Category: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

ANOVA statistical analysis for determining the optimum contain of waste powders in concrete

Análisis estadístico ANOVA para determinar el contenido óptimo de residuos en polvo en el hormigón

Sheelan Mahmoud Hama1 *, Husam K. K. Al-Ani1 *, Ibrahim H Alfahdawi2 *

1Civil engineering department, University of Anbar. Ramadi, Iraq.

2Renewable Energy Research Center, University of Anbar. Ramadi, Iraq.

Cite as: Mahmoud Hama S, K. Al-Ani HK, H Alfahdawi I. ANOVA statistical analysis for determining the optimum contain of waste powders in concrete. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:852. https://doi.org/10.56294/sctconf2024852

Submitted: 01-02-2024 Revised: 16-04-2024 Accepted: 04-06-2024 Published: 05-06-2024

Editor: Dr.

William Castillo-González ![]()

Note: paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

Reusing and recycling waste are efficient ways to reduce waste production while dealing with associated environmental issues. The applications still have a lot of opportunity for improvement, though. This academic article discusses recycled glass and eggshell waste used in construction. The impact of these wastes on specific mechanical characteristics was examined. These wastes have been used as powder and partially substituted for cement in concrete. From the results, it was found that utilizing 10 % glass powder (G) with 5 % eggshell powder (E) gave the highest compressive strength by about 16,37 %, 9,63 %, and 10,85 % at 7, 28, and 56 days, respectively compared to the control specimen. For the same mix, UPV increased by about 14,28 %, 6,66 %, and 6,8 % at 7, 28, and 56 days, respectively compared to the control specimens. The mix contains 10 % G with 15 % E powders impacted negatively on properties of concrete. The tensile strengths increased similarly to the compressive strengths, as they increased at 5 % E and began to gradually decrease when the compensation ratio was increased. Utilizing G and E wastes in concrete has been evaluated using an ANOVA statistical study. Analysis reveals that these wastes had a substantial impact on the strength and other variations of concrete properties, and the optimal E to be used with 10 % G is 5 %.

Keywords: ANOVA; Eggshell; Glass Powder; Compressive and Splitting Strength; Modulus of Rupture; UPV.

RESUMEN

La reutilización y el reciclado de residuos son formas eficaces de reducir la producción de residuos y, al mismo tiempo, resolver los problemas medioambientales asociados. Sin embargo, estas aplicaciones aún tienen mucho margen de mejora. En este artículo académico se analizan los residuos reciclados de vidrio y cáscara de huevo utilizados en la construcción. Se examina el impacto de estos residuos en características mecánicas específicas. Estos residuos se han utilizado como polvo y han sustituido parcialmente al cemento en el hormigón. A partir de los resultados, se descubrió que la utilización de un 10 % de polvo de vidrio (G) con un 5 % de polvo de cáscara de huevo (E) proporcionaba la mayor resistencia a la compresión en aproximadamente un 16,37 %, 9,63 % y 10,85 % a los 7, 28 y 56 días, respectivamente, en comparación con el espécimen de control. Para la misma mezcla, el UPV aumentó aproximadamente un 14,28 %, 6,66 % y 6,8 % a los 7, 28 y 56 días, respectivamente, en comparación con las muestras de control. La mezcla que contiene un 10 % de polvos G con un 15 % de polvos E repercutió negativamente en las propiedades del hormigón. Las resistencias a la tracción aumentaron de forma similar a las resistencias a la compresión, ya que aumentaron con un 5 % de E y empezaron a disminuir gradualmente al aumentar la relación de compensación. La utilización de residuos G y E en el hormigón se ha evaluado mediante un estudio estadístico ANOVA. El análisis revela que estos residuos tuvieron un impacto sustancial sobre la resistencia y otras variaciones de las propiedades del hormigón, y que el E óptimo a utilizar con un 10 % de G es del 5 %.

Palabras clave: ANOVA; Cáscara de Huevo; Polvo de Vidrio; Resistencia a Compresión y Rotura; Módulo de Rotura; UPV.

INTRODUCTION

The contemporary environmental movement seeks to totally or partially substitute trash for raw materials in the construction sector. This has many benefits for the development of sustainable systems in addition to assuring waste consumption and producing a cleaner, greener environment at a low cost.(1,2,3) Chen et al.(2), analyze how well eggshell and glass powder resists acidity and propose predictive modeling for cement-based composites modified with eggshell and glass waste to produce durable and environmentally friendly building components. The production of cement results in significant emissions of undesirable compounds, primarily CO2, which generate the greenhouse effect and raise global temperatures.(4) Additionally, the process of making cement requires a lot of energy and raw materials. By reducing the demand for cement (blended cement), technical advancements have been made to lessen the environmental impact of cement production.

In order to decrease energy consumption and CO2 emissions, numerous research studies have focused a lot of emphasis on mineral additives such as fly ash, rice husk ash, brick powder, waste eggshell powder (E), waste powder of glass (G), and other byproducts can be employed as pozzolanic materials in place of cement in addition to being used as fillers.(5,6,7,8) When crushed into very fine particles, G has been found to include a significant proportion of amorphous silica to induce pozzolanic conduct.(9,10) According to recent studies, pozzolanic activity in concrete has been demonstrated by grinding used glass into tiny particles. The waste glass that has been finely powdered is intended to act as a pozzolanic material for producing a new gel with a significant amount of hydration products.(10) Tamanna et al.(11) investigation focused on the pozzolanic activity of the cement paste's potential to produce cement gel (C-S-H). It demonstrated that for glass powder 75-38 m and 38 m at 90 days, Ca(OH)2 ( calcium hydroxide) formation reduced while the C-S-H formation rose.(12) E is suitable as a binder and can be utilized as a powder due to its high calcium content and chemical makeup, which is similar to that of limestone.(13,14) 10 % and 15 % E produced M25 concrete that was stronger than the control, according to Ansari et al.(15). The findings also demonstrated that tire rubber decreased the mechanical characteristics of concrete while E increased them at 5 % and 10 %.(16) The E has been used as fine aggregate but it has negative effect on mortar properties(17) it found to be more effective as powder.(14) Tan et al.(18) used E substitution for concrete at 10 % and 15 %. E replacement improved mechanical performance while also lengthening concrete's life cycle and reducing the rate of water absorption. Additionally, the addition of more than 5 %E to lightweight concrete used to partially replace cement resulted in a loss in compressive strength. SCC has been prepared using E with tiny tire rubber particles at intervals of 5 % to 15 %. According to Hilal et al. The greatest values were 78 and 8,6 MPa which were attained at 10 % EA for compressive and tensile strengths. Results revealed that rubber tires have very poor workability and changing EPs had no impact on the concrete flow.(19)

This work is a continuation of a series of practical experiments to demonstrate the effect of local waste on the properties of concrete. First, the effect of glass alone as a powder was studied and it was found that the best percentage at the age of 28 days is 10 %(4,7) and that the effect of glass as a pozzolanic material appears at later ages.(9) From the test results on the influence of local eggshell powder on concrete, it was found that eggshells work as accelerators, and its effect appeared at early ages.(5,14) Based on these results, a percentage of 10 % glass with different percentages of eggshells was chosen as a powder to take advantage of the properties of the two materials at early and late ages.

Materials and mix proportions

In this experimental work, all of the specimens' castings were done using CEM I (42,5 R) cement based to Iraqi Specification No. 5/2019.(20) Recycling shattered windows before incorporating the glass into the concrete, the glass was gathered and ground into powder. The strength activity index of the glass powder used in this work is 102 %, which complies with ASTM C311-05(21) standards for strength activity index. After thoroughly cleaning the raw eggshells with clean water, they were dried for 24 hours. The eggshells were dried and then put through a grinding machine. In order to replace cement, the resulting eggshell powder was run through a number 200 sieve.

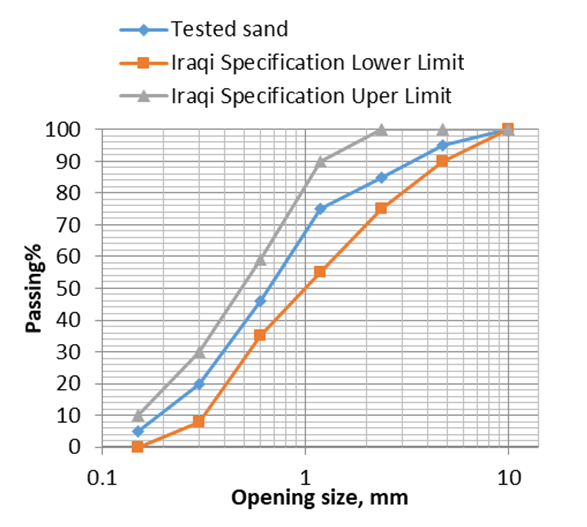

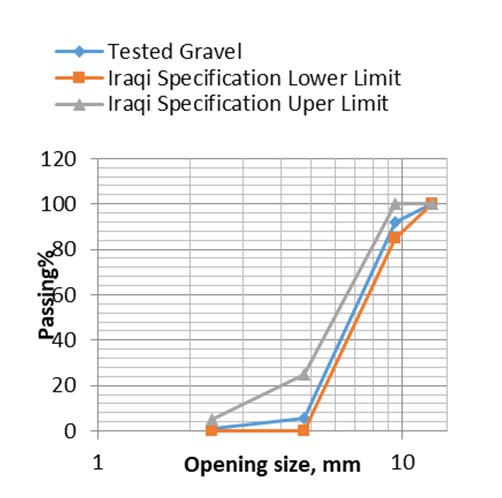

Specific gravities glass and eggshell were 2,42 and 0,85, respectively. The employed fine sand and coarse aggregate had a maximum particle size of 4,75 mm and 10mm with specific gravities of 2,58 and 2,75, respectively. Figures 1 and 2 depict the sieve analysis findings for the use of fine and coarse aggregates that adhere to Iraqi Specification No. 45.(22) Sika ViscoCrete-5930, a high-performance superplasticizer concrete admixture that satisfies ASTM C 494 requirements, is available in types G and F.(23)

A constant w/b ratio of 0,35 and a cement: sand: gravel ratio of 1:1,75:2,85 have been utilized in the production of concrete mixtures. 10 % of the G was mixed with E as a 5, 7,5, 10, 12,5, and 15 % of the total weight of the binder. By cement weight, 0,85 % superplasticizer was used. Figures 3 and 4 show how G and E are produced.

Figure 1. Sieve analysis of the tested sand

Figure 2. Sieve analysis of the tested gravel

Figure 3. Glass powder-producing procedures

Figure 4. Eggshell -producing procedures

Experimental tests

Testing was performed in accordance with ASTM C39-05,(10) ASTM C496-05,(11) and ASTM C78-15a,(12) respectively, for tests of compression, splitting strength, and modulus of rupture (Figure 5). BS (1881): Part 203(13) is also followed while doing ultrasonic tests. Calculating the velocity is as follows:

V = pulse velocity (m/s)= length (m)/test duration recorded (s).

Figure 5. Experimental tests

RESULTS AND DISCUSSIONS

Compressive strength

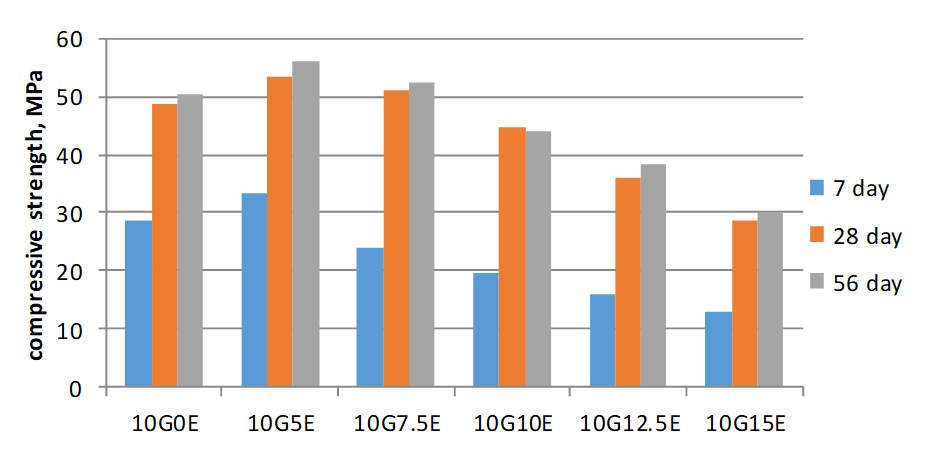

All specimens were experimentally cured for 7, 28, and 56 days. The compressive strength of control and concrete mixtures with various weight percentages of E and 10 %G is shown in figure 6. According to the findings, concrete mixtures improved their compressive strength by up to 10G7,5E. Additionally, by extending the curing age at the appropriate weight percentages of E, the compressive strength increased. Additionally, at all testing ages, the compressive strength values for 10G5E were greater than the reference specimen's compressive strength by about 16,37 %, 9,63 % and 10,85 % at 7, 28, and 56 % days. Additionally, the compressive strength was lower than the control mix because of the greater weight percentages of E.

When eggshell content increased, the cement paste's strength characteristics were marginally reduced. The shell membrane, which is made of organic materials including proteins, was the reason for this phenomenon. The findings of our study may be applied to the field of materials science to develop more environmentally friendly building materials.(29) However, replacing limestone up to 7,5 % of the weight seems to provide those of all ages with more compressive strength. These results agreed with those of Warzer et al.(30). They found that the compressive strength of concrete decreased as the proportion of lime increased. This may be explained by the pozzolanic reaction's water requirement, which is slower than the hydraulic reaction but only occurs in the presence of water that is readily available.

Figure 6. Results of compressive strength at different ages of testing

Splitting tensile strength

All specimens were experimentally cured for 7, 28, and 56 days to determine the splitting strength. The splitting strength is shown in figure 7. The findings showed that when the E level in concrete increased, the splitting strength gradually declined. Compared with the control mix, 10G5E produced the best results.

Figure 7. Results of splitting strength at different ages of testing

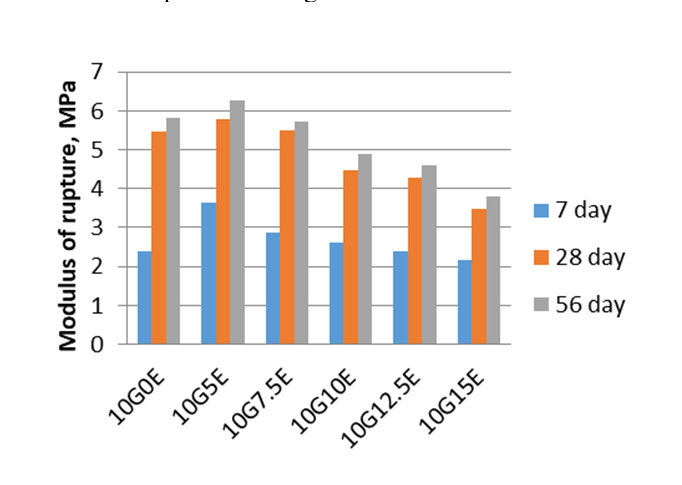

Modulus of rupture

All of the specimens were experimentally tested for modulus of rupture at 7, 28, and 56 days after curing (Figure 8). The findings showed that for any given weight percentage of E, the modulus of rupture rose as the curing age increased. Additionally, the addition of glass and eggshell as powder led to a progressive decline in the specimens' content greater than 5 % eggshell. The E content, which is regarded as lime, is obviously correlated with the concrete strength. It was discovered that all mixture strengths were lower than controls and fell off when natural lime concentration rose at the same age. According to findings, concrete's ability to acquire strength is substantially impacted by the quality of the E.(14)

Figure 8. Results of modulus of rupture at different ages of testing

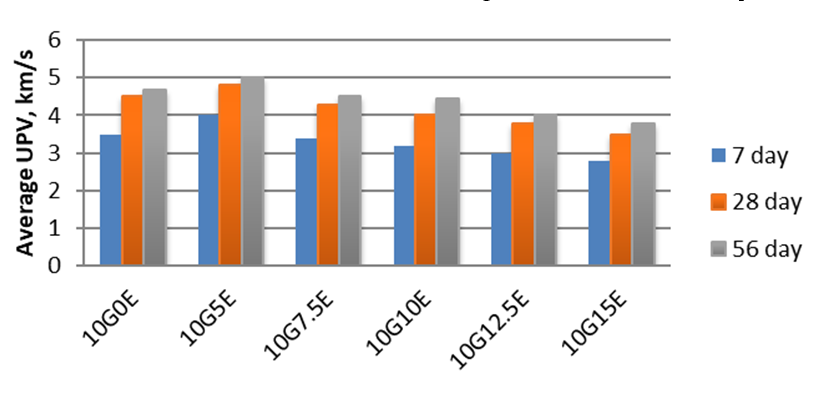

Ultrasonic tests

The UPV results are shown in figure 9. All specimens' UPVs were determined after 7, 28, and 56 days of cure. The results showed that the UPV rose as the curing age increased.

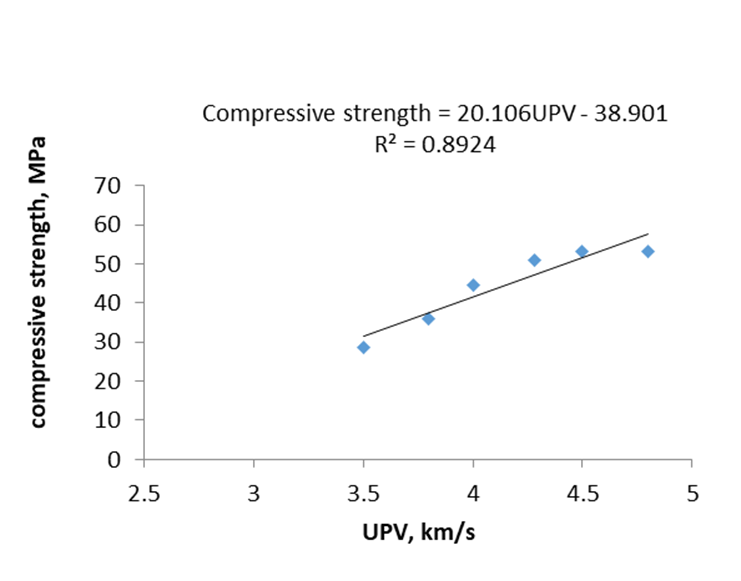

It must be assumed that concrete density, moisture content, and curing time are the key determinants of UPV. Because of this, larger UPV values were achieved at all weight percentages of E addition throughout the upper curing age interval. Except for 10G5E mixed in concrete specimens, the comparison of E addition produced lower UPV findings than the standard. In relation to curing age, the maximum value of UPV was found at 10G5E. The benefit of destructive tests is to predict the compressive strength of the structure. Therefore, it is important to find a relationship between compressive strength in terms of UPV (Figure 10) based on the results of the current work as follows:

Compressive strength = 20,106UPV - 38,901

Figure 9. Results of UPV at different ages of testing

Figure 10. Relation between compressive strength and UPV

Statical analysis

Using samples from each group, an ANOVA examines the degrees of variation in more than two groups. The first thing you should look at in an ANOVA test is the variation within each group that is determined by the independent variable; this variance is estimated using the values of the dependent variable within each of these groups.

The ANOVA test's capacity to simultaneously compare means across three or more groups is one of its main advantages. Using an ANOVA, researchers can examine differences among all groups in a single, comprehensive test. Two-way ANOVA offers two benefits when applied to a two-variable design: it may be used to examine the interaction between two independent variables and it increases statistical power because of the reduced variance. Neamat et al.(31) used the ANOVA statistical analysis to demonstrate the impact of substituting glass powder for cement. According to the test results, the compressive strength had to be increased by increasing the amount of cement in the mixture and substituting glass powder for cement.

In this work, E-content has been considered as the independent variable, while the properties have been considered as dependent variables. The effects of E content were examined using a statistical two-way ANOVA model in accordance with the findings of the experimental investigation.

The simulation of the optimization response also made use of the desirability function technique. Properties that were assessed in this investigation at various ages served as the main variables in the analysis. In the optimization study, these variables were regarded as dependent factors, whereas E content was regarded as an independent factor. According to the study process (Figure 11 and table 1), 5 % is the optimal E content to be utilized with 10 % glass for the best possible performance.

Figure 11. ANOVA analysis results

|

Table 1. Response Optimization (Multiple Response Prediction) |

||||

|

Response |

Goal |

Target |

Weight |

Importance |

|

56 day-UPV |

Maximum |

5,000 |

1 |

1 |

|

28 day-UPV |

Maximum |

4,800 |

1 |

1 |

|

7 day-UPV |

Maximum |

4,000 |

1 |

1 |

|

56-day-Modulus of rupture |

Maximum |

6,280 |

1 |

1 |

|

28 day--Modulus of rupture |

Maximum |

5,800 |

1 |

1 |

|

7 day-Modulus of rupture |

Maximum |

3,640 |

1 |

1 |

|

56 day--Splitting strength |

Maximum |

5,620 |

1 |

1 |

|

28 day-Splitting strength |

Maximum |

5,400 |

1 |

1 |

|

7 day-Splitting strength |

Maximum |

2,640 |

1 |

1 |

|

56 day--compressive strength |

Maximum |

55,890 |

1 |

1 |

|

28 day-compressive strength |

Maximum |

53,213 |

1 |

1 |

|

7 day-compressive strength |

Maximum |

33,213 |

1 |

1 |

Variable: E%

Setting: 5

CONCLUSIONS

Based on the findings of this work, the following conclusions have been drawn:

· By utilizing a small amount of eggshell as a powder with waste glass as a powder too, concrete's mechanical qualities can be improved.

· From the results, it was found that utilizing 10 %glass powder with 5 % eggshell powder gave the highest compressive strength by about 16,37 %, 9,63 %, and 10,85 % at 7, 28, and 56 days, respectively compared to the control specimen.

· The mix 10G5E gave the highest UPV by about 14,28 %, 6,66 %, and 6,8 % at 7, 28, and 56 days, respectively compared to the control specimen.

· The mix contains 10 % glass with 15 % eggshell impacted negatively on properties of concrete.

· The tensile strengths increased similarly to the compressive strengths, as they increased at 5 % eggshells and began to gradually decrease when the compensation ratio was increased.

· Utilizing waste glass and eggshells in concrete has been evaluated using a two-way ANOVA statistical study. According to statistical analysis, 5 % is the optimal eggshell content to be utilized with 10 % glass for the best possible performance.

REFERENCES

1. T.H. Mohammed, S.M. Hama, Effect of combination of waste glass powder and plastic aggregate on structural behavior of reinforced concrete beams, In: Structures.12 (2023) 83–103.

2. Z.Chen, M.N. Amin, B.Iftikhar, W.Ahmad, F. Althoey, F.Alsharari, Predictive modelling for the acid resistance of cement-based composites modified with eggshell and glass waste for sustainable and resilient building materials, J. Buil Eng.76(2023)107-325.

3. M.Y. Mohamed, S.M. Hama , A.Sh. Mahmoud , Shear behavior of reinforced concrete beams incorporating waste glass powder as partial replacement of cement, European Journal of Environmental and Civil Engineering. 27(2023) 2194-2209.

4. M. N. Amin, W.Ahmad,K. Khan,M.N. Al-Hashem, A.F.Deifalla,A. Ahmad, Testing and modeling methods to experiment the flexural performance of cement mortar modified with eggshell powder. Case Studies in Construction Materials.18(2023)181-759.

5. S. M.Hama, D. N.Hamdullah, H. M.Ashour, , Effects of Eggshell Powder as Partial Replacement of Cement on Flexural Behavior of One-Way Concrete Slabs" Journal of engineering science and technology. 14(2019)5.

6. Y.Hakeem, R. O.Abd-Al Ftah, B. A.Tayeh, R. D. A. Hafez, Eggshell as a fine aggregate replacer with silica fume and fly ash addition in concrete: A sustainable approach. Case Studies in Construction Materials.18(2023)18-42.

7. H.S.Ubeid, S.M.Hama, AS.Mahmoud, Mechanical properties, energy impact capacity and bond resistance of concrete incorporating waste glass powder, IOP Conf Series Mater Sci Eng. 745(2020)12-111.

8. S.S. Mansoor, S.M.Hama, D.N.Hamdullah, Effectiveness of replacing cement partially with waste brick powder in mortar. Available online 1 February (2022).

9. M.M Yassen, S.M.Hama, A.S.Mahmoud, Reusing of Glass Wastes as Powder as Partial of Cement in Production of Concrete, 11th International Conference on Developments in eSystems Engineering. (2018).

10. N .Tamanna, N.M .Sutan, R .Tuladhar, Lee. DTC, I .Yakub, Pozzolanic properties of glass powder in cement paste. Journal of Civil Engineering, Science and Technology. 7(2016)75-81.

11. G.M.S. Islam, M.H .Rahman, N.Kazi, Waste glass powder as partial replacement of cement for sustainable concrete practice. Int J Sustain Built Environ. 6(2017)37–44.

12. Y. Khudair, M.K. Mohammed, S. M. Hama, Optimization of glass powder content in self-compacting concrete as partial replacement of cement. IOP Conf, Sci Eng.(2020).

13. S. S. Mansoor, S. M. Hama, A. D. Ahmed, Efficiency of waste eggshell as powder on some mortar's fresh and hardened properties. AIP Conference Proceedings. (7)(2022)26-60.

14. D. N. Hamdullah, S. M. Hama, M. M. Yaseen, Effect of eggshell waste powder on impact resistance and bond charcteristics of reinforced concrete. Key Engineering Materials. 8(2019)21-28 .

15. M.M.Ansari, M.D.Kumar, J.M.Charles, G.Vani, Replacement of cement using eggshell powder, Int J Civ Eng.3 (2016)1-2.

16. R. Othman , B.W. Chong , P.J.Ramadhansyah, M .R .M. Hasan , M.M.A Al Bakri, M.H.W. Ibrahim, Evaluation on the rheological and mechanical properties of concrete incorporating eggshell with tire powder. Journal of materials research and technology.14(2021)439-451.

17. O. F. Rajab, Z. M. Ali, S. M. Hama. Influence of crushed eggshell content as fine aggregate replacement on cement mortars properties. AIP Conference Proceedings. (2023).

18. Yu. TY, D.S. Ing, C.S. Choo, M.A. Azed. Natural lime treated as partial cement replacement to produce concrete. Int J Adv Sci Eng Inf Technol. 7(2017)798-804.

19. N.Hilal, D.M. Saffar, T.K.Mohammed, Effect of eggshell ash and strap plastic waste on properties of high strength sustainable self-compacting concrete, Arab J Geosci. 14(2021).

20. Iraqi Specification No.5, "Portland Cement", the Cement Agency for Standardization and Quality Control, Baghdad. (2019).

21. ASTM: C311, "Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland–Cement Concrete", American Society of Testing and Material International. (2005).

22. Iraqi Specification No. 45, “The aggregate of natural source for concrete construction", Baghdad, (1984).

23. ASTM: C494, "Chemical Admixtures for Concrete", American Society of Testing and Material International, (2005).

24. ASTM: C39, "Compressive Strength of Cylindrical Concrete Specimens", American Society of Testing and Material International, (2005).

25. ASTM: C496, "Splitting tensile Strength of Cylindrical Concrete Specimens", American Society of Testing and Material International, (2005).

26. ASTM: C78-15a, "Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading)",” American Society of Testing and Material International, (2015).

27. BS 1881: Part-203,“Recommendations for Measurement of Velocity of Ultrasonic Pulses in Concrete”. British Standards Institution, London, (1986).

28. R.P.Khatri, V.Sirivivatnanon, Effect of different supplementary cementations materials on mechanical properties of high performance concrete, Cement and Concrete Research. 25(1995) 209-220.

29. S.Grzeszczyk, T.Kupka, A. Kałamarz, A.Sudoł, K.Jurowski, N.Makieieva, R.Wrzalik, Characterization of eggshell as limestone replacement and its influence on properties of modified cement. Construction and Building Materials. 12 (2022)3-19.

30. W.Qadir, K.Ghafor, A.Mohammed, Evaluation the effect of lime on the plastic and hardened properties of cement mortar and quantified using Vipulanandan model, Open Engineering. 9(2019) 468-480.

31. S.Neamat ,M. Hassan, A Review on Using ANOVA and RSM Modelling in The Glass Powder Replacement of The Concrete Ingredients. Journal Of Applied Science And Technology Trends. 2(2021) 72 –77.

FINANCING

The authors did not receive financing for the development of this research.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

AUTHORSHIP CONTRIBUTION

Conceptualization: Sheelan Mahmoud Hama, Husam K. K. Al-Ani, Ibrahim H Alfahdawi.

Data curation: Sheelan Mahmoud Hama, Husam K. K. Al-Ani, Ibrahim H Alfahdawi.

Formal analysis: Sheelan Mahmoud Hama, Husam K. K. Al-Ani, Ibrahim H Alfahdawi.

Research: Sheelan Mahmoud Hama, Husam K. K. Al-Ani, Ibrahim H Alfahdawi.

Methodology: Sheelan Mahmoud Hama, Husam K. K. Al-Ani, Ibrahim H Alfahdawi.

Drafting - original draft: Sheelan Mahmoud Hama, Husam K. K. Al-Ani, Ibrahim H Alfahdawi.

Writing - proofreading and editing: Sheelan Mahmoud Hama, Husam K. K. Al-Ani, Ibrahim H Alfahdawi.