixing. The dry mixing phase involving, also, has two specific steps. In the initial step, a two-minute mixing process is dedicated to blending coarse and fine aggregates of both natural and recycled (RAP) materials. Subsequently, in the second step, Portland cement, fly ash, and silica fume are introduced, followed by an additional one minute of mixing. These combined steps result in a dry mixture, the preparation of which takes a total of three minutes.

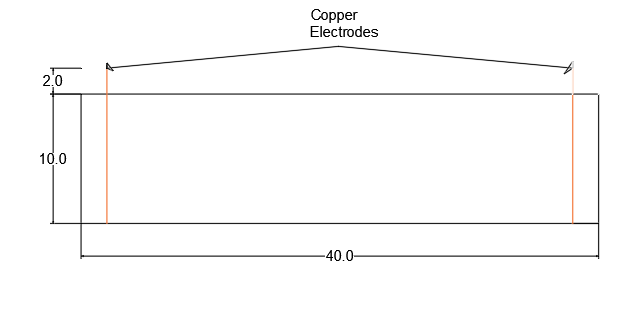

The subsequent procedural step entails the wet mixing process, distinguished by the incremental introduction of water into the amalgam, concomitant with the integration of a superplasticizer to augment workability. The wet mixing procedure persists for a temporal span ranging from three to five minutes, culminating when optimal homogeneity is attained. The rotational velocity during mixing remains consistently fixed at 16 revolutions per minute. The specific weight ratios instituted for this empirical investigation are steadfastly defined as (1,00:2,32:3,26), signifying the respective proportions of Portland cement, sand, and gravel. The selection of these ratios is predicated upon antecedent research findings.(24) The chosen concrete mix in this study used a combination of Reclaimed Asphalt Pavement (RAP) & fly ash. The RAP component accounted for 40 % of the total amount of virgin aggregate, while the fly ash-to-cement ratio remained constant at 0,8.(13) Furthermore, silica fume was added to the blend at a ratio of 8 % as a cementitious material addition by weight. This mix involves embedding two separate brass plates that have a (1 mm) thickness as electrodes within the generated fresh concrete matrix, as illustrated in plate 1.

This particular electrode arrangement was chosen for its capacity to produce high FCER (Fractional Change in Electrical Resistivity) values. According to Al-Dahawi et al.(25) the present work adopted the same electrode arrangement. Specifically, brass plate electrodes were embedded in parallel to one another within the molded mixtures during the fresh state. The insertion of these electrodes was carried out at the midsection of the pouring face of each specimen. The mixtures produced have been poured into molds made of oiled steel and wood. These mixtures were then stored within these molds under conditions of 50±5 % humidity and at a temperature of 25±2°C for a duration of 24 hours, with covering of them with plastic sheets to protect against the quick evaporation of the mixing water from the top part of the mixtures. Following the demolding process, the specimens were subsequently immersed in a water vessel possessing a controlled environment and a temperature of 25±2°C for a period spanning 7 and 28 days. Each concrete mix was accommodated within three distinct types of molds. For the uniaxial compression test, cubic specimens with dimensions measuring 100×100×100mm were fabricated within cubic molds. Cylindrical specimens, measuring 100×200mm (diameter×height) were employed for the indirect tensile test. Furthermore, prismatic molds with dimensions of 100×100×400mm (width×height×length) were utilized to fabricate specimens designed for the four-point bending test.

Setup of Electrical Measurement during Mechanical Tests

The self-sensing characteristics of the mixtures were examined utilizing the fundamental principle of piezoresistivity, which involves quantifying the proportional alteration in electrical resistivity as described in equation 1, should be indented 5 mm (0,2”). There should be one line of space above the equation and one line of space below it before the text continues. The equations have to be numbered sequentially, and the number put in parentheses at the right-hand edge of the text. Equations should be punctuated as if they were an ordinary part of the text. Punctuation appears after the equation but before the equation number. The use of Microsoft equation is allowed when subjecting the specimen to an applied load. To assess the modification in electrical resistivity due to the application of load in this investigation, a two-probe DC method was employed. A highly accurate digital multimeter was connected to the brass electrodes to digitally record the electrical resistivity values at one-second intervals.

![]()

The variables FCER, RL, and RO represent fractional changes in electrical resistivity, electrical resistivity at a specified time under compression loading, and initial electrical resistivity, respectively.

The electrode placement in the fabricated specimens followed a parallel orientation concerning the load direction, as indicated by Al-Dahawi et al.(12) the insertion of these electrodes was carried out at the midsection of the pouring face of each specimen. For a visual presentation, refer figure 3 (a, b, c), which depicts the precise location of the two embedded electrodes in all types of specimens produced.

a) A cubic specimen b) A cylindrical specimen

c) A prismatic specimen

Figure 3. The locations of electrodes for all types of the produced specimens

Note: (All dimensions are in centimeters)

RESULTS AND DISCUSSION

Self-Sensing Behavior of Concrete Under load

The electrical resistivity has been instrumental in early crack detection within rigid pavements. This measurement provides a significant advantage by allowing the identification of cracks in their initial stages, enabling cost-effective maintenance before these cracks worsen and escalate into major issues. Consequently, timely detection and maintenance result in substantial cost savings, preventing the need for expensive repairs that would be necessary if the cracks were allowed to worsen over time.

In this research, sustainable concrete comprises Recycled Asphalt Pavement (RAP), fly ash, and silica fume, as each of these three materials has exerted a discernible influence on the results of FCER %. Fly ash can improve the electrical conductivity of concrete due to its pozzolanic nature and fine particle size. This enhanced electrical conductivity can be advantageous in self-sensing concrete as it enables the concrete to better detect changes in its structural properties, such as cracks and stress due to the changes happen to the electrical network created within the cementitious composites because of the addition and well dispersion of the added electrically conductive materials.

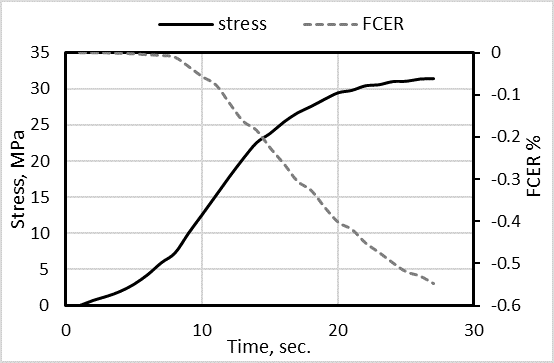

Self-Sensing Behavior Under Uniaxial Compression Test

The electromechanical test has provided crucial evidence regarding the piezoresistive behavior of the mixture. The concrete cube’s capacity to withstand mechanical stress has resulted in a measurable change in its electrical resistivity. As the load on the concrete cube has increased, there has been a systematic decrease/increase in electrical resistance depending on the direction of load application and its relationship with the electrical resistivity measurement. The progression of load application leads to the propagation of cracks.

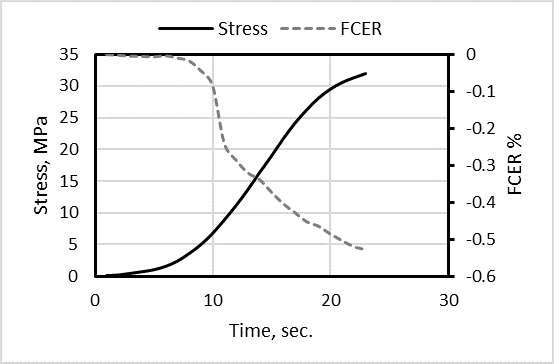

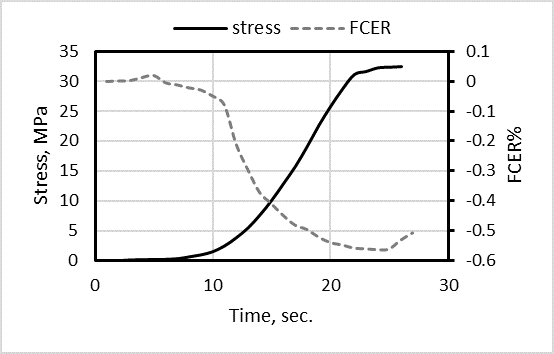

In figure 5, schematic curves have been used to illustrate the results acquired from an investigation into the self-sensing of sustainable concrete cube specimens as. The conductivity has been assessed through tests conducted in two orientations: one parallel to the copper electrodes embedded within the concrete and the other in the perpendicular direction. Comprehensive diagrams have been provided to illustrate the relationship between the applied stress, expressed in megapascals, the corresponding electrical resistance calculated as a percentage, and the time measured in seconds. factor the predominant dictating of the conductive characteristics lies in the orientation of the applied load on the copper electrodes. When the load aligns parallel to the electrodes, As the stress levels increase over time, there is a corresponding decline in the percentage of FCER the observed increase in conductivity can be ascribed to the cohesion exhibited by the concrete particles as the load increases as shown in figure 5 (a). It is noteworthy to highlight the positive impact of incorporating fly ash in the concrete mix, as it contributes to the self-sensing capabilities of the material. Fly ash, a byproduct of coal combustion, not only enhances the overall structural integrity of the concrete but also augments its ability to self-sense changes in conductivity because the distinctive morphology and size distribution of fly ash particles plays a significant role when introduced into concrete. Their incorporation can impact the microstructure of the material, fostering an interplay with the cement matrix. This interaction has the potential to establish a more interconnected and conductive network within the concrete.(6) Thereby further optimizing its performance resulting in enhanced self-sensing. Conversely, in the case when the load is perpendicular to the electrodes, the conduction rate is lesser compared to the former scenario. This is due to the diverging of the conduction electrodes. Due to the ejection that happened between concrete particles, thereby decreasing polarization and increasing the FCER % value as shown in figure 5 b.(26)

In figure 5 b, it has been observed that the percentage of change in FCER has remained small. This phenomenon is attributed to the inclusion of silica fume in the mixture during lower loads. The presence of silica fume renders the concrete more brittle. Consequently, the discernible percentage of change becomes apparent only when cracks develop in the mixture, a condition that typically arises under high load level.(27)

(a) The load application is parallel to the direction of measuring the electrical resistivity

(b) The load application is perpendicular to the direction of measuring the electrical resistivity

Figure 5. Self-sensing pattern of cubic specimens under compression loads with different scenarios of measuring the electrical resistivity

The self-sensing behavior in assessing split tensile strength

Specialized software DMM program has been employed to continuously monitor the splitting tensile behavior of a material subjected to an applied load. In order to obviate the transmission of direct current to the device, the strategic installation of a wooden pallet between the drum’s surface and the apparatus has been executed. This method is deployed for the explicit purpose of assessing the material’s response to tensile forces. Tensile strength, ascertained through this method, stands as a critical gauge of the material’s capacity to endure pulling or stretching forces without structural failure. It is worth noting that concrete, by its inherent nature, tends to develop fissures when subjected to tensile forces surpassing prescribed thresholds, thus highlighting its susceptibility to fragility under tension. The precise determination of tensile strength has assumed paramount importance, given that it defines the exact load threshold at which concrete may have exhibited crack formation and eventual failure. In this regard, periodic monitoring of electrical conductivity has been conducted to identify any incipient cracks within the concrete, emphasizing the ongoing and crucial nature of this process., thus enabling timely maintenance interventions before reaching the precipice of structural collapse.

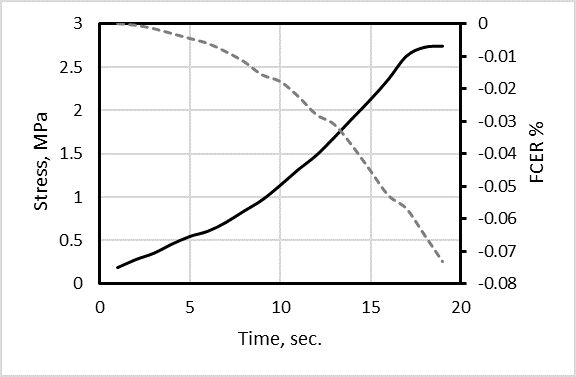

Figure 6 a, b displays the outcomes derived from the electromechanical examination of the concrete cylinder in figure 6 a. It was observed that in instances where the load was applied parallel to the electrodes, there was a corresponding decrease in FCER %, as the stress increased over time, measured in seconds. The observed augmentation in conductivity can be attributed to the growing cohesion among concrete particles with the escalating load as shown in figure 6 a.

(a) Load parallel to the electrodes (b) Load perpendicular to the electrodes

Figure 6. Self-sensing behavior of concrete under split tensile test

In figure 6 b It was observed that in instances where the load was applied perpendicular to the samples, there was a corresponding increase in FCER %, as the stress increased over time, measured in seconds This phenomenon arises from the diverging of conduction electrodes, driven by the Ejection force among particles due to compression stress. As a result, polarization minimizes while the FCER percentage value escalates as shown in figure 6 b.

It has been noted that there has been a minimal percentage change in FCER. This observation can be linked to the incorporation of silica fume in the mixture at lower loads. The addition of silica fume makes the concrete more brittle. As a result, noticeable changes in percentage become evident only when cracks form in the mixture, a situation that usually occurs under high load conditions.(27) To improve self-sensing fly ash has been used. The enhanced conductivity of concrete containing fly ash allows for better sensitivity to structural changes. When cracks or other forms of damage occur, they can disrupt the electrical pathways within the concrete, resulting in changes in conductivity. This makes it possible to detect issues more precisely and at an earlier stage.(28) Fly ash is a pozzolanic material that contains particles with a high surface area. When mixed with concrete, it can enhance the electrical conductivity of the composite material. The increased electrical conductivity allows for better detection of changes in electrical properties.(29)

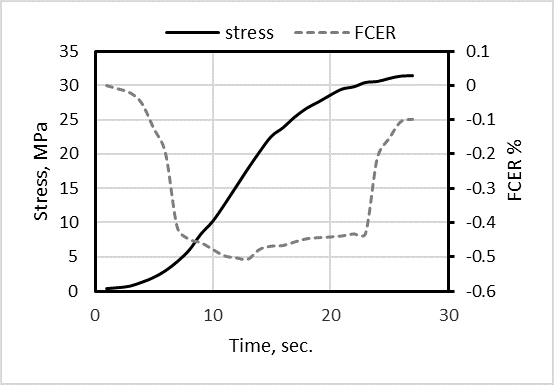

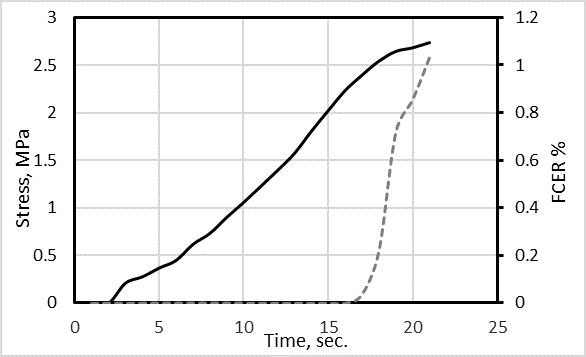

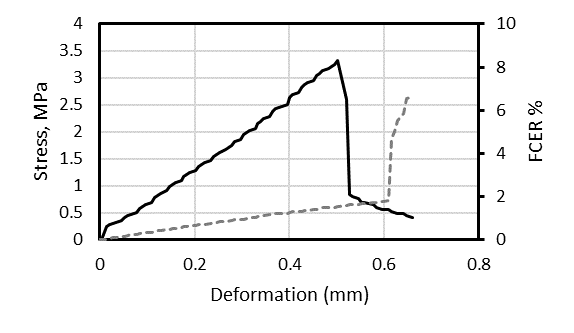

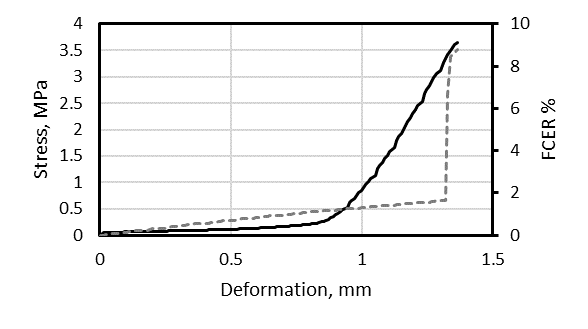

Behavior of self-sensing, load deflection, in prismatic samples under flexural strength

The flexural test has been of significant importance in assessing concrete’s capacity to bend and withstand vibrations. This test was conducted by applying a four-point load as prescribed by ASTM C78.(30) The concrete specimen has been positioned utilizing the WDW200 E apparatus, which boasts a 200 kN load capacity and operates at a velocity of 1 mm per minute. Simultaneously, the electrical conductivity and the electrical resistance of the concrete have been examined and expressed as a percentage (FCER %). Both the stress, measured in megapascals (MPa), and the resistivity have been assessed concerning the deformation in millimeters. Figure 8 has been utilized to depict the findings related to self-sensing within the context of four-point flexural strength. These figures allow for the assessment of self-sensing plots in three distinct segments by examining their variations in comparison to flexural stress-deformation plots. The first segment encompasses the range in which the flexural stress-deformation plot maintains linearity, commencing from the initiation of flexural loading and concluding with the emergence of the initial fracture (the elastic phase). The second phase commences with the onset of the first cracking and proceeds with a deflection hardening process characterized by the occurrence of numerous microcracks. The third segment represents the deflection-softening region, where a significant reduction in the load-bearing capacity under flexural stress is observed due to the localization of a specific microcrack, ultimately failing.(31,32) The flexural analysis has revealed intriguing findings. As shown in figure 8 As stress levels have intensified, the electric resistivity of FCER has shown a noticeable rise. However, upon reaching the critical failure point and the subsequent occurrence of fracture, an even more significant increase in resistivity has been observed. This phenomenon can be attributed to the divergence among concrete particles, resulting in reduced conductivity. The study has highlighted a correlation between stress-induced changes and the electrical properties of the material, shedding light on the intricate behavior of concrete under varying stress conditions.

Figure 8. Self-sensing behavior of concrete prismatic specimens under flexural load

Analyzing the Reaction of Concrete Pavements to Dynamic Truck Loads

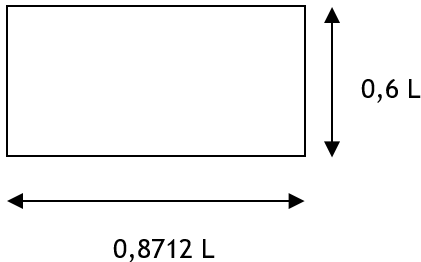

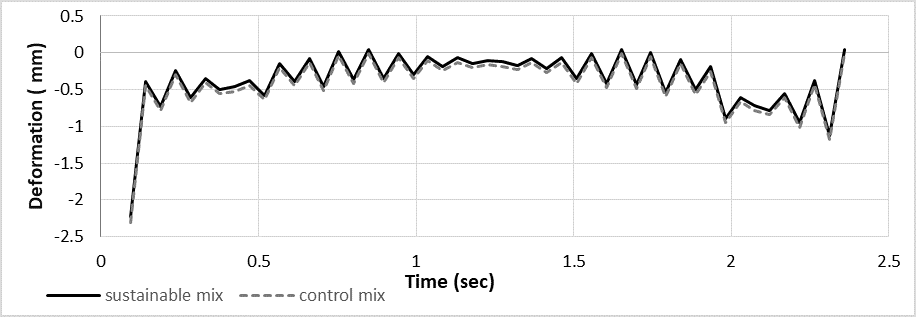

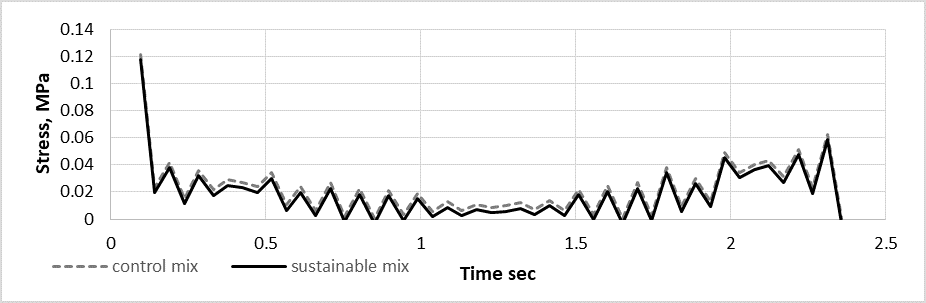

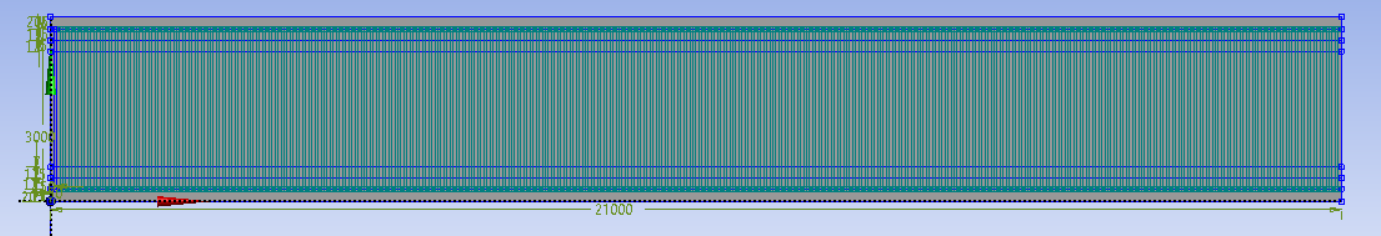

The behavior of a moving load was analyzed using ANSYS simulation software. Initially, the contact area of the tire was determined based on tire pressure, and it was assumed to have a rectangular shape, as illustrated in figure 9. The calculated contact area obtained using equation 2,(33) was 0,0393 square meters. Subsequent simulations were carried out for two different mixtures: one with a plain mix and the other incorporating sustainable self-sensing materials. The section dimensions used for the analysis were 21 meters in length and 3 meters in width as shown in figure 11. Upon reviewing the results, as depicted in figure 10, it became evident that the mixture containing sustainable materials exhibited a slight improvement in terms of resistance deformation and shear stress when compared to the plain mix. This observation suggests that the incorporation of sustainable materials positively influences the mechanical behavior of the structure under the moving load, indicating its potential to enhance the overall performance and durability of the material composition.

![]()

Ac = contact area, which can be obtained by dividing the load on each tire by the tire pressure.

Figure 9. Dimension of tire contact area(33)

(a)

(b)

Figure 10. Time histories of slab deflection (a) and stress (b)

Figure 11. Slab and mesh configurations

CONCLUSIONS

This research explores the self-sensing behavior of concrete under load, emphasizing the importance of electrical resistivity in early crack detection within concrete structures. Timely detection and maintenance, made possible by measuring electrical resistivity, can result in substantial cost savings and prevent the escalation of minor issues into major problems. So, some conclusions can be drawn.

The use of sustainable resources including fly ash into the concrete mix has improved self-sensing capability, consequently enhancing its self-sensing capabilities. The specific shape and size distribution of fly ash particles play an important function in the concrete mixture. The incorporation of fly ash can change the microstructure of the material, allowing for a dynamic interaction within the cement matrix. This interaction, in turn, can form a more connected and conductive network through the concrete, further increasing its self-sensing properties. The findings show that the direction of the applied load on the copper electrodes affects the conductivity of the concrete in the cubes. Because of the cohesive nature of concrete particles, parallel loads indicate higher conductivity, whereas vertical loads exhibit lower conductivity. Incorporating Recycled Asphalt Pavement (RAP), Fly ash, and silica fume. Fly ash, with its enhanced electrical conductivity, plays a vital role in enabling concrete to detect changes in its structural properties such as cracks and stress. The research categorizes the conductivity test into different types based on the configuration of the concrete specimen

When a load is applied perpendicular to the poles, the electrical conductivity of the concrete cylinders tends to rise. This implies that electrical pathways become more favorable to electron flow in this orientation, or that the material’s structure becomes less obstructive to electron flow. Because the weight compresses the concrete particles, the inter-particle distances are reduced. This compression brings the conductive particles closer together, lowering electron flow resistance and increasing electrical conductivity.

The FCER (Fracture Critical Energy Release), in the concrete prism, has increased with the application of additional load until reaching the point of failure. Notably, it exhibited a more significant increase after the fracture occurred due to the formation of cracks, which led to the separation of concrete particles.

The mixture containing sustainable materials, including silica fume and fly ash, exhibited a noticeable improvement in terms of resistance to deformation and shear stress when compared to the plain mix. This finding suggests that the incorporation of these sustainable materials has a positive impact on the mechanical behavior of the structure under a moving load, hinting at its potential to enhance the overall performance and durability of the material composition and one of the reasons for this improvement that silica fume has the potential to make a substantial contribution to the improvement of concrete’s mechanical properties. The combination of silica particulates with water, in conjunction with the presence of calcium hydroxide resulting from cement hydration, triggers a pozzolanic reaction. This reaction, in turn, leads to the generation of a greater quantity of calcium silicate hydrate (C-S-H) gel.

BIBLIOGRAPHIC REFERENCES

1. Brunner, P.H. and H. Rechberger, Handbook of material flow analysis: For environmental, resource, and waste engineers. 2016: CRC press.

2. Al-Dahawi, A., et al., Assessment of self-sensing capability of Engineered Cementitious Composites within the elastic and plastic ranges of cyclic flexural loading. Construction and Building Materials, 2017. 145: p. 1-10.

3. Yıldırım, G., et al., Piezoresistive behavior of CF- and CNT-based reinforced concrete beams subjected to static flexural loading: Shear failure investigation. Construction and Building Materials, 2018. 168: p. 266-279.

4. Sarwary, M.H., et al., Self-Sensing of Flexural Damage in Large-Scale Steel-Reinforced Mortar Beams. ACI Materials Journal, 2019. 116(4): p. 209-221.

5. Hanjitsuwan, S., P. Chindaprasirt, and K. Pimraksa, Electrical conductivity and dielectric property of fly ash geopolymer pastes. International Journal of Minerals, Metallurgy, and Materials, 2011. 18(1): p. 94-99.

6. Saafi, M., et al., Graphene/fly ash geopolymeric composites as self-sensing structural materials. Smart materials and structures, 2014. 23(6): p. 065006.

7. Mizerová, C., et al., Self-sensing properties of fly ash geopolymer doped with carbon black under compression. Materials, 2021. 14(16): p. 4350.

8. Dong, W., et al., Effects of silica fume on physicochemical properties and piezoresistivity of intelligent carbon black-cementitious composites. Construction and Building Materials, 2020. 259: p. 120399.

9. Faghih, F. and A.S. Ayoub, Mechanical and self-sensing properties of concrete reinforced with carbon nanofibres. Advances in Cement Research, 2021. 33(3): p. 97-113.

10. Imbabi, M.S., C. Carrigan, and S. McKenna, Trends and developments in green cement and concrete technology. International Journal of Sustainable Built Environment, 2012. 1(2): p. 194-216.

11. Bendapudi, S.C.K. and P. Saha, Contribution of fly ash to the properties of mortar and concrete. International Journal of Earth Sciences and Engineering, 2011. 4(6): p. 1017-1023.

12. Al-Dahawi, A., et al., Electrical percolation threshold of cementitious composites possessing self-sensing functionality incorporating different carbon-based materials. Smart Materials and Structures, 2016. 25(10): p. 1-15.

13. Al-Najjar, Y., et al., Physical and Chemical Actions of Nano-Mineral Additives on Properties of High-Volume Fly Ash Engineered Cementitious Composites. ACI Materials Journal, 2016. 113(6): p. 791-801.

14. Arulrajah, A., et al., Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications. Journal of Materials in Civil Engineering, 2013. 25(8): p. 1077-1088.

15. Al-Azawee, E.T., Z.I. Qasim, and A.M. Al-Dahawi, Evaluation of mechanical and durability properties of rubberized hot mix asphalt. AIP Conference Proceedings, 2023. 2775(1): p. 060023.

16. Hower, J.C., et al., Mercury capture by native fly ash carbons in coal-fired power plants. Progress in Energy and Combustion Science, 2010. 36(4): p. 510-529.

17. Specification, I., No. 5, Portland Cement. Iraqi Specif., Iraqi Specifications, 1984.

18. ASTM-C150, Standard specification for Portland cement, in Annual book of ASTM standards. 2007. p. 8.

19. Neville, A.M., Properties of concrete. Vol. 4. 1995: Longman London.

20. ASTM-C618, Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete, in Annual book of ASTM standards. 2005. p. 3.

21. Neville, A., Properties of concrete (vol. 4): Longman london. 1995.

22. Zhang, Z., B. Zhang, and P. Yan, Comparative study of effect of raw and densified silica fume in the paste, mortar and concrete. Construction and Building Materials, 2016. 105: p. 82-93.

23. ASTM-C1240-20, Standard Specification for Silica Fume Used in Cementitious Mixtures. 2020, ASTM: USA. p. 7.

24. Kadhim, A., A.M. Al-Dahawi, and Q.S. Banyhussan. Mechanical and Piezoresistive Properties of Fibre Reinforced Concrete Pavement. in IOP Conference Series: Materials Science and Engineering. 2021. IOP Publishing.

25. Al-Dahawi, A., et al., Effect of mixing methods on the electrical properties of cementitious composites incorporating different carbon-based materials. Construction and Building Materials, 2016. 104: p. 160-168.

26. Suri, L.N., et al., Adaptation to low body temperature influences pulmonary surfactant composition thereby increasing fluidity while maintaining appropriately ordered membrane structure and surface activity. Biochimica et Biophysica Acta (BBA)-Biomembranes, 2012. 1818(7): p. 1581-1589.

27. Kathirvel, P. and G. Murali, Effect of using available GGBFS, silica fume, quartz powder and steel fibres on the fracture behavior of sustainable reactive powder concrete. Construction and Building Materials, 2023. 375: p. 130997.

28. Paya, J., et al., Enhanced conductivity measurement techniques for evaluation of fly ash pozzolanic activity. Cement and Concrete research, 2001. 31(1): p. 41-49.

29. Das, B. and S. Pandey, Influence of fineness of fly ash on the carbonation and electrical conductivity of concrete. Journal of materials in civil engineering, 2011. 23(9): p. 1365-1368.

30. Concrete, A.I.C.C.o. and C. Aggregates, Standard Test Method for Flexural Strength of Concrete (using Simple Beam with Center-point Loading). 2010: ASTM international.

31. Al-Dahawi, A., Multifunctional Cementitious Composites for Damage-Resistant Highway Structures. 2016, Civil Engineering, Univesity of Gaziantep Gaziantep, Turkey.

32. Al-Dahawi, A.M. Effect of curing age on the self-sensing behavior of carbon-based engineered cementitious composites (ECC) under monotonic flexural loading scenario. in MATEC Web of Conferences. 2018. EDP Sciences.

33. Das, A., Analysis of pavement structures. 2023: CRC Press.

FINANCING

The authors did not receive financing for the development of this research.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

AUTHORSHIP CONTRIBUTION

Conceptualization: Mohammed Refat, Ali M. Al-Dahawi, Husam Hikmat Baqir.

Data curation: Mohammed Refat, Ali M. Al-Dahawi, Husam Hikmat Baqir.

Formal analysis: Mohammed Refat, Ali M. Al-Dahawi, Husam Hikmat Baqir.

Research: Mohammed Refat, Ali M. Al-Dahawi, Husam Hikmat Baqir.

Methodology: Mohammed Refat, Ali M. Al-Dahawi, Husam Hikmat Baqir.

Drafting - original draft: Mohammed Refat, Ali M. Al-Dahawi, Husam Hikmat Baqir.

Writing - proofreading and editing: Mohammed Refat, Ali M. Al-Dahawi, Husam Hikmat Baqir.