Category: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

Developing a Novel Cold Bitumen Emulsion Mixes by Adding Geopolymer

Desarrollo de nuevas mezclas de emulsión bituminosa en frío mediante la adición de geopolímeros

Ahmed Mahdi Ibrahim1 *, Taher M. Ahmed2 *, Thamir Y. Ahmed3 *

1Researcher at the Department of Civil Engineering, College of Engineering, University of Anbar, Anbar, Iraq.

2Ramadi Municipality Directorate, Anbar, Iraq.

3Department of Civil Engineering, College of Engineering, University of Anbar, Anbar, Iraq.

Cite as: Mahdi Ibrahim A, Ahmed TM, Ahmed TY. Developing a Novel Cold Bitumen Emulsion Mixes by Adding Geopolymer. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:864. https://doi.org/10.56294/sctconf2024864

Submitted: 03-02-2024 Revised: 16-04-2024 Accepted: 09-06-2024 Published: 10-06-2024

Editor: Dr.

William Castillo-González ![]()

Note: Paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

Cold bituminous emulsion mixtures (CBEMs), which are less costly, need less energy, and are more environmentally friendly, maybe can take the place of hot mix asphalt (HMA) in the future. It is known, that these mixtures have a very low initial strength, requiring longer curing times and more susceptibility to moisture damage. Geopolymer is often used in the fields of concrete and soil improvement performance. It has not been used in the field of asphalt mixtures; so, this study can be considered as the first time of using it. This study tried to make a new CBEM by incorporating the Geopolymer into the mix to improve its initial performance and enhance early strength. Geopolymer was created inside CBEM by activating the fly ash using an alkali solution. Three percentages of fly ash (1, 3, and 5 %) were used for creating Geopolymer; and different curing periods (3, 7, and 14 days) were also used. Marshall stability and Indirect Tensile Strength tests were conducted to assess the mechanical properties of mixtures. The results showed that Geopolymer can be a promising material for creating cold mixes with a better initial strength compared to traditional cold mixes. Comparing CBEMs with (5 % FA + 0 % CF) to control CBEMs, the increase with MS was approximately (32 % at 3 days, 43 % at 7 days, and 37 % at 14 days). The performance of cold mixes was enhanced by the addition of Geopolymer with different FA contents and curing times when compared to control CBEMs. This improvement was particularly noticeable at longer curing times and higher fly ash contents.

Keywords: Cold Bituminous Emulsion Mixtures; Marshall Stability; Indirect Tensile; Fly Ash; Geopolymer.

RESUMEN

Las mezclas de emulsión bituminosa en frío (CBEM), que son menos costosas, necesitan menos energía y son más respetuosas con el medio ambiente, quizá puedan sustituir a las mezclas asfálticas en caliente (HMA) en el futuro. Se sabe que estas mezclas tienen una resistencia inicial muy baja, requieren tiempos de curado más largos y son más susceptibles a los daños causados por la humedad. El geopolímero se utiliza a menudo en el campo del hormigón y de la mejora del suelo. No se ha utilizado en el campo de las mezclas asfálticas, por lo que este estudio puede considerarse como la primera vez que se utiliza. Este estudio trató de hacer un nuevo CBEM mediante la incorporación del Geopolímero en la mezcla para mejorar su rendimiento inicial y mejorar la resistencia temprana. El geopolímero se creó dentro del CBEM activando las cenizas volantes mediante una solución alcalina. Se utilizaron tres porcentajes de cenizas volantes (1, 3 y 5 %) para crear el Geopolímero; y también se utilizaron diferentes periodos de curado (3, 7 y 14 días). Se realizaron ensayos de estabilidad Marshall y de resistencia indirecta a la tracción para evaluar las propiedades mecánicas de las mezclas. Los resultados mostraron que el Geopolímero puede ser un material prometedor para crear mezclas en frío con una mejor resistencia inicial en comparación con las mezclas en frío tradicionales. Comparando CBEMs con (5 % FA + 0 % CF) con CBEMs de control, el aumento con MS fue aproximadamente (32 % a los 3 días, 43 % a los 7 días, y 37 % a los 14 días). El rendimiento de las mezclas en frío mejoró con la adición de Geopolímero con diferentes contenidos de AF y tiempos de curado en comparación con los CBEM de control. Esta mejora fue particularmente notable con tiempos de curado más largos y mayores contenidos de cenizas volantes.

Palabras clave: Mezclas Bituminosas en Emulsión en Frío; Estabilidad Marshall; Tracción Indirecta; Cenizas Volantes; Geopolímero.

INTRODUCTION

Cold Bituminous Emulsion Mixtures (CBEMs) are often produced at ambient temperatures under various climatic circumstances without heating for both aggregates and bitumen, it has a wide range of production temperatures.(1)

CBEM uses less energy during manufacture and application than Hot Mix Asphalt HMA since it does not require heating. CBEMs are frequently made using recycled materials, such as reclaimed asphalt pavement (RAP). Using recycled resources in CBEM production reduces the demand for virgin aggregates and asphalt binders, lowering the environmental effect.

The advantages of CBEM’s sustainability make it a potential paving option for the development of sustainable infrastructure.(2)

Even though CBEM procedures are superior to HMA in terms of ecological, production, and economic goals, they do have certain drawbacks. These include poor early strength, large void ratios, and a longer curing period needed to reach full strength.(3)

Numerous parameters, such as the grade and features of the binders, the amount of void in the mixtures, the curing period, the aggregate characteristics, and additives were considered to show the influence on the mechanical properties of bituminous pavement, stiffness modulus, permanent deformation, and fatigue resistance.(4)

Attempts to improve cold mixes’ mechanical properties have been investigated by several researchers such as H Al Nageim et al. (2012) utilized a percentage of FA, ranging from 0 % to 5,5 % of the aggregate weight, to replace filler in the mix. The uniaxial compressive cyclic test and the indirect tensile stiffness modulus were used to determine the improvement in performance properties; the water sensitivity test was conducted concurrently with an investigation into the new mixes’ durability.(5)

Abbas Al-Hdabi et al. (2014) examined methods for enhancing cold-rolled asphalt’s (CRA) mechanical properties and water sensitivity by substituting traditional filler with waste or by-product materials. To accomplish this, silica fume (SF) was added as an additive in the range of 0–3 % by the total mass of the aggregate, and waste fly ash (WFA) was utilized as a substitute for traditional filler in the range of 0-6 % by the total mass of the aggregate.(6) Ahmed I. Nassar et al. (2016) investigated how adding binary and ternary blended fillers (TBF and BBF) affects the microstructure and engineering characteristics of CAEMs. The BBF was made of ground granulated blast furnace slag (GGBS), fly ash (FA), and ordinary Portland cement (OPC); silica fume (SF) was then added to the BBF to create TBF.(7)

Anmar Dulaimi et al. (2017) created a novel cold asphalt concrete that cures quickly and is safe for the environment for use in binder courses (CACB). includes fluid catalytic cracking catalyst residue (FC3R), waste, high calcium fly ash (HCFA), and a binary blended cementitious filler (BBCF) activated by a waste alkaline NaOH solution.(8)

Abdulrahman Hamid et al. (2020) studied the rheological behavior and performance grading of the asphalt modified with Geopolymer at varying temperatures by conducting many laboratory experiments at concentrations of 3 %, 6 %, and 9 %. This experiment also assessed the effect of varying curing times on the performance of Geopolymer. Environmental scanning electron microscopy (ESEM) was then used to examine the microstructure of the modified asphalt binder and base.(9)

Teerasak Yaowarat et al. (2021) created marginal crushed rock (CR) stabilized with fly ash-asphalt emulsion (FA-AE) as a sustainable pavement base material. A mixture of sodium hydroxide (NaOH) and sodium silicate hydrate (Na2SiO3) at Na2SiO3: NaOH = 50:50 and NaOH concentration = 5 M was utilized as a liquid alkaline activator. In this study, tests for unconfined compressive strength (UCS), indirect tensile strength (ITS), flexural strength (FS), indirect tensile resilient modulus (IT Mr), and indirect tensile fatigue life (ITFL) were used to examine the mechanical properties of FA-AE stabilized CR.(10)

The main aims of this study are to examine the impact of the incorporation of the Geopolymer into CBEMs and create an approach or procedure for adding Geopolymer to CMA as an additive enhancing early strength and accelerating the cure time by incorporating the Geopolymer material.

Materials

In this study, all materials are supplied from the local markets in Iraq.

Aggregate

The aggregates, i.e. coarse and fine aggregates, were supplied locally from the Thumail quarry about 60 km west of Ramadi City in Anbar province. Physical properties are summarized in table 1 which are tested according to the American Society for Testing Materials. Table 2 lists the selected gradation and specification limitations of the base course by General Specifications for Roads and Bridges S.O.R.B.

|

Table 1. Characteristics of fine, coarse aggregate and mineral filler(11,12,13) |

||

|

Material |

Property |

Value |

|

Coarse Aggregate |

Bulk specific gravity |

2,573 |

|

Apparent specific gravity |

2,647 |

|

|

Water absorption, % |

1,089 |

|

|

Fine Aggregate |

Bulk specific gravity |

2,424 |

|

Apparent specific gravity |

2,655 |

|

|

Water absorption, % |

3,6 |

|

|

Mineral Filler |

Particle specific gravity |

2,706 |

|

Table 2. Selected base course gradation according to (SORB/ R9)(14) |

||

|

Sieve opening (mm) |

Limits of passing % |

Mid of Passing % |

|

37,5 |

100 |

|

|

25,4 |

90-100 |

95 |

|

19 |

76-90 |

83 |

|

12,5 |

56-80 |

68 |

|

9,5 |

48-74 |

61 |

|

4,75 |

29-59 |

44 |

|

2,36 |

19-45 |

32 |

|

0,3 |

5-17 |

11 |

|

0,075 |

2-8 |

5 |

Fly Ash (FA)

Fly ash is typically seen as a waste product that results from the combustion of coal. Fly ash comes in a variety of forms, including Class F and Class C, which are produced by burning black coal and brown coal, respectively.(15) In this study, Fly Ash type (F) was provided and classified according to (ASTM) C618. The FA as a filler was used at different percentages with ratios, (Fly ash, Limestone dust): (0,5), (1,4), (3,2), and (5,0) % of the total weight aggregate (1200 gm), the properties are shown in table 3.

|

Table 3. Analysis of XRF for FA(16) |

|

|

Compound |

Percentage % |

|

SiO2 |

38,5 |

|

Al2O3 |

28,8 |

|

Fe2O3 |

3,75 |

|

CaO |

21,5 |

|

MgO |

1,1 |

|

SO3 |

0,5 |

|

Na2O3 |

0,06 |

|

K2O |

0,5 |

|

Cl |

0,002 |

|

L.O. I |

2,18 |

Conventional Fille

The traditional filler, i.e. limestone dust (LD), was used in this study. For preparing CMA, LD was used in four percentages (Fly ash, Limestone dust): (0,5), (1,4), (3,2), and (5,0) % by total weight of aggregate.

Emulsified Asphalt (EA)

In this study, all CBEM specimens are made by using cationic slow setting type CSS-1 EA. Table 4 summarizes the properties of used EA according to AASHTO M208-2009.

|

Table 4. Properties of EA (17) |

|

|

Property |

Value |

|

Residue by evaporation, % |

58 |

|

Relative Density at. 15 ºC, [g/cm3] |

1,105 |

|

Appearance. |

Dark brown to black liquid |

|

Residual bitumen penetration, 1/10 [mm] |

45 |

|

Particle charge |

Positive |

Alkali Solution

Alkali solution was prepared by mixing sodium hydroxide solution (NaOH) and sodium silicate solution (Na2SiO3). Alkali solution was prepared as an activator for Flay Ash to create a Geopolymer. The properties of NaOH and Na2SiO3 are shown in Table 5 below. An important role for alkali solutions in producing cold asphalt mixes is using pre-watering for aggregates instead of using water, as detailed below.

|

Table 5. Properties of compositions of alkali solution |

|

|

Property |

Value |

|

NaOH |

|

|

Purity, % |

98 |

|

Na2SiO3 |

|

|

H2O, % |

25,38 |

|

NaSiO, % |

74,61 |

Experimental program

Cold mix asphalt (CMA) design

According to the Asphalt Institute (MS14-1989) procedure,(18) the following steps have been adopted for the design of the cold mix:

1. Evaluate Initial Residual Asphalt Content (IRAC)

The initial residual asphalt content (P) for CBEMs was determined using the empirical equation developed by Asphalt Institute as shown in equation 1.

P = 0,7(0,05A + 0,1B + 0,5C) (1)

Where:

P = is the percentage of emulsified asphalt in weight, depending on the weight of the dry aggregate،

A = Percentage of material retained on sieve No. 4 (size 4,75 mm).

B = Percentage of aggregate passing sieve No. 4 (size 4,75 mm) and retained on sieve No. 200 (size 0,075 mm).

C = Percentage of aggregate passing sieve No. 200 (size 0,075 mm).

2. Evaluation of Initial Emulsion Content (IEC)

IEC represents the total emulsified asphalt with all components (water, asphalt, and emulsified agent), this is calculated using equation 2:

IEC = P/X (2)

Where: X= is the residual asphalt percentage in the emulsion. Which is determined by heating the emulsion until all the water has evaporated according to ASTM D-244.(19)

3. Determination of Optimum Pre-Watering Content (OPWC)

According to MS-14, cold mix design requires extra water must be mixed with aggregate before adding emulsion, this amount of water is called pre-watering contents which helps to spread the emulsion over all the aggregate to give a better coating. In this regard, different water content, (3 – 6) % by mass of aggregate, were mixed with aggregate for a minute and then IEC was added and mixed for two minutes. Based on a visual inspection the water contents that give better coating, i.e. more than 50 % of aggregate is coated and the mixture is neither stiff nor sloppy, was selected to be OPWC.

4. Determination of Optimum Residual Asphalt Content (ORAC)

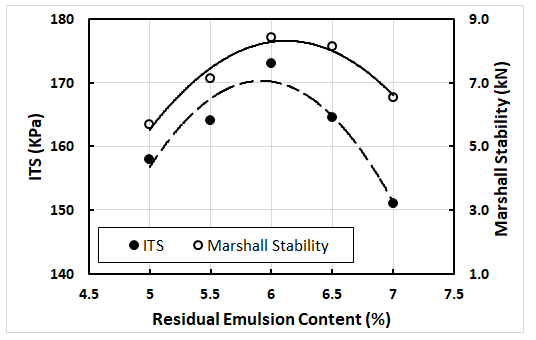

The selected OPWC from the previous step was fixed and then different emulsified asphalt was used (two percentages over and two percentages under IEC) for fabricating a set of cylindrical specimens, i.e. more details below. Then the fabricated specimens were evaluated using the Marshall test method to determine the Marshal Stability (MS) and Indirect Tensile strength (ITS) tests to determine the optimum emulsion contents; where the emulsion contents are the average of the content which gives the highest MS and ITS. Figure 1 shows the results of MS and ITS, it is clear there are no significant differences between both tests in evaluating the ORAC. Table 6 summarizes the mix design parameters.

Figure 1. Determination of Optimum Residual Asphalt Content (ORAC) in terms of Marshall stability and ITS

|

Table 6. Mix design parameters |

||

|

No. |

Properties |

Value (%) |

|

1 |

Initial residual asphalt content (IRAC) |

6,02 |

|

2 |

Residual asphalt contest (X) |

58 |

|

3 |

Initial emulsion content (IEC) |

10,38 |

|

4 |

Optimum pre-watering content (OPWC) |

3 |

|

5 |

Optimum residual asphalt content (ORAC) |

5,90 |

Preparation of Cold Bituminous Emulsion Mixtures (CBEMs)

The mixing method was used to blend CAEM specimens. With pre-wetting water content (3 % of the aggregate mass), the filler and aggregate materials were slowly mixed for one minute. During the following minute of mixing at the same speed, asphalt emulsion was gradually added. Three minutes of mixing were completed by repeating this procedure at high speed for an additional minute. The mixture was then manually poured into a clean mold, and then it was compacted by Marshall hammer 75 times blows on each side. Later, the molds with samples were left in the lab at room temperature for 24 hours to be extracted the next day from the mold and left for curing at room temperature.

Preparation of Geopolymer (GP)

In this study, Geopolymer consists of an alkali solution (NaOH solution [4M] and Na2SiO3) and Fly Ash type F. CBEMs containing FA at concentrations of 1, 3, and 5 % by total aggregate weight as filler. The specimens were prepared and evaluated to determine Marshall stability and Tensile Strength Ratio (TSR).

Testing Program

Marshall stability

The stability of (CBEM) specimens is tested using the same Marshall stability apparatus as it is used to test the stability of hot mixes according to ASTM D6927-15. Reminder, the controlled mixes, for accelerating the curing, were cured in the oven for 72 hours at 40°C. While, other samples were left at room temperature for curing times 3, 7, and 14 days and then were tested in Marshall apparatus at 60°C after leaving in the oven at 60°C for 120 min for conditioning.(20)

Tensile Strength Ratio (TSR) test

In this test method, the asphalt concrete compression combinations’ resistance to damage from moisture was appreciated. In this test, the sample is loaded at a constant rate of deformation of 2 inches per minute or 50 millimeters per minute of vertical ram movement of the sample, and this loading rate is maintained until failure using the Marshall apparatus. In this study, two cases are tested:

1. Unconditioned, in this case, the samples are evaluated in a water bath at 25 °C for an hour.

2. Conditioned, in this case, the samples can be examined in a water bath at 25 °C for 24 hours.

For both cases, indirect tensile strength is calculated according to equation 3 .

ITS=2P/πdt (3)

Where ITS = Indirect tensile strength [MPa]

P = Load [N], d= Diameter of specimen [mm],

t = Thickness of specimen [mm].

TSR=ITSc/ITSu (4)

Where, ITSc = the indirect tensile strength (Conditioned) [KPa].

ITSu = the indirect tensile strength (Unconditioned) [KPa].

The tensile strength ratio (TSR) was assessed in this study by contrasting it with alternative techniques for assessing asphalt mixtures’ moisture sensitivity.(21) Examining the mechanical properties of the TSR parameter and how it relates to other factors, including Marshall stability (MS) for compacted asphalt mixes, is one of the main goals of this work.

RESULTS AND DISCUSSION

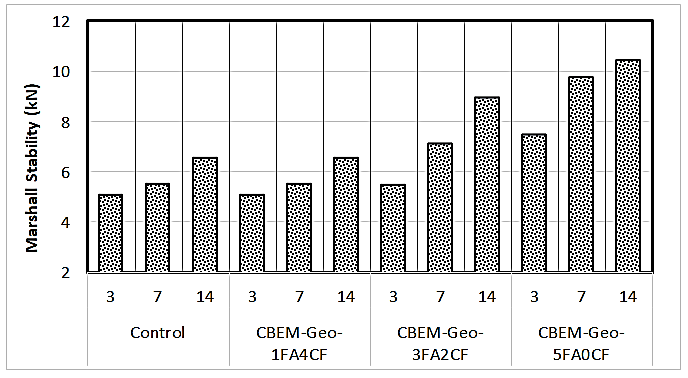

Effect of curing time and Geopolymer content on Marshall stability Test for CBEMs

The Marshall apparatus and procedure were used in this test to evaluate the stability (maximum shear strength in [KN]) at peak strength.(22) The influence of adding Geopolymer with different concentrations of FA with different curing times is shown in figure 2.

Figure 2. Effect of Geopolymer on Marshall Stability

The MS increases as curing time progresses irrespective of mix type, this may be attributed to the evaporating of water accelerating in the breaking point of emulsion which leads to improvement in the adhesive bond between emulsion and aggregate. Regarding Geopolymer with CBEM, increasing the replacement of fly ash by traditional filler (limestone dust) improved the MS irrespective of curing time except at fly ash 1 % where there are no significant differences with the control mix as shown in figure 2. This point is crucial where it refers to the role and activity of Geopolymer with emulsified asphalt. On the other hand, as the fly ash, the initial strength of CBEM accelerated and this may be attributed to the viability of alkali solution and flay ash getting a completing chemical reaction to produce hydrated materials which improves the strength of CBEM especially when fly ash is 3 and 5 %. It also shows that CBEMs with (5 % FA + 0 % CF) have increased with MS by about (32 %) at 3 days, (43 %) at 7 days, and (37 %) at 14 days compared to control CBEMs. Overall, improving MS means improving the stiffness of mixes and, consequently better performance against permanent deformation or rutting.(23)

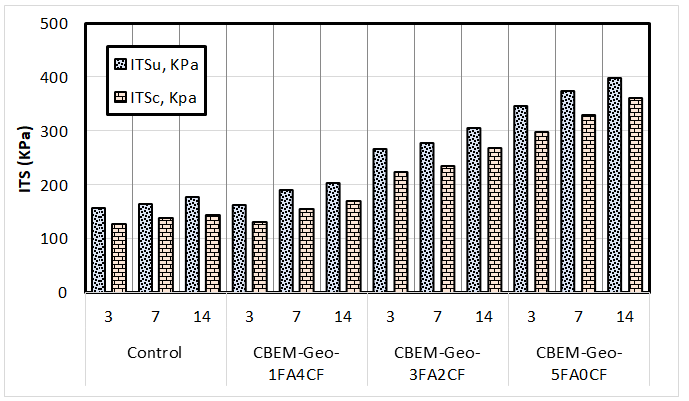

Effect of curing time and Geopolymer content on ITS for CBEMs

In evaluating the performance of CBEMs, the Indirect Tensile Strength (ITS) test is essential for this purpose.(24) It is known, that the ITS test can be used for evaluating two main performance properties: cracking resistance and moisture damage using TSR. Figure 3 displays the effect of Geopolymer on ITS for unconditional and condition states at different curing times.

Figure 3. Effect of Geopolymer on Indirect Tensile Strength (ITS)

The same trend as in MS, as curing time progresses, ITS increases for both conditioned and unconditioned state, this also confirms the effect of curing time on the performance of CBEMs. Also, Geopolymer has a significant effect on the performance of mixes as shown by the improvement in the ITS for both conditioned and unconditioned states; this also confirms the feasibility and activity of Geopolymer incorporated within CBEMs regardless of the fly ash ratios. These results also emphasize the improvements in CBEMs against cracking which attributed to the role of Geopolymer which is more pronounced at fly ash 5 %, maybe due to the full chemical reaction between alkali solution and fly ash.

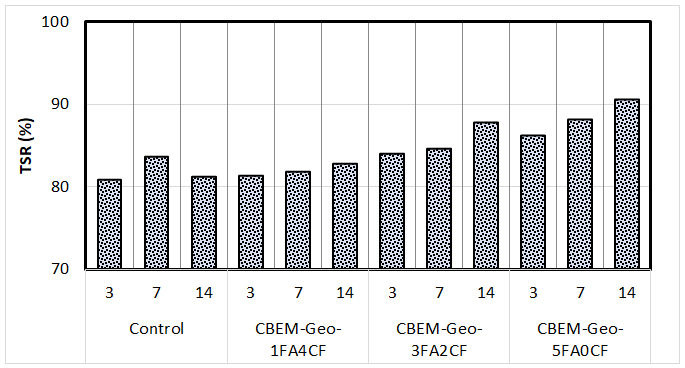

On the other hand, the moisture damage is noticeable from figure 4 in terms of TSR; however, all mixes displayed acceptable performance, i.e. TSR greater than 80 %, Geopolymer showed better resistance against moisture damage; where all mixes have TSR higher than control mix except at 7 days where it is the higher. Besides, curing time has also a great effect on the development of TSR for all CBEMs with Geopolymer, this also can be attributed to the hydration effect for fly ash with an alkali solution to produce Geopolymer which improves the strength of mixes. Also, Geopolymer at fly ash 5 % was the better performance regardless of the curing time.

Figure 4. Effect of Geopolymer on Tensile Strength Ratio (TSR)

CONCLUSION

The main aim of this study was to determine the feasibility of producing Geopolymer base fly ash and alkali solution within cold bitumen emulsion mixtures. Based on the findings of this study, the following conclusion can be drawn:

3. Geopolymer can be produced within the cold asphalt mixes using alkali solution as pre-watering and fly ash as a filler. Where alkali solution acts as an activator for fly ash to create Geopolymer.

4. In comparison to control CBEMs, the addition of Geopolymer with varying FA contents and different curing times improved the performance of cold mixes in terms of Marshall stability and Indirect Tensile Strength; this improvement was more pronounced at longer curing time and high fly ash contents giving high possibility to fully chemical reaction and hydration for fly ash with alkali solution.

5. Geopolymer significantly improved cold mixes against rutting, cracking, and moisture damage.

6. Further works are required to be made for evaluating the performance of cold mix asphalt with Geopolymer against fatigue performance, permanent deformation, and others, also need to complete the comparison with HMA and anionic CMA.

REFERENCES

1. H. K. Shanbara, A. Shubbar, F. Ruddock, et al., “Characterizing the rutting behavior of reinforced cold mix asphalt with natural and synthetic fibers using finite element analysis.” pp. 221-227.

2. Z. Al-Hashimi, S. Al-Busaltan, and B. Al-Abbas, “Advancements and Challenges in the Use of Cold Mix Asphalt for Sustainable and Cost-Effective Pavement Solutions.” p. 03006.

3. H. K. Shanbara, A. Dulaimi, T. Al-Mansoori, et al., “The future of eco-friendly cold mix asphalt,” Renewable and Sustainable Energy Reviews, vol. 149, pp. 111318, 2021.

4. I. N. Thanaya, “Improving the performance of cold bituminous emulsion mixtures (CBEMs): incorporating waste,” 01/01, 2003.

5. H. Al Nageim, S. F. Al-Busaltan, W. Atherton, et al., “A comparative study for improving the mechanical properties of cold bituminous emulsion mixtures with cement and waste materials,” Construction and building materials, vol. 36, pp. 743-748, 2012.

6. A. Al-Hdabi, H. Al Nageim, F. Ruddock et al., “Development of sustainable cold rolled surface course asphalt mixtures using waste fly ash and silica fume,” Journal of Materials in civil engineering, vol. 26, no. 3, pp. 536-543, 2014.

7. A. I. Nassar, M. K. Mohammed, N. Thom, et al., “Mechanical, durability and microstructure properties of Cold Asphalt Emulsion Mixtures with different types of filler,” Construction and Building Materials, vol. 114, pp. 352-363, 2016.

8. A. Dulaimi, H. Al Nageim, F. Ruddock et al., “High-performance cold asphalt concrete mixture for binder course using alkali-activated binary blended cementitious filler,” Construction and Building Materials, vol. 141, pp. 160-170, 2017.

9. A. Hamid, H. Alfaidi, H. Baaj et al., “Evaluating fly ash-based geopolymers as a modifier for asphalt binders,” Advances in Materials Science and Engineering, vol. 2020, pp. 1-11, 2020.

10. T. Yaowarat, W. Sudsaynate, S. Horpibulsuk, et al., “Mechanical properties of fly ash–asphalt emulsion geopolymer stabilized crushed rock for Sustainable pavement base,” Journal of Materials in Civil Engineering, vol. 33, no. 9, pp. 04021220, 2021.

11. A. S. f. T. M. ASTM, “C127,” Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate, C127-2015.

12. A. S. f. T. M. ASTM, “C128,” Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate, C128-07.

13. ASTM, “Standard Specification for Mineral Filler For Bituminous Paving Mixtures,” D242-1995.

14. General specification for road and bridges, SORB 2003.

15. N. Gamage, K. Liyanage, S. Fragomeni, et al., “Overview of different types of fly ash and their use as a building and construction material,” 2011.

16. ASTM, “Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete,” C618-2012.

17. A. A. o. S. H. a. T. O. AASHTO, “M208,” Standard Specification for Cationic Emulsified Asphalt, M208-2009.

18. A. Institute, Asphalt Cold Mix Manual, MS14-1989.

19. A. S. f. T. M. ASTM, “D 244,” Standard Test Methods and Practices for Emulsified Asphalts, D 244 – 2000.

20. ASTM, “Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures,” D6927-15.

21. T. C. Do, V. P. Tran, H. J. Lee, et al., “Mechanical characteristics of tensile strength ratio method compared to other parameters used for moisture susceptibility evaluation of asphalt mixtures,” Journal of Traffic and Transportation Engineering (English Edition), vol. 6, no. 6, pp. 621-630, 2019.

22. H. H. Zghair, “Properties of Cationic Emulsified Asphalt Paving Mixtures,” University of Technology, 2012.

23. M. Arabani, S. A. Tahami, and M. Taghipoor, “Laboratory investigation of hot mix asphalt containing waste materials,” Road Materials and Pavement Design, vol. 18, no. 3, pp. 713-729, 2017.

24. A. A. Shala, and A. Al-Hdabi, “Dense Grade Surface Course Cold Asphalt Emulsion Mixture Properties Containing Cement and Wheat Straw Ash (WSA).” p. 03029.

FINANCING

None.

CONFLICT OF INTEREST

None.

AUTHORSHIP CONTRIBUTION

Conceptualization: Ahmed Mahdi Ibrahim, Taher M. Ahmed, Thamir Y. Ahmed.

Research: Ahmed Mahdi Ibrahim, Taher M. Ahmed, Thamir Y. Ahmed.

Writing - original draft: Ahmed Mahdi Ibrahim, Taher M. Ahmed, Thamir Y. Ahmed.

Writing - revision and editing: Ahmed Mahdi Ibrahim, Taher M. Ahmed, Thamir Y. Ahmed.