Category: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

A Comprehensive Investigation of Brushless Direct Current (BLDC) Motors: Current State, Advanced Control Strategies, and Utilization Systems

Investigación exhaustiva de los motores de corriente continúa sin escobillas (BLDC): Estado actual, estrategias de control avanzadas y sistemas de utilización

Suhair Akram1 *, Mohanned Aljanabi1 *

1Department of Electrical Engineering Techniques, Researchers from Al-Mussaib Technical college, Al-Furat Al-Awsat Technical University. 51009 Babylon, Iraq.

Cite as: Akram S, Aljanabi M. A comprehensive investigation of brushless direct current (bldc) motors: current state, advanced control strategies, and utilization systems. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:865. https://doi.org/10.56294/sctconf2024865

Submitted: 05-02-2024 Revised: 16-04-2024 Accepted: 07-06-2024 Published: 08-06-2024

Editor: Dr.

William Castillo-González ![]()

Note: paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

In the field of dynamic applications, specifically within automotive, pumping, and rolling sectors, there exists a noteworthy preference for the use of Brushless Direct Current (BLDC) motors. Projections show that, by the year 2030, BLDC motors are poised to supersede classic induction motors as the dominating force in industrial power transmission. This transformation, however, is accompanied by crucial issues and unresolved research challenges in the environment of BLDC motors.

The core concern revolves around the dependability and endurance of BLDC motors. These motors presently encounter obstacles in achieving advanced fault tolerance, reduced electromagnetic interference, lowered acoustic noise, as well as mitigated flux and torque fluctuations. The path of closed-loop vector control emerges as a possible technique to address these challenges.

In recent literature studies spanning the previous five years, a striking scarcity of exploration in the domain of BLDC motor controllers and design becomes clear. Furthermore, key areas such as the comparative study of existing vector control schemes, the increase of fault tolerance control, the attenuation of electromagnetic interference inside BLDC motor controllers, and other pivotal elements remain undiscovered. These research lacunae serve as a motivator for the undertaking of an intensive investigation to face the fundamental issues related with BLDC motors. BLDC motors have quickly become the motor of choice for electric vehicle (EV) applications due to the fact that they are reliable, simple, and energy efficient.

This detailed survey goes deep into numerous sophisticated control strategies for BLDC motors. These encompass fault tolerance control, electromagnetic interference reduction, field orientation control (FOC), direct torque control (DTC), current shaping, input voltage control, intelligent control, drive-inverter topology, and the underlying operational principles aimed at the minimization of torque irregularities. Additionally, the study goes through the historical narrative of BLDC motors, the categorization of BLDC motor kinds, their structural complexity, mathematical modeling, and the standards that govern BLDC motor uses in varied industries.

Keywords: BLDC Motor; Torque Ripple; Current Shaping Techniques; Controlling Input Voltage; Direct Torque Control.

RESUMEN

En el campo de las aplicaciones dinámicas, concretamente en los sectores de la automoción, el bombeo y la rodadura, existe una notable preferencia por el uso de motores de corriente continua sin escobillas (BLDC). Las previsiones muestran que, para el año 2030, los motores BLDC están a punto de desbancar a los motores de inducción clásicos como fuerza dominante en la transmisión de potencia industrial. Esta transformación, sin embargo, va acompañada de problemas cruciales y retos de investigación sin resolver en el entorno de los motores BLDC.

La principal preocupación gira en torno a la fiabilidad y resistencia de los motores BLDC. En la actualidad, estos motores se enfrentan a obstáculos para conseguir una tolerancia avanzada a los fallos, reducir las interferencias electromagnéticas y el ruido acústico, así como mitigar las fluctuaciones de flujo y par. La vía del control vectorial en bucle cerrado emerge como una posible técnica para abordar estos retos.

En los estudios bibliográficos recientes, que abarcan los últimos cinco años, se pone de manifiesto una sorprendente escasez de exploración en el ámbito de los controladores y el diseño de motores BLDC. Además, quedan por descubrir áreas clave como el estudio comparativo de los esquemas de control vectorial existentes, el aumento del control de tolerancia a fallos, la atenuación de las interferencias electromagnéticas en el interior de los controladores de motores BLDC y otros elementos fundamentales. Estas lagunas en la investigación sirven de motivación para emprender una investigación intensiva con el fin de afrontar las cuestiones fundamentales relacionadas con los motores BLDC. Los motores BLDC se han convertido rápidamente en los motores preferidos para aplicaciones de vehículos eléctricos (VE) debido a su fiabilidad, sencillez y eficiencia energética.

Este estudio detallado profundiza en numerosas y sofisticadas estrategias de control para motores BLDC. Entre ellas se incluyen el control de tolerancia a fallos, la reducción de interferencias electromagnéticas, el control de orientación del campo (FOC), el control directo del par (DTC), la conformación de la corriente, el control de la tensión de entrada, el control inteligente, la topología del convertidor y los principios operativos subyacentes destinados a minimizar las irregularidades del par. Además, el estudio repasa la narrativa histórica de los motores BLDC, la categorización de los tipos de motores BLDC, su complejidad estructural, el modelado matemático y las normas que rigen los usos de los motores BLDC en diversas industrias.

Palabras clave: Motor BLDC; Ondulación del Par; Técnicas de Conformación de Corriente; Control de la Tensión de Entrada; Control Directo del Par.

INTRODUCTION

T. G. Wilson and P.H. Trickey set out to power Direct Current (DC) motors using solid-state commutation around fifty years ago in a series of studies. An innovation based on Lorentz's force law, the Brushless Direct Current (BLDC) motor(1) was developed from these ground-breaking works. When it comes to pushing the automotive industry toward more widespread use of electric vehicles, BLDC motors have been the center of intense research efforts for the last several decades.

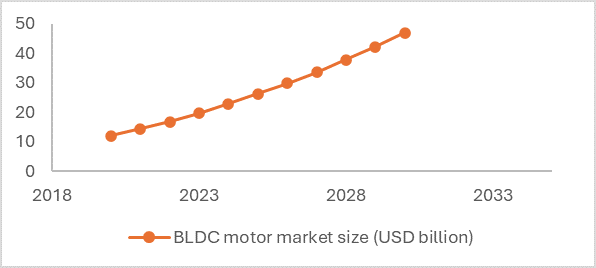

The automotive, pumping, and rolling sectors are just a few of the many that have found uses for BLDC motors because of their small size, lightweight construction, and great agility.(2) The next decade is going to see an explosion in the demand for electric vehicles, and BLDC motors will play a key part in meeting that demand. The predicted growth of the BLDC motors market from 12,1 billion USD in 2020 to a whopping 47 billion USD by 2030 (as shown in figure 1) is indicative of this trend. There has been an explosion in applications due to this large growth.(3)

Figure 1. BLDC motor market size estimations

A variety of tasks, including lifting, cutting, and bracing, are well-suited to BLDC motors.(4) A strong magnetic coupling is essential for efficient operation, and that is exactly what they are made to do. We anticipate that BLDC motors will outperform competing motors in terms of efficiency, torque-to-weight ratio, and noise level reduction.(5) Their ability to operate efficiently at unity power factor is characterized by the stationary magnetic flux between the rotor and stator. The electronic controllers used by these motors allow for exact control of speed and torque by current pulses; nevertheless, this precision can lead to increased wear when subjected to heavy use.(6)

Hall Effect sensors or sensor less methods are used by BLDC motors to detect the position of the rotors. Techniques such as the EMF zero-crossing approach are commonly used in sensor less methods,(7,8) while the observer-based EMF method and the magnetic anisotropy method are also viable options. These methods are less responsive but well-suited to high-power environments like electric trains and aircraft.

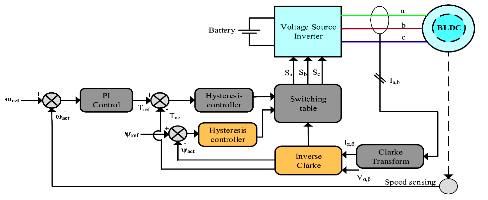

Controlling motor speed and commutation logic efficiently is the goal of motor control. The hysteresis band current, stator currents, and rotor position are all inputs that come from the motor and drive. The proper spinning of a motor depends on the precise control of its switches.(9) If you want to manage the harmonic content of the power supply, you should use pulse width modulation (PWM) methods, particularly space vector PWM (SVPWM). When combined with pulse width modulation (PWM) and hysteresis controllers, the current control schemes greatly enhance the performance of motor drives. Modals such as H-PWM-L-ON, H-ON-L-PWM, ON-PWM, PWM-ON, PWM-ON-PWM, and H-PWM-L-PWM are available for use in unipolar pulse width modulation current control.

In comparison to induction motors, Brushless Direct Current (BLDC) motors don't last nearly as long, despite being much more efficient.(10) We look at fault tolerance, electromagnetic interference, acoustic noise, torque, and flux ripple as important difficulties that need to be addressed in order to improve the endurance of BLDC motors.

Motor drives must incorporate reliability control methods since BLDC motors are commonly used in dynamic applications. Improve the performance of motor drive systems in dynamic situations with techniques including fault-tolerant control (FTC), electromagnetic interference control (EMI), and acoustic noise reduction. It is crucial to have preventative fault control as producing acoustic noise and electromagnetic interference might cause motor problems. In order to keep operations running smoothly, the study explores different control strategies that are used to reduce EMI and acoustic noise. Fault tolerance measures are also put into place as backups.

Using a quick counter to identify defects when the threshold value is exceeded is the method used in Donato et al.(11) for fast fault diagnostics. Nevertheless, applications requiring great acceleration might not be a good fit for this method. Separately, Ming et al.(12) examines the frequency domain analysis of the direct current (dc) bus voltage with an eye toward EMI reduction. Motor structure can have a major effect on EMI generation, according to this investigation. Table 1 provides an overview of the extensive literature review that was carried out for this article.

|

Table 1. Comprehensive and brief literature survey |

||||||

|

Ref. |

Topology |

Techniques |

Motor Type |

Applications |

Reliability |

Torque Ripple Mitigation |

|

(13) |

Fault-tolerant control (FTC) |

Sensory fault detection using discrete Fourier transform. |

10 poles, 3 phase BLDC |

Industrial, Commercial |

✓ |

-- |

|

(14) |

Electromagnetic interference (EMI) |

Use of LISN network to reduce load parasitic elements. |

4 poles, 3 phase BLDC |

Commercial |

✓ |

-- |

|

(15) |

Torque ripple reduction (Scalar) |

Modulating current wave of power supply. |

4 poles, 3 phase BLDC |

Industry |

-- |

✓ |

|

(16) |

Torque ripple reduction (Vector) |

Torque ripples minimized using MPC Scheme. |

8 poles, 3 phase BLDC |

Industry |

-- |

✓ |

Designing motors with structural symmetry and optimal alignment of stator poles in mind helps avoid torque ripples. Reducing cogging torque is one of the main causes of ripple generation, which impacts EMI interference and acoustic noise within the machine. Interactions between the stator's silicon core and the permanent magnet are the main causes of cogging torque. Cogging torque ripples can be mitigated in the design process through the following methods: feedback linearization algorithms, T-shaped bifurcations in stator slots, sliding separators to close slots, rotor notches for low-power motors, coil winding concentration within the same phase group, smaller claw poles, magnet step skewing techniques, U-shaped magnetic poles. Additional harmonics, decreased mechanical strength, and increased structural complexity are some of the downsides that occur with each technique.(17)

Reduced torque ripple and superior dynamic response under varied demanding conditions are achieved by vector control approaches such as field orientation control (FOC), direct torque control (DTC), and Model Predictive Control (MPC) schemes. Drives based on FOC first appeared in 1972, whereas drives based on DTC first appeared in 1986. Later developments in embedded controller technology greatly enhanced motor controllers' dynamic response and steady-state capabilities. Further improvements to dynamic response have been made possible by novel computing techniques, such as intelligent control algorithms, particle swarm optimization, extended Kalman filter algorithms, fuzzy logic estimates, and finite control set MPC.(18)

METHOD

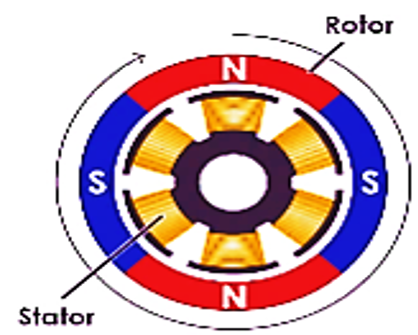

The physical design of BLDC motors can be broadly categorized into two key components: the stator and the rotor

Designing motors with structural symmetry and optimum stator pole alignment reduces torque ripples. These methods lower cogging torque, a major cause of ripple generation, which reduces machine acoustic noise and EMI interference. The permanent magnet-stator silicon core interaction causes cogging torque. Feedback linearization algorithms, T-shaped bifurcations in stator slots, sliding separators, notches in the rotor for low-power motors, coil winding concentration within the same phase group, claw pole size reduction, magnet step skewing methods, and U-shaped magnetic poles are among the design strategies for reducing cogging torque ripples. Each method has limitations such harmonics, mechanical weakness, and structural complexity.(18)

Vector control techniques like FOC, DTC, and MPC are also popular for reducing torque ripple and improving dynamic responsiveness under demanding conditions. DTC drives debuted in 1986, while FOC drives debuted in 1972. Later embedded controller development increased motor controller steady-state and dynamic response. Dynamic response has improved using finite control set MPC, intelligent control algorithms, particle swarm optimization, expanded Kalman filter methods, and fuzzy logic estimates.(17)

This paper summarizes the latest BLDC motor drive control technology and BLDC motor research. The study also covers mathematical modeling of motors and motor drives, reliability control methods such LISN EMI filtering, cost observer fault-tolerant control, and field-programmable gate array controller acoustic noise management. Compare and contrast fault-tolerant control and EMI suppression strategies in the study,

We analyze BLDC motors and the state of the art. Figure 2 shows that outer rotor-type BLDC.

Figure 2. Outer rotor-type BLDC

However, Jung et al.(19) discusses inner rotor BLDC motor design. This study examines ferrite-bonded BLDC motors using finite element analysis. Experimental results show that inner rotor motors have good power characteristics under dynamic situations. A preliminary method for high-speed ferrite-based BLDC motors improves magnetic flux components through mechanical constraint changes.

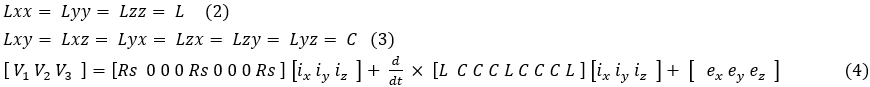

Mathematical BLDC modeling enables design and analysis. Back EMF can estimate position.(19) In a 3-phase BLDC, induced rotor currents are neglected due to high magnet resistivity.

![]()

Where V1, V2, and V3 are the phase voltages of the BLDC motor, Rs is the stator resistance, ia, ib and ic are the stator currents, Lxx, Lyy and Lzz are the stator self-inductances, and ex, ey, and ez are the back EMFs. If we assume the resistances are equal and the reluctance between the stator and rotor is negligible (i.e. no variation with rotor angle), then:

Since the motor is star connected. The stator currents are considered to be balanced.

![]()

This is used to simplify the inductance matrix as:

![]()

Therefore, the main equation becomes:

![]()

Since the back EMF of BLDC motor is trapezoidal. The back EMF equations are given as:

![]()

Where ωm is the rotating speed of the motor, λm is the flux linkage of the motor, and Fxs(θr), Fys(θr) and Fzs(θr) represent back EMF functions at different magnitude instants. The flux linkages between the stator and rotor are smoothed. Therefore, the electromagnetic torque developed by the BLDC motor is given by:

![]()

The resulting phase voltage equation resembles the armature voltage equation of a direct current machine.

The equation of motion for the motor drive is:

![]()

Where J is the combined inertia, F is the mechanical friction coefficient. The mechanical speed of the motor is related by:

![]()

Where P is the number of poles of the motor.

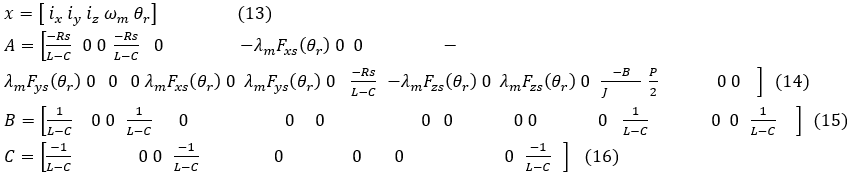

Combining all the relevant equations, the system in state space equation becomes:

![]()

Where:

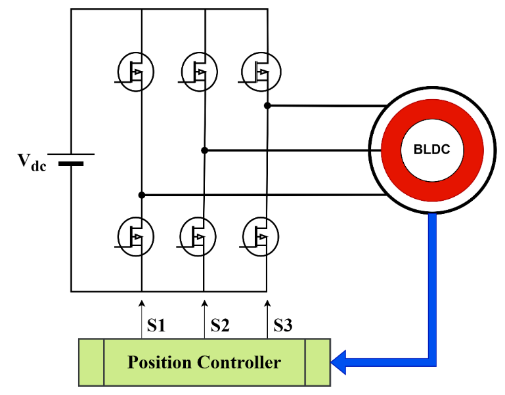

Figure 3 shows the BLDC motor's scalar control power circuit. This setup uses Insulated Gate Bipolar Transistor (IGBT) power switches (T1–T6) controlled by Pulse Width Modulation (PWM) signals (denoted as Sx, Sy, Sz).

Figure 3. Scalar control of the BLDC motor

This approach allows future integration of several BLDC motors, reducing motor transmission losses. Additionally, motor drive systems can be radially housing-mounted, radially stator iron-mounted, axially housing-mounted, or axially stator iron-mounted. Figure 4 depicts the combined motor drive.

Figure 4. Mounted axial flux integrated inverter of BLDC(8)

In the course of evaluating the diverse configurations and architectures of BLDC motors, it is imperative to address a multitude of technical challenges that are integral to the design and construction phases of BLDC motors.

Mass Reduction

The motor under design should be light. It has applications in traction, pumping, and domestic utilities. The weight of a motor depends on its use, although a lighter motor is more adaptable and can be used for many purposes. Mass reduction and volume minimization are linked. In power tools, the motor must be compact and function well. As stated by Buja et al.(15), the motor must be small.

Enhanced Efficiency

Switching from induction motors to Brushless DC (BLDC) motors improves performance efficiency. As shown by Darba et al.(16), this increase requires a motor with reduced torque fluctuations, superior flux linkage, and thermal stability.

Cost Efficiency

BLDC motors work with motor drives, which can be integrated or separate. Motors and drives are expensive. Separating the drive requires more cabling, cables, and connectors, which increases installation costs. As stated by Yazdan et al.(17), motor design cost reduction involves careful material selection and use during manufacture.

Enhanced Fault Resilience

To enable power switch commutation in BLDC motor engineering, rotor position must be correctly determined. Hall sensors, speed sensors, stator flux coils, and others are used. In demanding applications like electric vehicle traction systems, rotor position sensor failure can make operation difficult. As mentioned by Yazdan et al.(17), the motor's fault tolerance must be increased to ensure reliable performance under various conditions.

Enhanced Thermal Resilience

Technology advancements are needed to improve system thermal resilience. Winding materials with low resistance, a stator core with high flux linkage, and an internal permanent magnet with high flux linkage increase thermal robustness. Fortifying the cooling process can increase thermal resilience under certain conditions. In static conditions, motor driving devices are combined with motors, which may cause high thermal temperatures. Therefore, the system needs proper cooling.(18)

Reduced Acoustic Emission

In BLDC motors, the genesis of acoustic noise can be attributed to electromagnetic forces, the structural configuration, and the emergence of odd harmonics within the motor windings. An optimally designed BLDC apparatus exhibits diminished acoustic emissions. These emissions can be further attenuated by appropriately skewing the rotor and stator slots and by timely commutation of the power switch.(18)

Elevated Vibrational Activity

When drives operate a motor, the cable between the drive and motor induces common-mode voltages and bearing currents in the motor's yoke. Frosting and spark traces on bearings increase motor vibration. Grounding devices, using dv/dt filters, and using EMI filters can reduce these impacts.

Decline in Power Electronics Expenditure

Employing power electronics drives for industrial or domestic objectives can elevate the cumulative cost of the system. These motor drives might be incorporated with motors or positioned independently. The expense diminution is influenced by principal determinants like materials, fabrication techniques, standardization, and modular design.(20) Given the multifaceted challenges and the contemporary advancements in BLDC motors, an examination of the diverse applications and international benchmarks of BLDC motors is presented in the subsequent section.

RESULTS AND DISCUSSION

System efficiency is crucial to product viability. Regional governments set motor efficiency norms. In Europe, the International Electro-Technical Commission (IEC) sets standards, while in the US, NEMA does. IEC motor standards have four levels.(19)

The efficiency classes under IEC 60034-30-1 are segregated into four categories:

1. IE1 (standard efficiency)

2. IE2 (high efficiency)

3. IE3 (premium efficiency)

4. IE4 (super premium efficiency)

By the standards, the efficiency of a motor, whether operating at 50 Hz or 60 Hz, with single-phase or three-phase windings and constructed with the BLDC motor drive boasting an output power exceeding 120W, is determined.

Guidelines for motor efficiency standards have been stipulated by the National Electrical Manufacturers Association (NEMA) of the United States of America. These standards are distinguished as:

1. Old Standard Efficiency Motor.

2. Prior NEMA EE.

3. NEMA Energy.

4. NEMA Premium.

Similar to the International Electro-Technical Commission standards, an escalation in output power also results in a rise in the efficiency requirements according to NEMA standards. Assumptions for the majority of the standards are formed under the premise that each motor drive is fabricated and

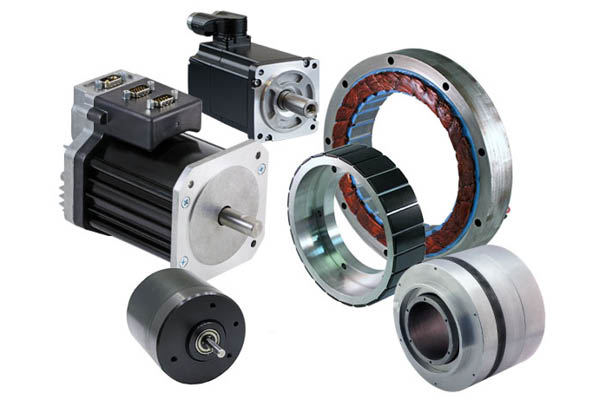

Owing to their benefits, such as a high torque-weight ratio and compactness, both inner and outer rotor-based BLDC motors are deployed across varied applications. However, contingent upon the requisite speed brackets—less than 500rpm, 501 to 2000 rpm, 2001 to 10000rpm, and above 1000rpm—particular BLDC motor types are opted for designated applications.

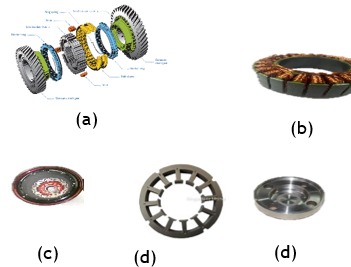

Electric Cars

The first half of the decade saw a strong increase in electric car sales in many countries. Over 10 million electric vehicles are on the road, with 47 % from China. Electric vehicles account for over 1 % of market share in some countries. BLDC motors are preferred for lightweight electric cars. Electric scooters use BLDC hub motors because they are retrofit table. BLDC hub motors use sensor-based and sensor-less motor controls. Hub motors in lightweight electric vehicles increase Back EMF by 3 %.(24) Hub motors have drawbacks, such as increased weight on the power-driven side limiting vehicle stability, difficulty maintaining torque, and higher mechanical stress than normal BLDC motors. EV BLDC motors meet IE-2, IE-3, or IE-4 efficiency criteria. The BLDC hub motor's structure and components are shown in figure 5. Since motor controller specifications are not standardized, various manufacturers have created two-wheeler electric cars with proprietary standards.

Figure 5. (a) Hub motor structure. (b) Stator winding Connection (c) Tire rim (d) Without stator winding (e) Motor rear cover

Examples include operating voltages of 24 V and 48 V, battery capacities ranging from 40Ah-100Ah, and motor power up to 6 kW. Yet, the application of BLDC motors is not solely confined to power transmission in electric vehicles; they also find utility in turbochargers, blowers, and seat comfort systems.(20)

Enhanced fault tolerance, reduced EMI, and torque and flux ripple curtailment boost BLDC motor dependability in EV applications. In electric cars, conducted emission sources are often defined within a frequency domain, which may cause system distortions. The causes of EMI, notably cable-propagating EMI, and mitigating methods are discussed by Anuja et al.(20) Power lines generate EMI owing to conductive components and discordant frequencies. Anticipating distributed element characteristics that match the system's frequency reduces EMI, improving BLDC motor framework dependability. More importantly, fault tolerance increases system reliability. Anuja et al.(20) presents a fast defect detection system for BLDC motors in EVs. Uneven machine speed, back EMF variations, and phase sequence changes indicate stator problems in BLDC motors, indicating fault identification. As explained later, model-based methods orchestrate efficient FTCs. BLDC motor torque ripples in EV frameworks cause shaft failures, increased vibrations, and aural disturbances. The DTC algorithm compensates stator iron losses and increases torque per ampere to reduce torque and flux ripples.

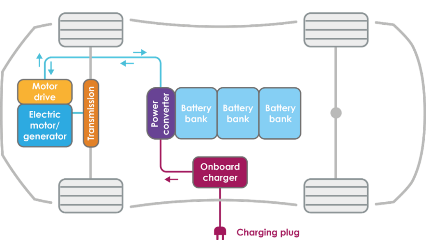

Future advancements in EVs emphasize multi-motor setups. Thus, this discourse illuminates BLDC motor-powered electric cars with wheel-mounted motors. These multi-motor designs' merits and downsides are also discussed. the electric cars with four hub wheel motors emit more noise and torque ripple during low-speed operations, requiring vector control methods. Multiple motor regenerative braking systems store more energy than single motor ones. The e-differential approach is conceptualized by Jung et al.(19) using Ackerman-Jintao geometry. A multi-drive system's electrical differential is schematically shown in figure 6.

Figure 6. A block diagram of the electrical differential for electric vehicle

Water Pumping

Due to their energy efficiency, BLDC motors are used for pumping. Standards are chosen depending on electricity needs. Low-power pumping apps use IE-1, whereas medium- and high-power applications use IE-2 and IE-3. BLDC motors are typically paired with renewable energy sources like solar energy.

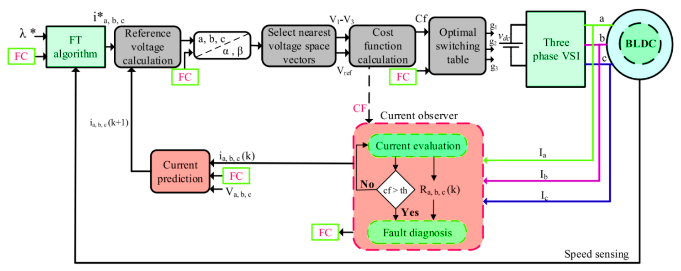

Fault-Tolerance Control

Fault tolerance control (FTC) is crucial, especially for intricate tasks like electric cars and robotics. Four fault types in BLDC drives are recognized: (i) power switch open, (ii) power switch short, (iii) DC-link capacitor short, (iv) hall-sensor fail. Four FTC methods exist: (1) replication, (2) oblivious computing, (3) recovery shepherding, and (4) circuit breaker. In BLDC systems, replication is used. It involves multiple system versions, switching to another if one fails. A model-based tactic is usually chosen for effective FTC. It hinges on system predictions and cost function (CF) estimations. If CF and the model differ, a fault code emerges, triggering FTC. Figure 7 depicts FTC's basic structure.

Figure 7. Technique of Fault-tolerant control

Sensor failures effect BLDC gate pulses. In Sun et al.(21), LRGF neural networks detect faults. Compare to a conventional motor drive. If problems arise, adaptive controls act. This neural tool detects voltage driver leakage and other issues. In BLDC motor hall-effect sensor problems are examined. Tests include x-rays and sensor corrosion. The post-corrosion sensor validity is checked.

It compares normal and abnormal gate pulse timings. This system uses two hall sensors. If one fails, another takes over. A technique detects BLDC motor stator defects in Anuja et al.(20). Normal and defective stator currents differ in energy utilization. Speed is guaranteed by a wavelet speed controller. The simultaneous flaws are examined. Hall sensor time transitions are determined properly. When thresholds and real-time signals disagree, signals are reconstructed. In Perotti et al.(14), torque and power-focused multiphase motor FTC is discussed. Healthy currents guide faulty ones. BLDC reduces electromagnetic interference and achieves FTC. Stray capacitance controls electromagnetic interference. FTC uses 10 legs and five modules.

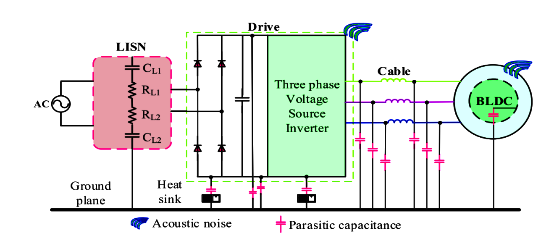

Electromagnetic Interference Management

Defined as electromagnetic signals that disrupt electrical devices, Electro-Magnetic Interference (EMI) interferes with devices such as motors, variable frequency drives, and power converters. These disturbances are undesired within electric circuits. The efficiency and performance of machines are affected by EMI. EMI is categorized as (i) radiated EMI and (ii) conductive EMI. Figure 8 depicts a basic block diagram of the electromagnetic interference algorithm. EMI through conductors causes Conductive EMI between the source and the affected party, while Radiative EMI between the source and the affected party is caused through a wireless medium.

Figure 8. Electromagnetic interfering control

Conductive EMI, often found at lower frequencies, has been classified further into differential mode and common mode. A high source and low impedance are typically found in Common mode EMI sources. Pulsating currents cause Differential mode EMI.

The following techniques are classified for EMI mitigation:

1. EMI filtering and shielding.

2. Random modulation.

3. Chaotic PWM.

Emi Filtering and Shielding Techniques

Transmission lines and power cables use EMI filters to reduce interference. These filters handle frequency content with high input resistance. The fundamental purpose of an EMI filter is to reduce electrical device interference. Active, passive, and hybrid EMI filters exist. LISN stabilizes circuit impedance and assures EMI-free power.

In Chen et al.(22), an effective EMI filter reduced three-phase inverter noise by 40dB µV. Angle modulated switching was used to regulate BLDC motor drive EMI. The EMI filter size was reduced by 50 % and noise was reduced to 10dB µV with this method. Passive filters were designed to manage machine EMI in circuit dv/dt and di/dt spikes are managed by parallel inductors and capacitors. Variations in dv/dt and di/dt increased LC phases.

Random Modulation Techniques

Random modulation changes switching frequency depending on random impulses. Power losses are avoided when the power switch has an appropriate switching frequency. This method's challenges include I increased control algorithm complexity owing to random signal processing and (ii) increased parameter design complexity. Wait-free phase continuous carrier frequency modulation reduced EMI in Zhu et al.(23). WPCFM and digital synthesizer theory enabled fast response and EMI control. EMI content control via spectrum modulation reduced EMI by 5-10dB in Chen et al.(22).

Chaotic PWM Application

Various PWM algorithms create inverter power switch pulses. By using this technology, machine torque ripple, converter dependability, and losses are reduced. EMI generation decreases. The complementary PWM approach was used to reduce three-phase inverter electromagnetic emissions. Bipolar PWM reduced EMI by controlling common-mode emissions.

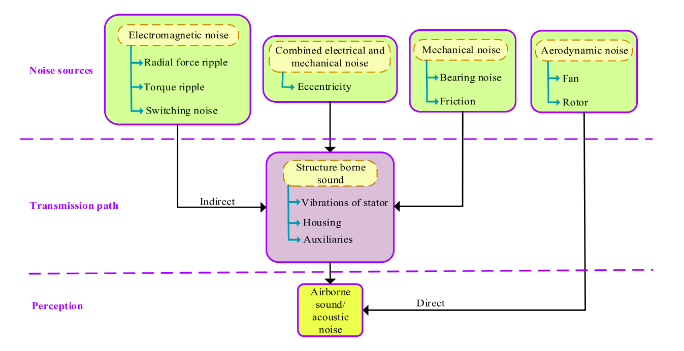

Sound Disturbance Regulation

However, BLDC motors have received limited attention in this regard. Torque ripple, electromagnetic variations, improper flux density distribution between the rotor's permanent magnet and stator slot openings, and harmonic components from non-uniform radial flux distortion cause acoustic noise. As electromagnetic fluctuations and torque ripple in BLDC equipment are regulated, algorithm complexity grows. Noises and vibrations increase EMI and bearing current. Researchers focus on bearing current generation, which might cause motor bearing lock.(23)

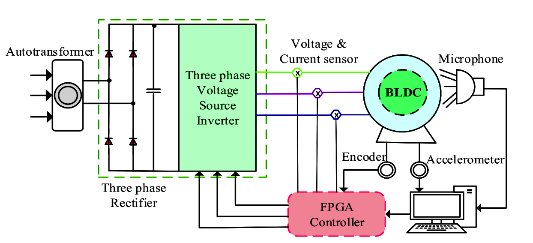

Acoustic noise comes from mechanical disturbance, efficient design noises, electromagnetic fluctuations, misalignment, and machine aerodynamics. Acoustic noise sources and the system's transmission route are shown in figure 9.

Figure 9. Acoustic noise source

A challenging task in acoustic noise regulation lies in diagnosing the primary issue and quantifying the generated noise. Noise quantification employs a combination of microphones and accelerometers paired with embedded controllers. Figure 10 provides a block diagram detailing the methodology for acoustic noise examination.

Figure 10. Acoustic noise control

Scholars have offered design and control algorithm topologies to reduce BLDC motor acoustic noise.(23) Describes real-time field distribution measurements in the permanent magnet's air gap area under different load situations and how to reduce acoustic noise. Slotted stator slots and an integrated permanent magnet rotor worked well. An improved pole magnetic method was used to regulate field harmonics and identify acoustic problems. The torque and flux ripples were predicted as stator currents. Field weakening reduced radial forces in sinusoidal commutated BLDC motors. To solve this, a moving band approach with distinct quadrilateral pieces was used. Rotor optical notches eliminated the third harmonic component in air gap flux density, reducing BLDC motor air gaps and acoustic disturbances. The voltage regulating circuit for a single-phase BLDC machine, utilized in fans, was introduced by Chen et al.(22). The voltage regulator's parallel inductor to series resistance and capacitor reduced noise by 16,1 % compared to older approaches due to fan aerodynamics and variable speed humming.

Origins of Torque Fluctuations

Various factors result in torque ripples, as indicated in Trivedi et al.(24). The sources of these torque ripples are elaborated below and visualized in figure 11.

Figure 11. Torque ripple Sources in BLDC motor

Voltage vector selection in direct torque control depends on flux linkage and torque variables. Disparities are found after processing these details. A hysteresis controller manages these faults with extra reference signals. System flux control manages torque using DTC. DTC is popular due of its verifiable control systems and simplicity. The BLDC motor DTC block diagram is shown in figure 12. In Lad et al.(25), a DTC method with active null vector control is extensively discussed. The suggested method uses a two-level flux and torque hysteresis comparator to establish error signals. To estimate motor torque, torque gradients and switching time are estimated from the inputs. This approach juxtaposes torque and flow responses across vectors.

Figure 12. BLDC motor Direct torque control

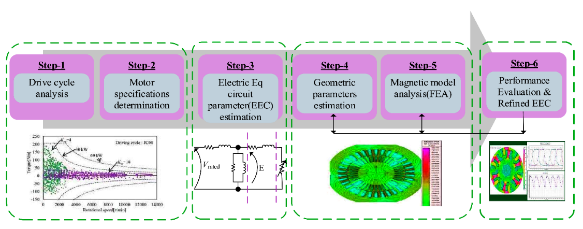

Vectors are guided by a twelve-step direct torque control with a five-level hysteresis controller. This method divides vectors into twelve sections. Every 30 degrees of rotation, the controller receives current and voltage updates. To mitigate torque ripples, the DTC approach maintains a steady current and oscillates the frequency from low to high. Hysteresis controllers regulate stator flux. Induction motor torque ripple reduction is achieved by combining the CSFTC-DTC system with a neutral point clamped multilevel inverter. While the CSFTC maintains a stable switching frequency, the presented approach reduces output torque with its complex control scheme. To achieve a top-performing, cost-effective, and efficient motor, multiple iterations incorporating varied dimensions are conducted to optimize aspects like motor width bottom, tooth width, back iron length, and slot depth. Figure 13 and figure 14 represent the design and procedural steps, respectively, involved in crafting a BLDC motor.

Figure 13. Models of design

Figure 14. Step by step Motor design

MATLAB was used to simulate and test Field-Oriented Control (FOC), Direct Torque Control (DTC), and Intelligent Control. Variations in speed parameters showed significant changes in results for various algorithms.

Comparing FOC, DTC, and Intelligent Control showed that Intelligent Control was more efficient. No dq vector translation, no PWM techniques, no hysteresis controllers for indirect torque control, and low switching frequency make this efficient.

Figures 13 and 14 illustrate FOC control scheme Results for Brushless DC (BLDC) flux and torque at 500 and 1000 rpm. A 15 Nm torque reference was used throughout the simulation Figure 15. Flux and Torque at 500rpm on DTC.

Figure 15. Flux and Torque at 500rpm on DTC

Design Platform for BLDC Motor

High-performance BLDC motor design and development for varied applications is documented by Darba et al.(16). The technology chosen to devise an optimal balance between elements like cost, efficiency, power density, simplicity for manufacturing ease, and more is outlined. This section undertakes the design of a BLDC motor for light electric vehicle uses. Ansys software is used for the 2 kW BLDC motor's design, examination, and refining, following these stages:

1. Sizing of the BLDC motor:

• 2D and 3D simulations.

2. Motor architecture.

3. Electromagnetic aspects.

4. Comprehensive simulations:

• Heat analysis.

• Structural evaluation.

• Modal analysis.

• Computational fluid mechanics evaluation.

5. Dyno testing.

CONCLUSIONS

There appears to be a movement occurring in the automotive industry towards environmentally friendly modes of transportation that produce little pollutants. As a direct consequence of this, increased attention is being paid to electric automobiles as well as the hybrid versions of these cars. BLDC motors have quickly become the motor of choice for electric vehicle (EV) applications due to the fact that they are reliable, simple, and energy efficient. This article presents an analysis of a number of different kinds of BLDC motors, as well as information on their established standards, applications, methods to combat torque fluctuations, and control procedures, as well as insights into BLDC motor design platforms. According to the most recent research:

1. Hub motors, which are a form of outer surface rotor-type BLDC motors, are the type that are most commonly chosen for usage in commercial applications.

2. A hybrid control architecture like predictive torque control with DTC or predictive current control with FOC is being developed. Simplifying direct torque control topologies, vector control multi-level inverter designs, and SVPWM and MLI ideas are important priorities. Intelligent control methods with fewer control vectors and torque ripple reduction controller designs are also prioritized,

3. BLDC motor control drives are utilized so that problems such as fault tolerance, the mitigation of electromagnetic interference, and the reduction of noise may be solved.

4. The outer surface rotor-type motors have gained popularity as a consequence of their minimum cogging torque, which enables them to handle loads better, provide more power, and be more efficient. The reduced cooling requirements for their rotors, which benefit from external air exposure, are another factor that contributes to their allure.

5. Axial-type BLDC motors display improved efficiency and torque when compared to other types of electric vehicle (EV) motors. This is the case despite the fact that BLDC motors demonstrate stronger torque fluctuations at slower speeds and decreased ones at higher velocities. The Hub motor is a good option for electric vehicles due to its capacity to adapt as well as its small size.

6. This work outlines design considerations and FEA evaluations for both inner rotor and outer rotor BLDC motors.

7. The intelligent controller outperforms its counterparts in decreasing torque fluctuations.

8. This paper outlines the various control techniques for BLDC motors. The effectiveness of the outer surface rotor-type BLDC motor was validated by the results of the simulation, a fact that was further supported by the data obtained from the hardware. In conclusion, the existing difficulties in BLDC motor current modulation approaches as well as the possibilities for further study are outlined for upcoming researchers.

REFERENCES

1. H.-W. Kim, K.-T. Kim, Y.-S. Jo, and J. Hur, ‘‘Optimization methods of torque density for developing the neodymium free SPOKE-type BLDCmotor,’’ IEEE Trans. Magn., vol. 49, no. 5, pp. 2173–2176, May 2013, doi: 10.1109/TMAG.2013.2237890.

2. J. Shao, ‘‘An improved microcontroller-based sensor less brushless DC (BLDC) motor drive for automotive applications,’’ IEEE Trans. Ind. Appl., vol. 42, no. 5, pp. 1216–1221, Sep. 2006.

3. J. Shao, ‘‘An improved microcontroller-based sensorless brushless DC (BLDC) motor drive for automotive applications,’’ in Proc. 40th IAS Annu. Meeting. Conf. Rec. Ind. Appl. Conf., Oct. 2005, pp. 2512–2517.

4. C. L. Xia, Permanent Magnet Brushless DC Motor Drives and Controls. Singapore: Wiley, 2012.

5. K. P. Kumar, ‘‘Modeling of a commercial BLDC motor and control using GA- controller for a BLDC propulsion application for hybrid electric vehicle,’’ Int. J. Psychosocial Rehabil., vol. 23, no. 4, pp. 1604–1613, Dec. 2019.

6. A. Senthilnathan and P. Palanivel, ‘‘Fuzzy logic controller based zeta converter for BLDC motor,’’ J. Adv. Res. Dyn. Control Syst., vol. 12, no. 7, pp. 125–133, Jul. 2020.

7. H.-J. Kim, ‘‘BLDC motors for robot vacuum cleaners,’’ Trans. Korean Inst. Electr. Eng., vol. 60, no. 4, pp. 172–174, Dec. 2011.

8. J. W. K. K. Jayasundara and R. Munasinghe, ‘‘Software design tool for optimum axial flux BLDC motors,’’ in Proc. Int. Conf. Ind. Inf. Syst. (ICIIS), Dec. 2009, pp. 526–531.

9. G. Sotyaramadhani, A. Wikarta, and M. N. Yuniarto, ‘‘Different approach of fuzzy logic algorithm implementation for increasing performance of axial BLDC motor,’’ in Proc. AIP Conf., 2018, Art. no. 060010.

10. S. De, M. Rajne, S. Poosapati, C. Patel, and K. Gopakumar, ‘‘Low inductance axial flux BLDC motor drive for more electric aircraft,’’ in Proc. Aerosp. Conf., Mar. 2011, pp. 1–11, doi: 10.1109/AERO.2011.5747464.

11. G. D. Donato, G. Scelba, M. Pulvirenti, G. Scarcella, and F. G. Capponi, ‘‘Low-cost, high-resolution, fault-robust position and speed estimation for PMSM drives operating in safety-critical systems,’’ IEEE Trans. Power Electron., vol. 34, no. 1, pp. 550–564, Jan. 2019.

12. Y. Ming and J.-X. Shen, ‘‘Research on conducted EMI and vibration characteristics of PM BLDC motors with different stator structures,’’ in Proc. Int. Conf. Electr. Mach. Syst., Aug. 2011, pp. 1–6, doi: 10.1109/ICEMS.2011.6073454.

13. A. Tashakori and M. Ektesabi, ‘‘A simple fault tolerant control system for Hall effect sensors failure of BLDC motor,’’ in Proc. IEEE 8th Conf. Ind. Electron. Appl. (ICIEA), Jun. 2013, pp. 1011–1016.

14. M. Perotti, ‘‘On the influence of the load parasitics on the CM conducted EMI of BLDC motor drives,’’ in Proc. IEEE Int. Conf. Environ. Electr. Eng. Ind. Commercial Power Syst. Eur. (EEEIC/I&CPS Eur.), Jun. 2020, pp. 1–6, doi: 10.1109/EEEIC/ICPSEurope49358. 2020.9160663.

15. G. Buja, M. Bertoluzzo, and R. K. Keshri, ‘‘Torque ripple-free operation of PM BLDC drives with petal-wave current supply,’’ IEEE Trans. Ind. Electron., vol. 62, no. 7, pp. 4034–4043, Jul. 2015, doi: 10.1109/TIE.2014.2385034.

16. A. Darba, F. D. Belie, P. D’haese, and J. A. Melkebeek, ‘‘Improved dynamic behavior in BLDC drives using model predictive speed and current control,’’ IEEE Trans. Ind. Electron., vol. 63, no. 2, pp. 728–740, Feb. 2016, doi: 10.1109/TIE.2015.2477262.

17. T. Yazdan, W. Zhao, T. A. Lipo, and B.-I. Kwon, ‘‘A novel technique for two-phase BLDC motor to avoid demagnetization,’’ IEEE Trans. Magn., vol. 52, no. 7, pp. 1–4, Jul. 2016, doi: 10.1109/TMAG.2016.2521874. .

18. J. Shao, ‘‘An improved microcontroller-based sensor less brushless DC (BLDC) motor drive for automotive applications,’’ IEEE Trans. Ind. Appl., vol. 42, no. 5, pp. 1216–1221, Sep./Oct. 2006.

19. I.-S. Jung, H.-G. Sung, Y.-D. Chun, and J.-H. Borm, ‘‘Magnetization modeling of a bonded magnet for performance calculation of inner-rotor type BLDC motor,’’ IEEE Trans. Magn., vol. 37, no. 4, pp. 2810–2813, Jul. 2001, doi: 10.1109/20.951314.

20. T. A. Anuja and M. A. N. Doss, ‘‘Reduction of cogging torque in surface mounted permanent magnet brushless DC motor by adapting rotor magnetic displacement,’’ Energies, vol. 14, no. 10, p. 2861, May 2021, doi: 10.3390/en14102861.

21. J. Sun, Y. Chai, C. Su, Z. Zhu, and X. Luo, ‘‘BLDC motor speed control system fault diagnosis based on LRGF neural network and adaptive lifting scheme,’’ Appl. Soft Comput., vol. 14, pp. 609–622, Jan. 2014.

22. P.-S. Chen and Y.-S. Lai, ‘‘Effective EMI filter design method for threephase inverter based upon software noise separation,’’ IEEE Trans. Power Electron., vol. 25, no. 11, pp. 2797–2806, Nov. 2010.

23. Z. Q. Zhu and D. Howe, ‘‘Instantaneous magnetic field distribution in brushless permanent magnet DC motors, part II: Armaturereaction field,’’ IEEE Trans. Magn., vol. 29, no. 1, pp. 136–142, Jan. 1993.

24. M. B. Trivedi and J. J. Patel, ‘‘A DSC—Based field oriented control of SPMSM to mitigate practical difficulties with low resolution sxIncremental encoder,’’ in Proc. Int. Conf. Comput. Power, Energy, Inf. Commun. (ICCPEIC), Apr. 2014, pp. 455–461.

25. C. K. Lad and R. Chudaman, ‘‘Simple overlap angle control strategy for commutation torque ripple minimisation in BLDC motor drive,’’ IET Electr. Power Appl., vol. 12, no. 6, pp. 797–807, Jul.202

FINANCING

There is no specific funding to support this research.

CONFLICT OF INTEREST

All authors reviewed the results, approved the final version of the manuscript and agreed to publish it.

AUTHORSHIP CONTRIBUTION

Conceptualization: Suhair Akram, Mohanned Aljanabi.

Data curation: Suhair Akram, Mohanned Aljanabi.

Formal analysis: Suhair Akram, Mohanned Aljanabi.

Research: Suhair Akram, Mohanned Aljanabi.

Methodology: Suhair Akram, Mohanned Aljanabi.

Drafting - original draft: Suhair Akram, Mohanned Aljanabi.

Writing - proofreading and editing: Suhair Akram, Mohanned Aljanabi.