Category: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

The Effect of Various Contents of Nano- Lime on The Properties of Self-Compacting Geopolymer Concrete Containing Micro-Steel Fibers

Efecto de diversos contenidos de nano-cal sobre las propiedades del hormigón geopolímero autocomapactante con microfibras de acero

Eman Hasan Raheem1 *, Haider M.Owaid1 *

1Civil Engineering Department, College Engineering, University of Babylon, Babylon, Iraq.

Cite as: Hasan Raheem E, Owaid HM. The Effect of Various Contents of Nano- Lime on The Properties of Self-Compacting Geopolymer Concrete Containing Micro-Steel Fibers. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:837. https://doi.org/10.56294/sctconf2024837

Submitted: 26-01-2024 Revised: 08-04-2024 Accepted: 04-06-2024 Published: 05-06-2024

Editor: Dr.

William Castillo-González ![]()

Note: Paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

The high carbon footprint of cement manufacture is the main disadvantage of Portland cement concrete, leading to contamination of the environment. Self-compacting geopolymer concrete (SCGPC) can effectively replace plain cement concrete in the construction sector for a sustainable environment. The need for high-performance concretes and green construction is rising day by day. This study has endeavored to investigate the effect of incorporating nano-lime (NL) particles at various contents of (0 %,1 %,2 %, and 3 %) by mass of calcined kaolin clay (CKC) on characteristics of fresh (flowability and passing ability), mechanical (the strengths of compression and flexural), and durability (porosity, and water absorption) for SCGPC reinforced with micro steel fibers based on CKC to enhance its performance. Three SCGPC mixes were made utilizing NL at 1 %, 2 %, and 3 % as a partial replacement for CKC; however, an additional mix was made with no NL. The mixes had a fixed total binder quantity (484 kg/m3) and a constant quantity of micro-steel fibers 0,5 % by volume. The findings showed that adding NL had a negative effect on fresh characteristics, though the mixes still satisfied the required criteria. However, With the addition of NL, especially at 2 % content, the mechanical and durability characteristics of SCGPC are considerably enhanced. Applying this amount of NL results in a 1,9 % reduction in the slump flow; however, it increases compressive strength by 20,95 %, 27,27 %, and 11,91 % for 3,7 and 28 days, respectively, and flexural strength by 17,41 % for 28 days. It also reduced the porosity of the SCGPC specimens and significantly improved the specimens’ resistance to water absorption. Based on the findings of present investigation, the recommended content of NL to be applied in SCGPC for the best performance is 2 %.

Keywords: Calcined Kaolin Clay; Geopolymer; Mechanical Characteristics; Micro Steel Fiber; Nano-Lime; Sustainability.

RESUMEN

La elevada huella de carbono de la fabricación de cemento es el principal inconveniente del hormigón de cemento Portland, que conduce a la contaminación del medio ambiente. El hormigón geopolímero autocompactante (SCGPC) puede sustituir eficazmente al hormigón de cemento simple en el sector de la construcción para conseguir un medio ambiente sostenible. La necesidad de hormigones de alto rendimiento y de construcción ecológica aumenta día a día. Este estudio se ha esforzado por investigar el efecto de la incorporación de partículas de nano-cal (NL) en diferentes contenidos de (0 %,1 %,2 %, y 3 %) en masa de arcilla de caolín calcinado (CKC) en las características de fresco (fluidez y capacidad de paso), mecánicas (las resistencias de compresión y flexión), y durabilidad (porosidad, y absorción de agua) para SCGPC reforzado con micro fibras de acero a base de CKC para mejorar su rendimiento. Se realizaron tres mezclas de SCGPC utilizando NL al 1 %, 2 % y 3 % como sustitución parcial del CKC; sin embargo, se realizó una mezcla adicional sin NL. Las mezclas tenían una cantidad total fija de ligante (484 kg/m3) y una cantidad constante de microfibras de acero del 0,5 % en volumen. Los resultados mostraron que la adición de NL tenía un efecto negativo sobre las características en fresco, aunque las mezclas seguían cumpliendo los criterios exigidos. Sin embargo, con la adición de NL, especialmente con un contenido del 2 %, las características mecánicas y de durabilidad del SCGPC mejoran considerablemente. La aplicación de esta cantidad de NL da como resultado una reducción del 1,9 % en el flujo de asentamiento; sin embargo, aumenta la resistencia a la compresión en un 20,95 %, 27,27 % y 11,91 % para 3,7 y 28 días, respectivamente, y la resistencia a la flexión en un 17,41 % para 28 días. También redujo la porosidad de las probetas SCGPC y mejoró significativamente la resistencia de las probetas a la absorción de agua. En base a los resultados de la presente investigación, el contenido recomendado de NL a aplicar en SCGPC para obtener el mejor rendimiento es del 2 %.

Palabras clave: Arcilla de Caolín Calcinada; Geopolímero; Características Mecánicas; Microfibra de Acero; Nano-Cal; Sostenibilidad.

INTRODUCTION

Modern technical advancements aim to create less dangerous, cheaper, and more effective substances. Hence, it is important to provide environmentally friendly and sustainable types of concrete due to carbon dioxide emissions linked to cement production.(1) Geopolymer is the eco-binder and novel advancement in the concrete industry in which Portland cement (PC) can be substituted by alumina-silicate sources such as materials of geological origin (calcined kaolin clay) or waste materials (fly ash & GGBFS), activated by a alkali solution to serve as a binder in concrete.(2) Geopolymer concrete (GPC) requires proper compacting to prevent failure because its high viscosity. Self-compacting geopolymer concrete (SCGPC) was presented as a solution to this issue.(3) Self-compacting concrete (SCC) spreads and fills the mold during heavy reinforcing without needing for vibration.(4) SCGPC is made by completely removing the PC and does not require vibration to be placed since it includes the advantages of both GPC and SCC.(5,6) Research on GPC production using fly ash as raw materials is predominantly published. However, 1 ton of cement of geopolymer involving 50 % fly ash associated with 16,5 tons of carbon dioxide emissions.(7) Also, Low-calcium fly ash was employed to create geopolymers, which often set gradually, have a large porosity, and have lower strength.(8) As a result, using fly ash to make geopolymer cement is not a long-term practical method. Generally ,The idea is to employ raw materials from geological resources such as calcined kaolin clay because they are widely available, more eco-friendly, and stable over time.(9) Calcined kaolin clay (CKC) is a product made from natural kaolin clay, containing high alumina and silica content, with a smaller environmental effect and lower extraction costs.(10) Several investigations indicate that adding different fiber types to GPC and normal concrete enhances their compressive, tensile, and flexural properties.(8,11) Notably, geopolymer concrete exhibits greater brittleness and a lower elastic modulus.(11) Hence, when micro steel fiber is added to geopolymer composites, crack initiation decreases, and the geopolymer’s mechanical properties are enhanced.(12) Several investigations indicate that geopolymers involving microfibers have better mechanical characteristics than those with no microfibers.(13,14) On the other hand, developing a balanced mix may be difficult since factors like the hydroxide solution’s molarity, the curing method, and the raw ingredients all impact GPC properties. As a result, the construction industry is adopting nanotechnology to improve geopolymer concrete performance.(15) Geopolymers are developed by ultrafine particles of powder with a scale of less than 100 nm, improving hardened properties by serving as fillers and nucleation sites and accelerating the stages of geopolymerization.(13,16,17) On the other hand, incorporating fiber with nanoparticles improves the specimens’ flexural and bond strength, densifying the matrix and preventing the pull-out of fibers.(13,18) Moreover, Safiuddin et al.(19) revealed that adding nanoparticles to concrete could decrease maintenance and rehabilitation costs. The previous studies on the incorporating of nanoparticles in GPC or SCGPC used either nano-silica(11,18,20) or nano-titanium oxide(1,21) with very little understanding of the impact of nano lime (i.e., nano-CaCO3(NC)). Moreover Raj et al.(22) claimed there was not enough literature on the incorporating of nano-lime in GPC. Nano-lime (NL) is cheaper because its abundant supply in limestone and marble, making it suitable for cementitious composites as a filler and nucleation agent.(23,24) However, new research by Assadi et al.(17) assessed the inclusion of Calcium Carbonate nanoparticles (NC) in geopolymeric paste based on fly ash up to a 3 % content. While increasing the amount of NC to 2 % enhanced the mechanical characteristics of geopolymer composites, increasing it to 3 % decreased GPC mechanical performance. On the other hand, Ge (25) examined the effects of NC of various doses and sizes on SCC and paste of cement, finding that increasing NC increases compressive strength while decreasing strength as particle size increases also showed that Concrete with low concentrations (≤2,5 %) showed satisfactory workability. Hosan and Shaikh(26) assessed the impact of inclusion of nano Calcium Carbonate particles on the durability and the compressive strength of concretes made from slag and slag/fly ash with high-volume . Results showed that 1 % NC enhanced strengths of compression and reduced water absorption and permeable void volume after 28 days, but a higher decrease was noted during 90 days of curing. Based on the published literature review, up to date, it is evident that no studies have examined the effect of the blending nano-lime with calcined kaolin clay on properties of SCGPC reinforced with micro-steel fibres based on calcined kaolin clay. For example, Alomayri(13) assessed the impact of Multiple concentrations of NC on the mechanical performance of geopolymeric paste reinforced with micro-steel fiber based on fly ash (not calcined kaolin clay). Also, recent work by Bheel et al.(27) assessed the properties of SCGPC based on metakaolin (i.e. calcined kaolin clay) by adding millet husk ash and wheat straw as a partial replacement for metakaolin, but nano-lime with various contents was not added as was studied in current research. Hence, the present experimental study aims to investigate the effect of various amounts of NL particles (0 %, 1 %, 2 %, and 3 %), a partial replacement for calcined kaolin clay on the properties of SCGPC-containing 0,5 % micro-steel fibers, these characteristics included workability, the strengths of compression and flexural, porosity, and water absorption. The current research offers a new method for enhancing strength and durability by using a novel combination (CKC+NL) as an eco-binder in manufacturing SCGPC reinforced with steel fiber. The outcomes of the present study can be valuable for better the performance of new SCGPC products that are suitable for construction applications along with the consumption of locally sourced raw materials with lower carbon footprints, thus advancing the trend toward sustainable building practices.

Experimental Work

Material

The materials required to create SCGPC mixtures for the present research are displayed in figure 1. The materials are as follows:

Calcined Kaolin Clay (CKC). Calcined kaolin clay was produced using Iraqi kaolin clay from western Iraq (Dewekhla region, Al-Anbar Governorate). After being ground, the kaolin clay was burned for one hour in a furnace up to 700ºC ± 20ºC following to Ibrahem and Wahab.(28) After that, the CKC was milled to a high fineness. Table 1 and Table 2 show that calcined kaolin clay’s chemical analysis and physical characteristics (CKC) comply with ASTM C618.(29)

Nano- Lime (NL). In this study, powder of nano-lime is supplied from China, the product center in Hangzhou, with a specific surface area of 40 m2/g, purity ≥ 94,5 %, a white colour, and a particle size of 80 nm.

Sodium Hydroxide (NaOH). Sodium hydroxide (NaOH) in the form of solid flakes available commercially with 99 % purity was used in the current study. NaOH solution was created by melting the Sodium hydroxide solid flakes in distilled water. Additional information on the NaOH solution used in this experiment is provided in ASTM E291.(30)

Sodium silicate (Na2SiO3). sodium silicate (Na2SiO3) in solution form was used in this study and was produced in the U.A.E. The properties of Na2SiO3 solution are Na2O% content (13,1–13,7), SiO2 % content (32–33), density (51), specific gravity (1,534–1,551), and viscosity (600-1200).

Water. To improve workability, drinking tap water was added to the SCGPC mix, which conforms with Iraqi Specification.(31)

Superplasticizer. A Commercially available chemical admixture (Sika Viscocrete-180G) from Sika Iraq was employed to advance the workability to the required level for SCGPC. It conforms to requirement of ASTM C 494 (32) type F, doesn’t include chloride, and possesses specific gravity of 1,065± (0,005) g/cm3.

Micro Steel Fibers. A micro steel fiber that is straight and has an aspect ratio of 65 is displayed in Table3.

Coarse Aggregate. The coarse aggregate used in this study conforms to Iraqi specification requirements IQS No. 45 (33) and has the following properties: a maximum size of 10 mm, 0,5 % absorption, 0,03 % SO3 concentration, and specific gravity of 2,6.

Fine Aggregate. A naturally formed sand taken from the Al-Ekhadir region (Karbala city) that complied with zone III of Iraqi Specification requirements IQS No. 45 (33) was employed and it has the following qualities: SO3 concentration of 0,3 %, 2,65 specific gravity, 2,6 % absorption and 2,47 fineness modulus.

|

Table 1. Chemical compositions of calcined kaolin Clay (CKC) |

|||||||||

|

Oxides of CKC |

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

SO3 |

Na2O |

K2O |

L.O.I |

|

Content (Percent %) |

54,7 |

37,4 |

1,72 |

0,84 |

0,42 |

0,13 |

0,37 |

0,54 |

2,91 |

|

ASTM C618 requirements |

Sum of values more than 70 % |

|

|

Max 4 % |

|

|

Max 10 % |

||

|

Table 2. The calcined kaolin clay’s physical characteristics |

||||

|

Property |

Fineness (m2/kg) |

Specific gravity |

Median particle size (µm) |

Color |

|

CKC |

1640 |

2,61 |

14,3 |

Off-White |

|

Table 3. Characteristics of micro–Steel Fiber according to Manufacture |

||||||

|

Properties |

L. (mm) |

Dia. -(mm) |

Dens. (kg/m3) |

Tensile strength |

Aspect ratio |

M.O. E. (GPa) |

|

Micro Steel Fiber |

13 |

0,2 |

7800 |

2600 |

65 |

250 |

Figure 1. Ingredients employed for the making of SCGPC mixes

Self-Compacting Geopolymer Concrete Manufacturing

Alkaline Solution Preparation

Alkaline solution is essential in the manufacturing of geopolymers because its ability to dissolve silica and alumina and catalyze the polymerization reaction.(34) NaOH solution and Na2SiO3 solution were combined to create an alkaline solution for this study. The alkali solution must be supplied first before creating SCGPC, left alone for twenty minutes, and then employed. the proportion of Na2SiO3 solution to Sodium hydroxide solution was set at 2,5:1 and the ratio (Alkali liquid /binder) was maintained at 0,5. The alkali solution weight was divided by 3,5 to obtain the sodium hydroxide solution weight, whereas the sodium hydroxide solution weight was multiplied by 2,5 to obtain the Na2SiO3 solution weight. The concentration of the NaOH solution was maintained at 12 (mole/L), so to produce One kilogram of sodium hydroxide solution, 36,2 % of solid flakes were used. The weight of sodium hydroxide flakes is displayed in table 4.

|

Table 4. A Quantity of sodium hydroxide solids for 1 kg of solution for different molarities and NaOH weight concentrations (35,36) |

|||||

|

Molarity (mole/L) |

8 |

10 |

12 |

14 |

16 |

|

Sodium Hydroxide weight concentration % |

26,2 |

31,4 |

36,2 |

40,4 |

44 |

|

Weight NaOH of Flakes (g) |

262 |

314 |

362 |

404 |

440 |

|

Weight of Water (g) |

738 |

686 |

638 |

596 |

560 |

Preparation, Mixing and Samples Curing

Four mixes were created: three with NL substituted with CKC at 1 %, 2 %, and 3 % by mass, and one control mix containing no NL. However, for all the mixes the total binder content(B) was kept at 484 kg/m3. According to previous studies,(13,20,27) micro Steel fibers were additionally incorporated to all mixes at a fixed level of 0,5 % by volume of the overall mixture of SCGPC. The mix proportions are presented in Table 5. Moreover, the stages of mixing involved mixing the dry ingredients (CKC, fine and coarse aggregate) for two and a half minutes. Then, gradually put the previously made liquid including water, superplasticizer and an alkaline solution to the mixer for three minutes, shaking liquid with each addition. In addition, the steps provided by Shahrajabian & Behfarnia (38) were used for dispersing nano lime. However, to prevent clumping and clustering, fibers added by hand to the mixer.(39) Also, after fresh SCGPC testing and casting specimens without undergoing compaction, these specimens rested for 24 hours at ambient conditions, along with the molds; after that, they were demolded and heated to 60 Co for just one day. The specimens were then maintained at room temperature (between 22 and 30 Co) and covered with plastic until the day of testing to minimize moisture loss. See figure 2a and figure 2b.

Figure 2. Preparation of SCGPC samples: (a) cast specimens (b) Casting samples are covered in plastic until the day of testing

|

Table 5. mix proportions of SCGPC (kg/ m3) |

||||||||||

|

Mix |

Mix Symbol |

CKC |

NL |

w/ B By mass |

NaOH solution |

Na2SiO3 solution |

Fine agg |

Coarse agg |

SP% By mass of (B) |

Micro steel fiber |

|

Control Mix (100 %CKC +0 %NL) |

SCGPC0 |

484 |

0 |

0,4 |

69 |

173 |

850 |

862 |

3,5 |

39 |

|

99 %CKC+1 % NL |

SCGPC1 |

479,16 |

4,84 |

0,4 |

69 |

173 |

850 |

862 |

3,5 |

39 |

|

98 %CKC+2 %NL |

SCGPC2 |

474,32 |

9,68 |

0,4 |

69 |

173 |

850 |

862 |

3,5 |

39 |

|

97 %CKC+3 %NL |

SCGPC3 |

469,48 |

14,52 |

0,4 |

69 |

173 |

850 |

862 |

3,5 |

39 |

Testing Procedure

Fresh properties

The fresh characteristics of SCGPC mixtures were investigated using European guidelines for SCC,(4) including flowability and passing ability via slump flow, V-funnel, and L-box tests, as shown in figure 3.

Figure 3. Fresh characteristics tests: (a) test of L-Box (b) V- Funnel Flow Time and (C) Slump Flow test

Mechanical properties

In this research, the mechanical characteristics for each of the four SCGPC mixes were examined, comprising both flexural and compressive strength. At the age of 3, 7and 28 days, the compressive strength test was conducted according to BS EN 12390-part 3 (40) employing 10 cm cube specimens. At the age of 28 days, The test method a three-point loading described in ASTM C78 (41) was carried out to measure the flexural strength employing 10 × 10 × 40 cm prisms.

Durability Properties

Measurements of porosity and water absorption were performed to assessed the quality of SCGPC specimens. At the age of 28 day, SCGPC cube samples (100 ×100 ×100) mm3 were tested for water absorption and porosity using the methodology described in ASTM C642.(42) The water Absorption test includes drying specimens at 110 °C oven temperature to a consistent mass, then immersing them in water until totally saturated. The dry and saturated surface-dry specimens were then weighed. The water absorption values were obtained employing this equation:

Water Absorption (%) = (Wssd - Wd) / Wd * 100 (1)

where Wssd is the saturated dry surface weight, and Wd is the dry weight.

The Porosity’s value was determined employing the following Equation:

Porosity (%) = Wssd - Wd / Wssd - Wd * 100 (2)

where Ww refers to the saturated specimen’s weight in water.

RESULTS AND DISCUSSION

Fresh Properties

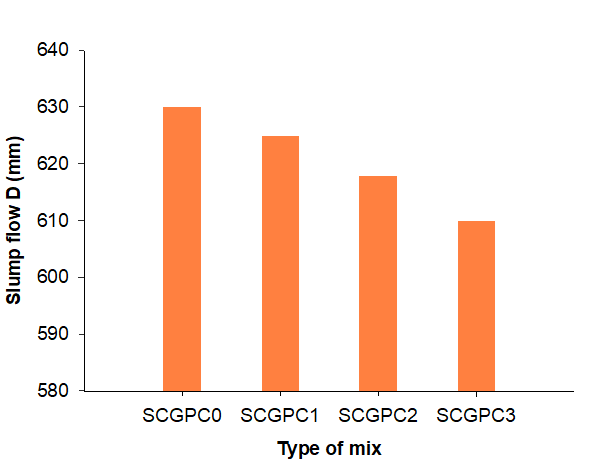

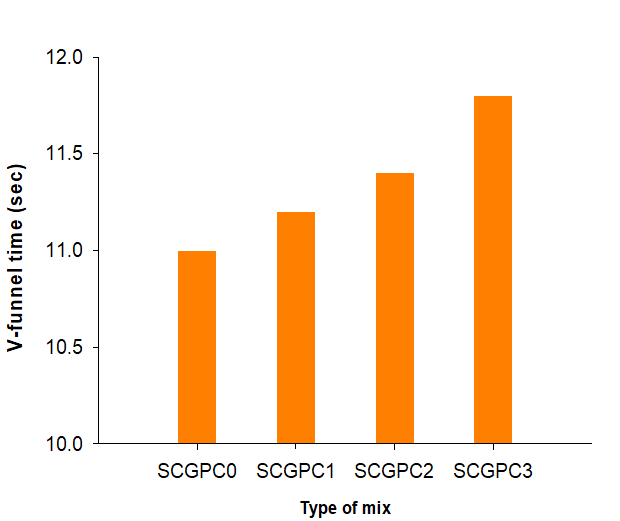

Table 6 and figures 4 and 6 provide the findings of the fresh characteristics of all SCGPC mixes. According to published studies, lime nanoparticles increased the water needed for concrete because of the larger surface area and tiny size of particle. As a result, fresh concrete became less workable. In the course of this study, this theory was verified. The reduction in workability was caused by including nano lime as a partial replacement for CKC in SCGPC. The increased surface area of nano lime particles more than CKC may help to explain this. The nano-lime mixes generally showed lower performance in fresh characteristics than the control mix. These effects of nano lime on SCGPC’s fresh characteristics were similar to those found by Ge(43) and Kadhum and Owaid.(23) They found that adding nano-lime to SCC leads to decreased slump flow diameter, L-box height ratio, and increased V-funnel flow times (i.e., increased mixture viscosity). The following paragraphs covered the impact of nano lime on each fresh property test.

|

Table 6. Fresh Properties Results |

||||

|

Mix |

Mix Symbol |

Diameter of the slump flow (mm) |

Flow time of V-funnel (TV) (sec) |

Blocking Ratio (BR) |

|

Control Mix 100 %CKC+ 0 %NL |

SCGPC0 |

630 |

11,0 |

0,867 |

|

99 %CKC + 1 %NL |

SCGPC1 |

625 |

11,2 |

0,864 |

|

98 %CKC + 2 %NL |

SCGPC2 |

618 |

11,4 |

0,860 |

|

97 %CKC +3 %NL |

SCGPC3 |

610 |

11,8 |

0,852 |

Slump Flow Test

Figure 4 exhibits the slump flow test findings. All the mixes had slump flow diameters within the 550–650 mm EFNARC range. The mix SCGPC1(control) achieves a maximum value of slump flow diameter of 630 mm. The flow of various SCGPC mixtures decreases as nano lime content increases, which could be caused by the fact that the particles of nano lime are very small and have a larger surface area. Also, the slump flow’s final spread was visually inspected, and no segregation was seen.

Figure 4. impact of NL contents on slump flow

V-funnel test

All four mixes were tested through the test of V-funnel to determine the flowability and stability of fresh SCGPC. In figure 5, the test outcomes for the V-funnel flow times are shown. Based on the findings of test, the V-funnel flow time (TV)changes between 11,0 and 11,8. The SCC is divided into two categories, VF1 (≤ 8 sec) and VF2 (9–25 sec), according to EFNARC standards.(4) The outcomes of the flow time (TV) of all mixes were within the VF2 category, which indicates an increase in viscosity when adding nano-lime and, at the same time, an improvement in segregation resistance. The minimum time (TV) of 11,0 Sec is noted for the control mix containing 100 %CKC without NL. Moreover, the fluidity of concrete diminishes as nano-lime concentration rises. As a result, the V-funnel’s flow time lengthens. The exact causes and mechanisms cited for the slump flow test findings also dictate explanations for the findings of the test of V-funnel.

Figure 5. impact of NL contents on V-funnel flow time

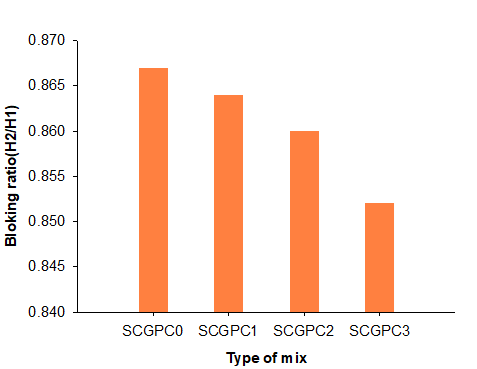

L-Box Test

Figure 6 displays the blocking ratio (BR=H2/H1) for various SCGPC mixtures. The findings of the BR varied from (0,867-0,854). When evaluating the fresh concrete for its ability to pass through an L-box’s bars, it is found that all four mixes flow through the bars without any blockage. The L-box test’s findings illustrate that BR decreases gradually as the nano-lime content increases. The greater the nano-lime concentration, the lower the blocking ratio. The passing ability of all SCGPC mixtures was adequate (BR ≥ 0,8) per EFNARC guidelines.

Figure 6. impact of NL contents on L-box blocking ratio

Mechanical Properties

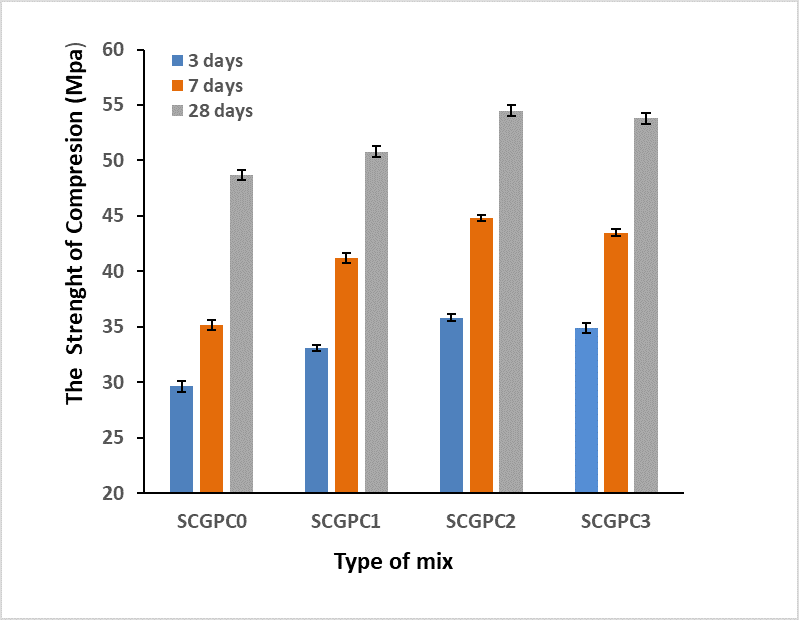

Compressive strength

The compressive strength of hardened concrete is a crucial property that aids in assessing the degree of geopolymerization. Figure 7 and table7 demonstrate the findings of Compressive strength of all SCGPC mixes. For every testing age, the compressive strengths of SCGPC with 1 %, 2 %, and 3 % NL replacement are greater than control Mix SCGPC0 (0 % NL), as demonstrated in figure 3. This improvement and acceleration of strength growth are attributed to the nucleation of hydration products as well as the effects of nano-fillers produced by the incorporation particles of NL , which helps seal the nano and miniature voids between the micro steel fibres and the geopolymer matrix combined with nano- Lime’s ability to revive the geopolymerization cycle.(13) The addition of NL can speed up the geopolymerization process since they can provide as nucleation sites for the useful products to form inside the SCGPC.(18,44) The strength of compression of mixes including 1 and 3 % NL is higher than that of the control mix by (11,82 %,17,10 %, and 4,31 %) and (17,91 %, 23,60 %, and 10,47 %), for ages 3,7 and 28 days, respectively. However, the mixture containing 2,0 % NL demonstrated the highest increases in strength of compression. The authors conclude that the optimum content of nano-lime is 2 %, which increases the strength of compression by 20,95 %, 27,27 %, and 11,91 % for ages 3,7 and 28 days, respectively, compared to the control, indicating optimal reactivity due to good nano-lime particle dispersion created more geopolymer gels as well as act as a filler to fill nano and micro-voids in SCGPC.(20) This outcome is comparable with that of nano-caco3-fly ash geopolymer composite reported by Assaedi et al.(17), who found that the optimum addition of nano-CaCO3 to fly ash geopolymer mixes approximately 2,0 %, which increases the compressive strength of the nano-geopolymer composites by 57,12 % over the reference mix at the age of 28 days. Both investigations show that increasing the proportion of NL lead to enhancement in compressive strength of the samples. This finding may also be attributed to the influence of the nano-lime, which enhanced the matrix via the geopolymer reaction, resulting in a greater content of geopolymeric products. The outcomes of this investigation show that the addition of nano-lime beyond content of 2 % reduces the strength of compression, but not less than that of the control mix of SCGPC may be attributable to the agglomeration of NL due to of adding excessive nano-lime particles making the matrix weak.(13,17,45)

|

Table 7. The outcomes of the compressive strength test |

||||

|

Mix |

Mix Symbol |

Strength of compression (MPa) |

||

|

3 days |

7days |

28days |

||

|

Control Mix 100 %CKC+ 0 %NL |

SCGPC0 |

29,6 |

35,2 |

48,7 |

|

99 %CKC + 1 %NL |

SCGPC1 |

33,1 |

41,2 |

50,8 |

|

98 %CKC + 2 %NL |

SCGPC2 |

35,8 |

44,8 |

54,5 |

|

97 %CKC +3 %NL |

SCGPC3 |

34,9 |

43,5 |

53,8 |

Figure 7. Impact of NL contents on strength of compression

Flexural Strength

Figure 8 demonstrates the outcomes of the flexural strength test for various SCGPC mixes containing 0,5 % micro-steel fibers with and without NL. Like compressive strength, NL addition also enhanced the flexural strengths of SCGPC mixtures. The improved interfacial connection between fiber and matrix was believed to cause this. The strength of flexural of SCGPC0 achieves 5,80 MPa, while mixes SCGPC1, SCGPC2, and SCGPC3 reach a strength of 6,23,6,81and 6,59 MPa, respectively, increasing about 7,41 %, 17,41 %, and 13,62 % compared with the strength of the control mix. The flexural strength of all mixes, including NL, was greater than that of the control; however, the mix SCGPC2 containing 2,0 % NL showed the highest value of flexural strength increase of 17,41 %, compared to the control, indicating that adding 2 % NL is the optimum proportion to increase the flexural strength. The enhancement can be attributable to the combined effect of NL and micro-steel fibers, resulting in a denser matrix and inhibiting the fiber pull-out due to the interfacial bonding between the micro-steel fiber and matrix is improved.(18,20,45) In a similar study, Alomayri(13) showed that adding 1-2 % nano-CaCO3 to the fly-ash geopolymer mix, including 0,5 % by volume micro steel fiber, improved the flexural strength, and using 2 %NL produced a maximal value of flexural strength reaching approximately 71,47 % of that of the control mix. Both studies show enhanced flexural strength due to NL enhancing the microstructure and accelerating the geopolymerization reaction, leading to the densification of the geopolymer matrix. However, Assaedi(44) found similar trends in fly ash-based geopolymers reinforced with polyvinyl alcohol fibres, which includes nano-CaCO3 with various contents of (1 %, 2 %, and 3 % by weight). He concluded that geopolymer composites showed improved flexural strength at all nano-CaCO3 measurements and discovered that employing more than the optimal amount of 2,0 % caused a slight decline of flexural strength because of the weaker interfacial bond between geopolymer matrix and fibers because of the non-uniform dispersion of NL causing nano particles agglomerate and less compact geopolymer matrix.

Figure 8. Effects of NL contents on Flexural strength

Durability Properties

Porosity and Water Absorption

Table 8 displays the porosity and water absorption results for each SCGPC mix. The incorporation of NL reduced proportionally the porosity and water absorption of all SCGPC mixes compared to reference mix (SCGPC0). Based on the outcomes of this study, the optimum proportion of NL was founded as 2,0 % by mass, which decreased the porosity by10,30 % and water absorption by 13 % as compared with the control mix. The pore-filling abilities of NL particles helped to decrease these characteristics.(46) Similar observation was noticed by Al Ghabban et al.(47) who explained the effect of using NL in conventional concrete with proportions (0-4 %) on the durability of concrete and found the optimum content of NL is 3 %, decreases water absorption about 21,42 % over control may be attributed to the addition NL led to much denser microstructure. However, adding excessive quantities of nano-lime beyond the optimum content (2 %) increased both of these characteristics of all samples but still lower than control mix, possibly due to agglomeration effect resulting from more nanoparticles addition.(46) These outcomes on the influence of NL are in agreement with those previously published by Shaikh and Supit(48) on conventional concrete containing high volume fly ash and Khotbehsara et al.(49) on self-compacting mortar.

|

Table 8. Water absorption and porosity for SCGPC mixes |

|||

|

Mix |

Mix Symbol |

Porosity (%) |

Water absorption (%) |

|

Control Mix 100 %CKC+ 0 %NL |

SCGPC0 |

11,50 |

4,15 |

|

99 %CKC + 1 %NL |

SCGPC1 |

11,12 |

3,97 |

|

98 %CKC + 2 %NL |

SCGPC2 |

10,32 |

3,61 |

|

97 %CKC +3 %NL |

SCGPC3 |

10,62 |

3,75 |

CONCLUSIONS

Practical and Theoretical Implications of Outcomes

According to the outcomes of the current study on SCGPC containing micro- steel fiber, the following are the main conclusions.

1. The flowability and passing ability declined with an increasing NL content However, the findings of each test for all mixes were within the EFNARC ran.

2. the study found that adding nano-lime at various amounts (1 %, 2 %, and 3 % by mass) enhanced mechanical, and durability properties at all ages compared with the control mix with no NL.

3. The findings from this study show that the enhancement value in the studied characteristics is low if the nano-lime content exceeds 2 %. Moreover, for economic considerations, this ratio is optimal to use in SCGPC.

4. The optimum ratio of addition NL is 2 %, which increases the compressive strength by 20,95 %, 27,27 %, and 11,91 % for 3,7 and 28 days, respectively, compared to the control mix, and it is also increases flexural strength by 17,41 % for 28 days. The improvement can be related to the ability of enough nano lime to hinder micro and nanovoids in the matrix because NL can accelerate the geopolymerization process, improving the bond between the microfibers and SCGPC components.

5. Regarding the development of durability properties, it was noted that the addition of 2,0 % NL had the lowest porosity and water absorption (10,30 % and 13 % less than the control mixture for porosity and water absorption, respectively). This indicates that particles of nano-lime play a pore-filling role to decrease the porosity of SCGPC.

6. This investigation underscores the potential of use nano-lime (NL) particles with optimum content 2 % in SCGPC providing low-carbon binder for producing sustainable SCGPC with better the performance thus Promoting the movement towards Sustainable high-performance concrete construction practices.

RECOMMENDATIONS

From this study, the following can be recommendations for future works:

1. Studying the behavior of nano-lime particles in SCGPC based on alkali activated CKC at the later ages (such as 180 and 360 days).

2. Studying microstructure properties for SCGPC samples at various ages using SEM, XRD, and BET techniques.

3. Studying the effects of different curing methods on performance of SCGPC such as steam curing and curing by sun light.

4. Investigating other the durability characteristics of SCGPC contained nano-lime (for example corrosion resistance, acid resistance, carbonation and sulfate attack).

REFERENCES

1. N. H. Jumaa, I. M. Ali, M. S. Nasr, and M. W. Falah, Strength and microstructural properties of binary and ternary blends in fly ash-based geopolymer concrete,Case Stud. Constr. Mater. 17 )2022( 01317.

2. M. Kumar, Geopolymer concrete: Leading the World towards a sustainable future, Int. J. Eng. Res. 4 (2015) 302–306.

3. P. U. Praveen and K. Srinivasan, Self-compacting geopolymer concrete - A review, IOP Conf. Ser. Mater. Sci. Eng. 263 (2017)

4. EFNARC, European Guidelines for Self-Compacting Concrete, Specification and Production and Use, Association House, UK. (2005)

5. M. F. Nuruddin, S. Demie, and N. Shafiq, Effect of mix composition on workability and compressive strength of self-compacting geopolymer concrete, Can. J. Civ. Eng. 38 (2011) 1196–1203.

6. Mohsen and H. M. Owaid, Assessing Fresh Properties and Compressive Strength ofcalcined kaolin based self-compacting geopolymer concrete incorporating waste powder materials, AIP Conf. Proc. ( 2023)

7. J. Davidovits, A continent is on fire: STOP promoting fly ash-based cements., Geopolymer Institute. (2020)

8. T. Alomayri, Performance evaluation of basalt fiber-reinforced geopolymer composites with various contents of nano CaCO3, Ceram. Int. 47 (2021) 29949–29959.

9. J. Davidovits and R. Davidovits, Ferro-Sialate Geopolymers (-Fe-O-Si-O-Al-O-), Geopolymer Inst. Libr. (2020)

10. A. M. Okashah, F. F. Zainal, N. F. Hayazi, M. N. Nordin, and A. Abdullah, Pozzolanic properties of calcined clay in geopolymer concrete: A review, AIP Conf. Proc. 2339 (2021).

11. P. Zhang, K. Wang, J. Wang, J. Guo, S. Hu, and Y. Ling, Mechanical properties and prediction of fracture parameters of geopolymer/alkali-activated mortar modified with PVA fiber and nano-SiO2, Ceram. Int. 46 (2020) 20027–20037.

12. M. S. Amouri and N. M. Fawzi, The Mechanical Properties of Fly Ash and Slag Geopolymer Mortar with Micro Steel Fibers, Eng. Technol. Appl. Sci. Res. 12 (2022) 8463–8466,

13. T. Alomayri, Mechanical and fracture behaviour of micro steel fibre-reinforced fly ash-based geopolymer paste containing nano CaCO3, J. Taibah Univ. Sci. 15 (2021) 391–406.

14. S. Riahi, A. Nemati, A. R. Khodabandeh, and S. Baghshahi, Investigation of interfacial and mechanical properties of alumina-coated steel fiber reinforced geopolymer composites, Constr. Build. Mater. 288 (2021) 123118.

15. B. J. Arpitha and P. Parthasarathy, Effect of nano-alumina and graphene oxide on the behavior of geopolymer composites: A state of the art of review, Mater. Today Proc. (2023)

16. J. Tanzadeh, Laboratory evaluation of self-compacting fiber-reinforced concrete modified with hybrid of nanomaterials, Constr. Build. Mater. 232 (2020) 117211.

17. H. Assaedi et al., Characterization and properties of geopolymer nanocomposites with different contents of nano-CaCO3,Constr. Build. Mater. 252 (2020) 119137.

18. M. E. Gülşan, R. Alzeebaree, A. A. Rasheed, A. Niş, and A. E. Kurtoğlu, Development of fly ash/slag based self-compacting geopolymer concrete using nano-silica and steel fiber, Constr. Build. Mater. 211 (2019) 271–283.

19. M. Safiuddin, M. Gonzalez, J. Cao, and S. L. Tighe, State-of-the-art report on use of nano-materials in concrete, Int. J. Pavement Eng. 15 (2014) 940–949.

20. T. Alomayri, A. Raza, and F. Shaikh, Effect of nano SiO2 on mechanical properties of micro-steel fibers reinforced geopolymer composites, Ceram. Int. 47(2021) 33444–33453.

21. K. V. S. G. K. Sastry, P. Sahitya, and A. Ravitheja, Influence of nano TiO2 on strength and durability properties of geopolymer concrete, Mater. Today Proc. 45 (2021) 1017–1025.

22. R. S. Raj, G. P. Arulraj, N. Anand, B. Kanagaraj, E. Lubloy, and M. Z. Naser, Nanomaterials in geopolymer composites: A review, Dev. Built Environ. (2022) 100114 .

23. A. O. Kadhum and H. M. Owaid, Experimental investigation of self-compacting high performance concrete containing calcined kaolin clay and nano lime, Civ. Eng. J.6(2020) 1798–1808.

24. T. Hakuzweyezu, H. Qiao, C. Lu, J. Twagirumukiza, and B. Yang, Life Prediction of Concrete Mixed with Nano-CaCO 3 in Semi-Immersed Corrosive Environment, ACI Mater. J. 119 (2022) 51–62.

25. Z. Ge, Properties of self-consolidating concrete containing nano-CaCO3, J. ofSustainable Cem. Mater. 3 (2014) 37–41.

26. A. Hosan and F. U. A. Shaikh, Compressive strength development and durability properties of high volume slag and slag-fly ash blended concretes containing nano-CaCO3, J. Mater. Res. Technol. 10 (2021) 1310–1322.

27. N. Bheel, P. Awoyera, I. A. Shar, S. A. Abbasi, and S. H. Khahro, Synergic effect of millet husk ash and wheat straw ash on the fresh and hardened properties of Metakaolin-based self-compacting geopolymer concrete, Case Stud. Constr. Mater. 15 (2021) e00729.

28. A. M. Ibrahem and K. A. Wahab, Effect of temperature on the pozzolanic properties of metakaolin produced from iraqi kaolin clay, AL-Fatih J. 10 (2008) .

29. ASTM C618, Specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. American Society for Testing and Materials (ASTM) International,West Conshohocken, Pennsylvania., (2005).

30. ASTM E291, Standard Test Methods for Chemical Analysis of Caustic Soda and Caustic Potash (Sodium Hydroxide and Potassium Hydroxide). (2009).

31. IQS . No. 1703, used water in concrete. (2018).

32. ASTM C 494, Standard specification for chemical admixtures for concrete, Am. Soc. Test. Mater.(2017)

33. IQS No.45, Aggregate from natural sources for concrete. and construction, Cent. Organ. Stand. &Quality Control COSQC, Baghdad, 2001, (1984).

34. D. Khale and R. Chaudhary, Mechanism of geopolymerization and factors influencing its development: a review, J. Mater. Sci. 42 (2007) 729–746.

35. D. Hardjito and B. V. Rangan, Development and properties of low-calcium fly ash-based geopolymer concrete, Res. Rep. GC, 94 (2005).

36. N. P. Rajamane and R. Jeyalakshmi, Quantities Of Sodium Hydroxide Solids And Water To Prepare Sodium Hydroxide Solution Of Given Molarity For Geopolymer Concrete Mixes, Indian Concr. Inst. Tech. Pap. (2014) 4–9.

37. Z. Mohammed, T. Al-Attar, and B. Al-Shathr, Effect of Steel Fiber Content on Properties of Fresh Self-compacting Geopolymer Concrete, Eng. Technol. J. 39 (2021) 1875–1881.

38. F. Shahrajabian and K. Behfarnia, The effects of nano particles on freeze and thaw resistance of alkali-activated slag concrete, Constr. Build. Mater., 176 (2018) 172–178.

39. A. AL-Ameeri, The effect of steel fiber on some mechanical properties of self compacting concrete, Am. J. Civ. Eng.1 (2013) 102–110.

40. BS EN 12390‑3:2019, BSI Standards Publication Testing hardened concrete– part 3: Compressive strength of test specimens, Br. Stand. (2019) 18.

41. ASTM C78-02, Standard Test Method for Flexural Strength of Concrete ( Using Simple Beam with Third-Point Loading ) .(2002)1–4.

42. ASTM C642-13, ASTM C642 Standard Test Method for Density , Absorption , and Voids in Hardened Concrete, Am. Soc. Test. Mater. (2013) 4–6.

43. Z. Ge, K. Wang, R. Sun, D. Huang, and Y. Hu, Properties of self-consolidating concrete containing nano-CaCO3, J. Sustain. Cem. Mater. 3 (2014) 191–200.

44. H. Assaedi, The role of nano-CaCO3 in the mechanical performance of polyvinyl alcohol fibre-reinforced geopolymer composites, Compos. Interfaces. 28 (2021) 527–542.

45. E. Rabiaa, R. A. S. Mohamed, W. H. Sofi, and T. A. Tawfik, Developing Geopolymer Concrete Properties by Using Nanomaterials and Steel Fibers, Adv. Mater. Sci. Eng. 2020 (2020).

46. H. Assaedi, F. U. A. Shaikh, and I. M. Low, Effect of nano-clay on mechanical and thermal properties of geopolymer, J. Asian Ceram. Soc. 4 (2016) 19–28.

47. A. Al Ghabban, A. B. Al Zubaidi, M. Jafar, and Z. Fakhri, Effect of Nano SiO2 and Nano CaCO3 on the Mechanical Properties, Durability and flowability of Concrete, IOP Conf. Ser. Mater. Sci. Eng. 454 (2018).

48. F. U. A. Shaikh and S. W. M. Supit, Mechanical and durability properties of high volume fly ash (HVFA) concrete containing calcium carbonate (CaCO3) nanoparticles, Constr. Build. Mater. 70 (2014) 309–321.

49. M. M. Khotbehsara, B. M. Miyandehi, F. Naseri, T. Ozbakkaloglu, F. Jafari, and E. Mohseni, Effect of SnO2, ZrO2, and CaCO3 nanoparticles on water transport and durability properties of self-compacting mortar containing fly ash: Experimental observations and ANFIS predictions, Constr. Build. Mater. 158 (2018) 823–834.

FINANCING

None.

CONFLICT OF INTEREST

None.

AUTHORSHIP CONTRIBUTION

Conceptualization: Eman Hasan Raheem, Haider M.Owaid.

Research: Eman Hasan Raheem, Haider M.Owaid.

Writing - original draft: Eman Hasan Raheem, Haider M.Owaid.

Writing - revision and editing: Eman Hasan Raheem, Haider M.Owaid.