Category: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

Study on the Effects on Self-Compacting Concrete Using Waste Marble Powder and High Volume Calcined Kaolin Clay

Estudio de los Efectos sobre el Hormigón Autocompactante Utilizando Residuos de Polvo de Mármol y Arcilla Caolínica Calcinada de Alto Volumen

Doaa Kadhim Fahad1 *, Haider M. Owaid1 *

1Department of Civil Engineering, College of Engineering, University of Babylon, Babil, Iraq

Cite as: Kadhim Fahad D, Owaid HM. Study on the Effects on Self-Compacting Concrete Using Waste Marble Powder and High Volume Calcined Kaolin Clay. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:836. https://doi.org/10.56294/sctconf2024836

Submitted: 26-01-2024 Revised: 07-04-2024 Accepted: 02-06-2024 Published: 03-06-2024

Editor: Dr.

William Castillo-González ![]()

Note: Paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

This study aims to investigate the influence of pozzolanic materials and waste products on the strength properties of self-compacting concrete (SCC). Specifically, the research uses calcined kaolin clay (CKC) and waste marble powder (WMP), as supplementary materials. The study examines various blending systems, including binary, and ternary mixtures. Test samples were prepared by manipulating the weights of cement components, incorporating CKC, and WMP at different proportions. Fresh properties, such as L-Box, segregation resistance, V-funnel resistance, and slump flow diameter, were evaluated. Hardened properties were assessed at three intervals: 7, 28, and 56 days. The optimal binary mixture demonstrated potential as a substitute for CKC, and WMP improving fresh results and enhancing compressive strength. Ternary blends exhibited higher compressive and tensile strengths. The results indicated that binary blended mixes with 10 % WMP showed enhanced compressive strengths compared to other combinations. Furthermore, the binary blend with 10 % WMP displayed superior compressive strengths at all ages compared to other combinations. Additionally, the ternary blends showcased higher compressive and tensile strengths values, reaching 61,8 MPa, and 4,49 MPa, respectively. The durability performance of the binary and ternary blends SCC is examined in terms of water absorption. In addition, the study successfully met its objectives by lowering the requirement for cement, lowering CO2 emissions, and improving the environmental impact of (SCC). These findings provide valuable insights for the construction industry, promoting the utilization of alternative materials in producing high-performance self-compacting concrete.

Keywords: Calcined Kaolin Clay; Marble Powder; Self Compacting Concrete; Waste Materials.

RESUMEN

El objetivo de este estudio es investigar la influencia de los materiales puzolánicos y los productos de desecho en las propiedades resistentes del hormigón autocompactante (HAC). Específicamente, la investigación utiliza arcilla de caolín calcinada (CKC) y polvo de mármol de desecho (WMP), como materiales suplementarios. El estudio examina varios sistemas de mezcla, incluyendo mezclas binarias y ternarias. Las muestras de prueba se prepararon manipulando los pesos de los componentes del cemento, incorporando CKC y WMP en diferentes proporciones. Se evaluaron las propiedades en fresco, como la caja L, la resistencia a la segregación, la resistencia al túnel en V y el diámetro de flujo de asentamiento. Las propiedades endurecidas se evaluaron en tres intervalos: 7, 28 y 56 días. La mezcla binaria óptima demostró potencial como sustituto del CKC, y el WMP mejoró los resultados en fresco y aumentó la resistencia a la compresión. Las mezclas ternarias mostraron mayores resistencias a la compresión y a la tracción. Los resultados indicaron que las mezclas binarias con un 10 % de WMP mostraron mayores resistencias a la compresión en comparación con otras combinaciones. Además, la mezcla binaria con un 10 % de WMP mostró resistencias a la compresión superiores a todas las edades en comparación con otras combinaciones. Además, las mezclas ternarias mostraron mayores valores de resistencia a la compresión y a la tracción, alcanzando 61,8 MPa y 4,49 MPa, respectivamente. Las prestaciones de durabilidad de las mezclas binarias y ternarias SCC se examinan en términos de absorción de agua. Además, el estudio cumplió con éxito sus objetivos al reducir las necesidades de cemento, disminuir las emisiones de CO2 y mejorar el impacto medioambiental del HAC. Estos resultados proporcionan información valiosa para la industria de la construcción, promoviendo la utilización de materiales alternativos en la producción de hormigón autocompactante de alto rendimiento.

Palabras clave: Arcilla de Caolín Calcinada; Mármol en Polvo; Hormigón Autocompactante; Materiales de Desecho.

INTRODUCTION

Self-Compacting Concrete (SCC) can be made using waste materials. When compared to traditional vibrated concrete, SCC has a higher powder content. When marble is processed, large amounts of waste marble powder are produced, which has a severe effect on the environment. Marble powder (MP) is becoming more and more valued when used as an engineering material in the building industry. Recycling garbage from many industries has positive effects on the environment and the economy. Numerous investigations on SCC made using marble powder have been performed successfully. While the mechanical characteristics dropped, Ilk.er Bekir TopCu et al.(1) showed that a marble dust content of up to 200 kg/m3 had no effect on the workability of fresh SCC. The experimental test results, which were used to prepare different types of cement pastes using marble powder with and without the addition of an acrylic-based super plasticizer, indicated that 10 % replacement of either cement or sand with marble powder caused about 10 to 20 % marginal decrease in compressive strength in late age. This reduction was based on the water-to-cementitious materials ratio. At 28 days of age, the porosity of the water in concrete mixtures containing metakaolin declined marginally in comparison to the reference mixture. Valeria Corinaldesi and colleagues (2010) reference.(2) Ulubeyli and Artirb(3) claim that the application of leftover marble as a fine or coarse aggregate in conventional concrete enhanced the properties of hardened concrete. Furthermore, significant filling rates may now be attained with the development of new generation superplasticizers, guaranteeing complete formwork filling even in circumstances where access is restricted by tiny spaces between reinforcing bars. In (4,5) adding fine materials to SCMs can improve their flowability and stability. Nonetheless, a rise in cement content causes significant increase.

Increase in material costs and frequently causes additional detrimental impacts on the characteristics of concrete, such as increased shrinkage and thermal stress.(6,7) By enhancing the grain-size distribution and particle packing, fine ingredients including fly ash, crushed granulated blast furnace slag, and limestone powder are frequently utilized to increase cohesiveness.(8) Concrete’s mechanical characteristics decreased when waste marble replacement ratios increased in self-compacting concrete. Based on fly ash and sand, Anuj et al.(9) compared MP in SCC to SCC blends. According to Valeria Corinaldes et al.(2), maximum compressive strength was as the primary ingredients of concrete, the coarse and fine aggregate particles themselves must be robust, thus we partially substitute marble powder for cement to achieve high strength. According to (10,11), a binary mixture of Portland cement and marble powder was used in the self-compacting concrete that Aruntas et al.(12) analysed. They found that adding marble powder exacerbated the fresh characteristics of concretes by lengthening the slump flow and V-funnel flow periods and reducing the slump flow diameter. Consequently, a better understanding of the characteristics of concretes or mortars containing marble powder is required. In particular, more research is necessary to remove the negative impacts of marble powder use in ternary cementitious mixes on the initial characteristics of SCC or mortar. In summary, potential benefits in terms of overall environmental impact derived from:

1. Reduced amount of alkaline activator, with its embodied CO2 needed in the formulation;

2. Lower volume of material requiring thermal treatment;

3. Valorization of dimension stone waste streams (marble slurry).

Regarding point (3), we encourage further investigation of this approach using waste from the stone industry other than marble slurry, e.g. granite and dolomite waste, depending on local availability.(13)

Overall, the findings of this study provide valuable insights for the construction industry by promoting the utilization of alternative materials in the production of high-performance self-compacting concrete. These insights contribute to reducing cement consumption, mitigating CO2 emissions, and improving the environmental sustainability of SCC.

Experimental Program

Materials

A Type I Portland cement (PC) was used to produce the plain self-compacting concrete (SCC) mixture. This choice was made due to the alignment of its physical and chemical attributes with the stipulated requirements of the Iraqi standard (IQS No. 5 from 1984).(14) The coarse aggregate used was gravel with nominal maximum size of is 10 mm. As Fine Aggregate, the fineness modulus of fine aggregate measured at 2,31 In accordance with Iraqi standard criteria, this value corresponds to the third gradation zone These values were determined for the gravel as 2,65, 2,58 for the Specific Gravity, 0,94 %, 0,5 % for Absorption, and 0,309 %, 0,03 % for Sulfate Content for fine and coarse aggregate respectively as per IQS NO.45/1984.(15) Admixture for High-Range Water Reduction is a poly carboxylic ether type Superplasticizer (SP) complies with Type F (ASTM C494, 2017).(16) with relative specific gravity of 1,07 was employed to achieve the desired slump flow diameter (700 ± 30 mm) in all concrete mixtures In addition, residual marble powder and Iraqi kaolin clay were utilized for creating metakaolin (MK) or calcined kaolin clay (CKC). Then, to cement by weight in binary, ternary, and quaternary cementitious blends, mineral admixtures were added in various ratios. The PC and mineral admixtures’ physical characteristics and chemical composition are summarised in tables 1 and 2.

|

Tabel 1. Chemical Compositions and Loss on Ignition (LOI) of Kaolin clay (KC) |

|||

|

Chemical composition (%) |

PC |

Kaolin clay |

WMP |

|

(SiO2) |

62,79 |

49,3 |

1,47 |

|

(Al2O3) |

20,58 |

33,8 |

0,84 |

|

(Fe2O3) |

5,60 |

1,43 |

0,34 |

|

(CaO) |

3,28 |

0,71 |

82,1 |

|

(MgO) |

1,94 |

0,57 |

0,40 |

|

(Na2O) |

0,56 |

0,26 |

1,17 |

|

(K2O) |

0,29 |

0,41 |

0,08 |

|

(SO3) |

2,35 |

0,19 |

0,68 |

|

(P2O5) |

0,84 |

0,31 |

0,28 |

|

(TiO2) |

1,94 |

0,52 |

- |

|

(LOI) |

62,79 |

11,73 |

2,83 |

|

Tabel 2. Physical Properties of PLC and MK |

|||

|

Property |

Cement |

CKC |

WMP |

|

Specific gravity |

3,12 |

2,59 |

2,68 |

|

Fineness (Blaine Method), m2/kg |

314 |

1640 |

569 |

|

Median particle size (µm) |

16,8 |

14,3 |

24,8 |

|

Color |

Grey |

Off-White |

Light grey |

Figure 1. WMP used in this study

Figure 2. Calcined clay utilised in this research

Mix Design

In this study, self-compacting concrete mixtures were designed using the European standard (EFNARC, 2005).(17) A constant water/binder (w/b) ratio of 0,38 and a total binder concentration of 496 kg/m3 were the specifications for the raw ingredients utilized to make concrete mixtures. The super plasticizer is added to cement in various amounts 2,5 % (12,4 kg/m3) of cement weight. For the purpose of testing the compressive strength of self-compacting concrete, eight combinations of concrete models with diameters of 10×10×10 cm and 10 diameter × 20 length cm for conducting compressive and splitting tensile strength tests of high-performance made up of two binary mixtures in which calcined clays CKC and marble dust, were used in various ratios to replace cement. three ternary mixtures of 30 % CKC, 10 %WMP, 40 %CKC10WMP and 50 %CKC10 %WMP from the weight of cement.

The mix fraction of the concrete mixture studied is displayed in table 3.

|

Tabel 3. Physical Properties of PLC and MK |

|||||||

|

Mix symbol |

Cement kg/m3 |

Calcined clay kg/m3 |

WMP kg/m3 |

Fine aggregate kg/m3 |

Coarse aggregate kg/m3 |

W/b % |

Super plasticizer % |

|

Control |

496 |

0 |

0 |

835 |

865 |

0,38 |

2,5 |

|

10WMP |

446,4 |

0 |

49,6 |

835 |

865 |

0,38 |

2,5 |

|

30CKC |

347,2 |

148,8 |

0 |

835 |

865 |

0,38 |

2,5 |

|

30CKC10WMP |

297,6 |

148,8 |

49,6 |

835 |

865 |

0,38 |

2,5 |

|

40CKC10WMP |

248 |

198,4 |

49,6 |

835 |

865 |

0,38 |

2,5 |

|

50CKC10WMP |

198,4 |

248 |

49,6 |

835 |

865 |

0,38 |

2,5 |

RESULT AND DISCUSSES

Fresh Properties

To assess the three key flow characteristics - Resistance to segregation, passage capability, and flow and viscosity - of self-compacting concrete (SCC), new tests are required as outlined in EFNARC, 2005.(17) The slump flow test (D (mm)) is conducted to gauge the concrete mixes‘ flow ability.

The determination of whether the consistency standards for fresh concrete specifications are met relies on the results of the first test, the T500 slump flow timing. The V funnel test is utilized to assess the filling capacity of SCC the 2005 European guidelines for self-compacting concrete detail the test method and equipment. SCC concrete is poured into the funnel without applying pressure in this test. The readings from the V-funnel test are reported as the flow time. The L-Box test can be conducted to determine if SCC can pass through reinforcing obstructions without experiencing segregation or blockage. Equipment, test methods, and segregation resistance (stability) can all be evaluated using a stability test with sieves by European standards from 2005. The ability of a new mixture to maintain the initial, largely uniform distribution of constituent materials is referred to as resistance to segregation. The sieve receiver was placed on the weighing machine and its mass (Wp g) was recorded. A sample of (4,8 ± 0,2) kg of concrete was poured from a height of (500 ± 50) mm onto a 5 mm sieve with a diameter of 300 mm, and the actual mass of concrete (WC g) was recorded on the sieve. The concrete was placed in the sieve for (120 ± 5) seconds to allow any laitance or mortar to pass through it while standing on the sieve receiver to compute the segregation index, the weight of the original material on the sieve is divided by the weight of the mortar.

Figure 3. Results of the slump flow diameter test

Figure 4. Test findings for flow diameter over time

Figure 5. Test results for the slump flow time

Figure 6. Test findings for flow diameter over time

Figure 7. Test results for segregation resistance

The slump flow of SCCs mixes had ranged from 810 to 690 mm, the L-Box height ratio from 0,973 to 0,864, and the V-funnel timings (s) from 6,8 to 10,3(s). The slump flow diameters for control mixtures of control – PLC of OPC and 10 %MWP are validated using class three (SF3). 30 %CKC 30 %CKC10 %WMP, 40 %CKC10 % WMP and 50 %CKC10 % WMP are confirmed with class two (SF2). From a filling perspective, all of the mixes are therefore regarded as having good consistency and workability. The EFNARC Guidelines were used to evaluate the workability of each component in the SCC mixes.(17) On the other hand, one characteristic stood out in all SCC blends: the slump values are continuously rising as the WMP replacement ratio is added, as seen in figure 3. All SCCs mixtures’ L-BOX height ratios were verified from the range. The data conformed to the approved SCC reporting requirements as established by EFNARC in 2005.(17)

Funnel flow times (s) were confirmed with class two (VS2). This might be the result of the long, hexagonal plates of calcined kaolin clay being shaped and sized in such a way as to create obstructions in the fresh mixture and increase friction between the particles, as well as the fineness of the CKC particles, which has much higher surface areas that can absorb water, leaving less free water to contribute to flow ability. More water is needed as a result. Others have conducted study and come to the same findings.(4)

Funnel flow times (s) were confirmed with class two (VS2), these results are conforming to acceptable criteria for SCC reported by EFNARC, 2005.(17) The lowest V-funnel times of 10,3 s to 9,5 s as shown figure 2, were measured for the control mixture, straight while the mixtures had the highest slump flow of 810 to 690 mm and 0,868to 0,973 for L-BOX height as shown figure 6. The reason for this could be due to the shape and size of the long, hexagonal plates of calcined kaolin clay particles, which create obstacles in the fresh mix and increase friction between the particles, in addition to the fineness of the particles CKC, which has much higher surface areas absorbing water, leaving less free water to contribute to flow ability. As a result, there is more water demand. The same conclusions have been reached by other researchers.(18)

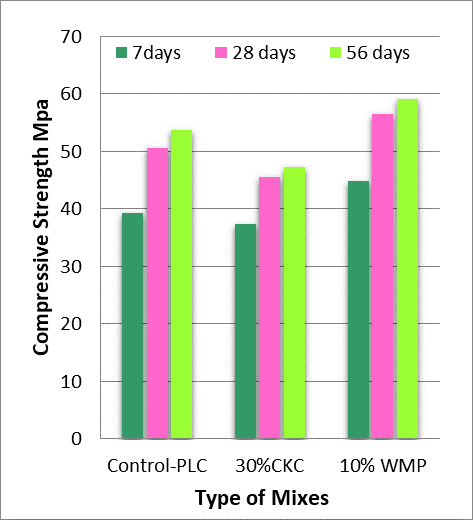

Compressive Strength

The results for concrete compressive strength in addition of metakoline or clinked clay and marble dust with limited replacing of cement. Shown in figure 8, the binary mixtures the compressive strength was reduced of the SCCs with 30 %CKC content while the mix having 10 %WMP replacement of the cement weight to have higher compressive strength comparable with control -PCL the increase ratio was 13,99, 11,66 and 10,03 % at ages 7, 28 and 56 days, respectively. The dilution of the pozzolanic processes may also be the reason for the decrease in the compressive strength of the mortars with CKC. Figure 10 the compressive strength of ternary blends at 7, 28, 56 days of age adding 10 %WMP with 30 %CKC increases ratio of the compressive strength 5,98, 3,06 and 1,47 while adding 10 %MWP with 40 %CKC and 50 %CKC decreases the compressive strength at 7, 28, 56 days of age. the low ratio was 4,84, 4,94 and 6,69 and 8,91, 9,68 and 9,29.

Figure 8. Compressive Strength Results in Binary Blended Mixes of CKC and WMP

Figure 9. The Compressive Strength Results in Ternary Blended Mixes of CKC and WMP

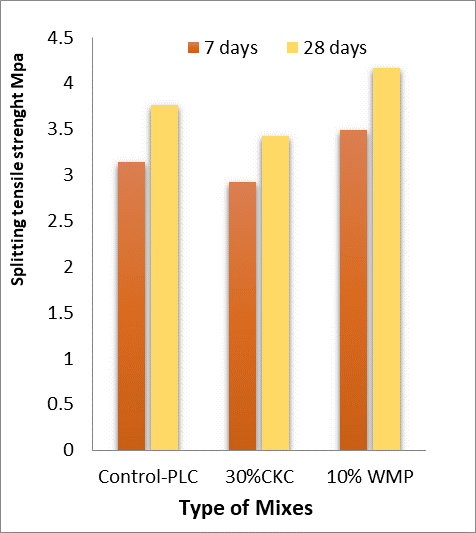

Results for Tensile Strength

(1989) (BS 1881: Part 116) (19) (2000) K.N. a hydraulic compression machine with the compressive strength of cubes (10×10×10cm), was assessed at a loading rate of 18 MPa/minute. An average of three cubes were used for each test, which was carried out after 7, 28, and 56 days. The binary combination in figure 11 When compared to the control –PLC value, 10 %WMP has a greater indirect tensile strength and 30 %CKC has a lower one. Pozzolanic reactions and CKC‘s ability to fill confined areas after interacting with CH to make more C-S-H are the causes. By reducing the concrete‘s porosity and strengthening its microstructure in the ITZ and paste cement matrix, this procedure increases the material‘s tensile strength. Moreover, the calcined kaolin clay‘s vast surface area amplifies a response. These findings are consistent with earlier research.(20,21)

At 7 and 28 days, ternary mixtures with 30 %CKC10 %WMP exceed binary blends with 30 %CKC and the control blend with 100 %OPC. In general, all kinds of binary and ternary blends’ splitting tensile strength. The compressive strengths of SCC mixes that were cured for three to ninety days ranged from 7,4 to 7,92 %, which is less than the results for standard strength concretes, which vary from roughly 8 % to 10 %.(22)

Figure 10. Splitting tensile strength values of binary mixes at 7 and 28 days

Figure 11. Splitting tensile strength values of ternary mixes at 7 and 28 days

Durability Properties of Self-Compacting Concretes

One of the most important characteristics of concrete and mortar is their longevity. Transport characteristics, which are strongly impacted by the pore system, are generally responsible for durability. The durability of the concrete mixes was evaluated by conducting porosity and water absorption tests on samples at 28, and 90 days.

Water Absorption

The two characteristics that can be used to express the water absorption (WA) of concrete are bulk absorption, which is the total amount of water absorbed into an unsaturated sample, and sorptivity, which is the rate at which water is absorbed by capillary suction and can be used as a measure of moisture transport into unsaturated concrete. The amount of water absorbed and the material’s porosity are both influenced by the pore size distribution and capillary pore interconnectivity of concrete.(23)

The water absorption of self-compacting concrete (SCC) is generally less than 5 %.(24) Also, the water absorption is expected to be (3 to 6 %) for SCC.(22) The absorption for binary, and ternary, blended mixes was in the range of 3,28-4,22 %, 3,67-3,98, at 28 days, and 3,01-3,93 %, 3,3-3,82 %, and 3,34-3,82 % at 90 days, respectively. So, all SCCs could be categorized as “high quality”.

Figure 12 shown the increase in (WA) for (30 %CKC) was recorded by about (11,35 %) and (14,6 %), at 28 and 90 days, respectively. This is due to high replacement ratios of CKC. So, there isn’t enough portlandite in the medium for the formation of new CSH gels (less C-S-H) and hydrated calcium aluminates of pozzolan origin, which leads to increased porosity and thus increased water absorption. The finding explained that the replacement of cement by 10 %WMP reduce water absorption. In comparison to the SCPC-PLC mix, the reduction of (WA) was obtained for the SCC, including (10 %WMP) was (10,82 %) and (13,46 %) at the ages of 28 and 90 days, respectively. The results show that adding 10 %WMP had a greater reduction in (WA) than other additions due to the lesser size of particles and effective filling of the voids and gel pores present in the specimen.

In ternary that it was perceived that the decrease in water absorption for ternary mixes (30CKC10 %WMP, 40CKC10 %WMP, 50CKC10 %WMP) was (3,17, 5,01, and 3,69) % and (2,63, 6,12, and 11,37 %) at ages 28 to 90 days, respectively, in comparison to the SCC-PLC mix. These test results showed a considerable improvement in the quality of concrete containing nanoparticles compared with control-PLC and binary blended with CKC at different percentages due to the addition of waste materials and filler improving strength and refinement of pore structure by filling up the minute voids and pores

Figure 12. Water Absorption of Binary Mixes for SCCs Made With CKC, and WMP, at Various Ages

Figure 13. Water Absorption of Ternary Mixes for SCGPCs Made With CKC, and WMPat Various Ages

CONCLUSION

The present study investigated the performance of self-compacting concrete (SCC) incorporating waste materials, namely Waste Marble Powder (WMP) and Limestone Powder (LP), as well as Calcined Kaolin Clay (CKC) as binary and ternary binders. The following key conclusions can be drawn:

1. Binary and ternary blends of waste materials (WMP) with CKC demonstrated successful utilization in the production of self-compacting concrete.

2. Regarding fresh characteristics, the substitution of CKC decreased the slump flow diameter, while replacing WMP in binary blend mixtures increased the slump flow value. Fresh properties were adversely affected by the partial replacement of CKC in binary blends. Ternary blends exhibited more significant effects than binary mixtures, with increased V-funnel time but a continuous decrease in slump flow value. Long, hexagonal plate-shaped CKC particles likely contributed to these results by obstructing the fresh mixture and increasing friction between particles. The irregular or plate-like shape of M.K. particles may have also contributed to reduced slump flow diameter due to decreased mixture expandability. Additionally, the calcined pozzolanic materials’ fineness and higher surface area played a role in these observations.

3. Binary blended SCC mixes with 10 % WMP exhibited improved compressive strengths at all ages, with the most significant impact observed at early curing ages due to the pozzolanic activity of WMP. However, the mixture with 30 % CKC showed a significant decrease in compressive strength compared to other combinations. Ternary mixes containing 30 % CKC with 10 % WMP outperformed binary blends with 30 % CKC and control Portland Limestone Cement (PLC) mix in terms of compressive strength.

4. Splitting Tensile Strength (STS) of SCC mixes generally followed a similar trend to compressive strength, albeit with a slower growth rate. A high volume of CKC resulted in lower levels of Ca(OH)2 generation, which in turn affected the production of C-S-H gel and the density of the interfacial transition zone. As reported in previous studies, this factor influenced tensile strength to a greater extent than compressive strength.

5. For all blended SCC mixtures, the water absorption (WA) values decreased as the curing time decreased.

REFERENCES

1. I.B. Topcu, T. Bilir, T. Uygunoğlu, Effect of waste marble dust content as filler on properties of self-compacting concrete, Constr. Build Mater. 23(5) (2009) 1947-1953.

2. V. Corinaldesi, G. Moriconi, T.R. Naik, Characterization of marble powder for its use in mortar and concrete, Constr. Build Mater. 24(1) (2010) 113-117.

3. G.C. Ulubeyli, R. Artir, Properties of hardened concrete produced by waste marble powder, Procedia Soc. Behav. Sci. 195 (2015) 2181-2190.

4. B. Felekoğlu, S. Türkel, Y. Altuntaş, Effects of steel fiber reinforcement on surface wear resistance of self-compacting repair mortars, Cem. Concr. Compos. 29(5) (2007) 391-396.

5. F. O’Flaherty, P. Mangat, Influence of constituents on the properties of self-compacting repair materials, Proceedings of the first international RILEM symposium, Stockholm, Sweden, 1999, pp. 263-274.

6. Y. Edamatsu, N. Nishida, N. Ouchi, A rational mix-design method for self-compacting concrete considering interaction between coarse aggregate and mortar particles, Proceedings of the 1st International RILEM symposium on self-compacting concrete., Stockholm, Sweden, 1999, pp. 309-320.

7. W. Zhu, J.C. Gibbs, Use of different limestone and chalk powders in self-compacting concrete, Cem. Concr. Res. 35(8) (2005) 1457-1462.

8. M. Sonebi, P. Bartos, Hardened SCC and its bond with reinforcement, Proceeding of First International RILEM Symposium on Self-Compacting Concrete (PRO 7), Stockholm, Sweden, 1999, pp. 275-289.

9. M.M. Anuj, S. Gupta, Rheology of self compacting concrete with marble powder mixes in comparison to fly ash and sand based mixes, IIT Delhi, India, 2015.

10. K. Williams, P. Partheeban, F. Kala, Mechanical properties of high performance concrete incorporating granite powder as fine aggregate, Int. J. Interact. Des. Manuf. Tech. 2(1) (2008) 67-73.

11. B. Soomro, S.A. Mangi, R.A. Bajkani, A.Q. Junejo, Recycling of ceramic tiles and marble powder waste as partial substitution in concrete, Neutron 20(2) (2021) 128-137.

12. H. Aruntas, M. Dayı, I. Tekin, R. Birgul, O. Şimşek, Effects of marble powder on the properties of self-compacting concretes, Proceedings of Second National Symposium on Chemical Admixtures Use in Structures, Ankara, 2007, p. 172.

13. L. Mascarin, H. Ez-zaki, E. Garbin, M. Bediako, L. Valentini, Mitigating the ecological footprint of alkali-activated calcined clays by waste marble addition, Cem. Concr. Compos. 127 (2022) 104382.

14. S. Iraqi, Portland Cement, No. 5, Planning Council (Central Agency for Standardization and Quality Control), Baghdad, Iraq, (1984).

15. S. Iraqi, Aggregate of the Natural Sources Used in Concrete Construction, No. 45, Planning Council (Central Agency for Standardization and Quality Control), Baghdad, Iraq, (1984).

16. A.S.T.M. Standard, C494/C494M-17 Standard Specification for Chemical Admixtures for Concrete, ASTM International, West Conshohocken, PA., (2017).

17. EFNARC, European Guidelines for Self-Compacting Concrete, Specification and Production and Use, Association House, UK, 2005.

18. B.S.C. Kumar, K. Ramesh, Experimental study on strength properties of metakaolin and GGBS based geopolymer concrete, ARPN J. Eng. Appl. Sci. 11(21) (2016) 12414-12422.

19. S. British, Method for determination of compressive strength of concrete cubes, BS 1881: Part 116, British Standard Institutions, London, (1983).

20. V. Kannan, Strength and durability performance of self compacting concrete containing self-combusted rice husk ash and metakaolin, Constr. Build Mater. 160 (2018) 169-179.

21. S. Lenka, K. Panda, Effect of metakaolin on the properties of conventional and self compacting concrete, Adv. Concr. Constr. 5(1) (2017) 031.

22. A.M. Neville, J.J. Brooks, Concrete technology, Person Education, Delhi, India 2003.

23. H.A. Razak, H. Chai, H. Wong, Near surface characteristics of concrete containing supplementary cementing materials, Cem. Concr. Compos. 26(7) (2004) 883-889.

24. S.H. Kosmatka, W.C. Panarese, B. Kerkhoff, Design and control of concrete mixtures, Portland Cement Association, Skokie, Illinois, 2002.

FINANCING

None.

CONFLICT OF INTEREST

None.

AUTHORSHIP CONTRIBUTION

Conceptualization: Doaa Kadhim Fahad, Haider M. Owaid.

Research: Doaa Kadhim Fahad, Haider M. Owaid.

Writing - original draft: Doaa Kadhim Fahad, Haider M. Owaid.

Writing - revision and editing: Doaa Kadhim Fahad, Haider M. Owaid.