Category: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

Optimum Load of the Non-Uniform Heat Flux on Thermoelectric Generator (TEG) with Plate-Pin Heat Sink

Carga óptima del flujo de calor no uniforme en el generador termoeléctrico (TEG) con disipador de calor placa-perno

Huseen S. Yousif1 *, Saad M. JALIL1 *

1University of Anbar, Ramadi, Iraq.

Cite as: Yousif HS, JALIL SM. Optimum Load of the Non-Uniform Heat Flux on Thermoelectric Generator (TEG) with Plate-Pin Heat Sink. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:829. https://doi.org/10.56294/sctconf2024829

Submitted: 23-01-2024 Revised: 05-04-2024 Accepted: 02-06-2024 Published: 03-06-2024

Editor: Dr.

William Castillo-González ![]()

Note: Paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS‘23).

ABSTRACT

The current computational prediction investigated the effect of Non-Uniform Heat Flux (NUHF) patterns on Thermoelectric Generator (TEG) performance. It is studied the impact of changing resistance on the generated power under Uniform Heat Flux (UHF). The dissipated heat from the heat sink of electronic devices (e.g. CPU) through the TEG model, which was heated by NUHF and cooled by convection, was estimated. These devices tend to generate higher heat levels at their core, which gradually decreases toward the boundaries. In order to maintain an appropriate temperature for these electronic parts. A thermoelectric device, which includes a generator, is employed with a pin fin plate heat sink mounted on its back side to dissipate the heat. A numerical simulation was performed to determine the generated power and heat dissipation in the heat sink. When comparing UHF to NUHF, it is clear that the impact on generated electrical power is minimal and can be ignored. In addition, the findings showed that the difference between the NUHF and UHF is negligible and does not exceed 1 %. The power generated in all cases is around 0,1 W and 4,6 W as a heat dissipation. It is found that the optimum load for the current suggested model is 3 Ohm. Also, there is a noticeable enhancement in the generated power by using the suggested heat sink reached up to 30 % compared to the regular one.

Keywords: Thermoelectric Generator; Non-Uniform Heat Flow; Optimum Load For (TEG).

RESUMEN

La presente predicción computacional investigó el efecto de los patrones de Flujo de Calor No Uniforme (NUHF) en el rendimiento del Generador Termoeléctrico (TEG). Se estudia el impacto del cambio de resistencia en la potencia generada bajo Flujo de Calor Uniforme (UHF). Se estimó el calor disipado desde el disipador de calor de los dispositivos electrónicos (por ejemplo, la CPU) a través del modelo de TEG, calentado por NUHF y enfriado por convección. Estos dispositivos tienden a generar mayores niveles de calor en su núcleo, que disminuye gradualmente hacia los límites. Con el fin de mantener una temperatura adecuada para estas piezas electrónicas. Se emplea un dispositivo termoeléctrico, que incluye un generador, con un disipador de calor de placa de aletas montada en su parte posterior para disipar el calor. Se realizó una simulación numérica para determinar la potencia generada y la disipación de calor en el disipador. Al comparar UHF con NUHF, queda claro que el impacto en la potencia eléctrica generada es mínimo y puede ignorarse. Además, los resultados mostraron que la diferencia entre NUHF y UHF es insignificante y no supera el 1 %. La potencia generada en todos los casos es de alrededor de 0,1 W y 4,6 W como disipación de calor. Se comprueba que la carga óptima para el modelo sugerido actualmente es de 3 Ohm. Además, existe una notable mejora en la potencia generada al utilizar el disipador de calor sugerido que alcanza hasta un 30 % en comparación con el disipador normal.

Palabras clave: Generador Termoeléctrico; Flujo de Calor No Uniforme; Carga Óptima Para (TEG).

INTRODUCTION

When electronic devices operate, some electrical energy is stored in the form of heat, which may cause damage to electronic devices. For heat dissipation can be used (TEGs) and convert it into energy that can be used. The power is produced by the Seeback effect. Thermoelectric generator has significant attention as a converter due to its compact design, environment friendly, and noiseless operation process, which are its benefits. The TEG is utilized for cooling (CPUs), and various electronic device Which works with irregular heat flux. Thermoelectric generators also find increasing favor in high-power scenarios, such as air conditioning systems, lighting, and Distributed Generation (DG). An economic estimation has indicated that the (TEG) holds great promise as a technology due to its advantages of minimal operational and maintenance expenses and the absence of moving components.(1) build a TEG model in one dimension that computation for radiative heat removal. Designed model to work with the exhaust gases from a car using a barrel- form heat exchanger showing a shell and straight fin.(2) Analytically investigation of the operational efficiency of a TEG module in relation with an air-cooled heat sink, utilizing two optimization cases. It is eligible to reduce the length of the heat sink by promoting its frontal surface area, as suggested by Young et al.(3) Enhancement the efficiency of power produced in (TEG) by taking into account non-uniform heat distribution include the application of a dedicated system, specifically through the operation of a Maximum Power Point Tracker (MPPT) in linked with blocking diodes.(4) Build a model for the (TEG) unit include the unit display dynamic power modification with sine and triangle waveforms; on average; producing 4,93 % and 2,82 % more than the steady-state; respectively.(5) Ouyang et al. suggested a segmented in their study, featuring a three-dimensional finite element model. In this system, they chosen bismuth telluride for the cold segment and skutterudites materials for the hot segment. Their result indicated that the conversion efficiency with a three-stage thermoelectric module reached 10,52 %.(6) A three-dimensional numerical model was conducted to study the effect of both NUH and UH flow on the operational feature of both segmented and unsegmented (TEGs). The distribution of flux within a parabolic concentrator was determined. The study delved into estimate how load resistance, solar radiation, and cold-side temperature influence the performance of the (TEG)(7), build a model operating with cooling provided by the flow of an Al2O3/water nanofluid across zigzag microchannel heat sinks (ZMCHS), while heat flux is employed to the hot-end. The result show that higher heat flux levels lead to an increase in the efficiency.(8) Meng et al. conducted a study where they developed a model for utilizing automobile exhaust as a heat source and cooling by water as a heat sink to recover waste heat.(9) In this paper, a mathematical model of the Thermoelectric Generators is developed to study how non-uniform heat flux effects its operational efficiency. It was determined that must take into account the effect of irregular heat flux on performance of thermoelectric generators,(10) contrast and examining the thermoelectric generator module‘s dynamic power produced and conversion efficiency under several steady and transient temperature changes. The obtained dynamic response characteristics of the output energy is synchronized with the conversion efficiency.(11) A novel heat sink design called a plate-pin fin heat sink (PPFHS) has been Enhanced by integrating columnar pins in between plate fins within the structure of a classical plate fin heat sink (PFHS). he simulation results indicated that the thermal resistance of a PPFHS was roughly 30 % less than that of a used PFHS.(12) To promote the performance of (TEG) under NUHF which proposed blocking diodes combination with special type of (MPPT). The result show saves power produce by 15 % when used blocking diodes. When used method of (MPPT) increase the power by 20 %.(13) A numerical investigation for cooling process by using nanoparticle in microchannel. The result show enhanced by 10 % at pumping power equal to 2,25 W when comparing water contain nanofluid have diamond (1 vol.%, 2 nm) with water only.(14)

This model was proposed to lower the temperature of electronic devices and recover some of the heat that would alternatively be wasted. The irregular heat flux was applied on hot-end due to the reality that electronic devices product a significant amount of heat concentrated at their center, which then gradually reduction and cooling by convection boundary condition was applied on cold-end. Research was conducted to investigate the effect of NUHF, electrical power generation, find the optimum load, finally show the impact of plate-pin fin heat sink on TEG. Temperature-dependent properties were taken from D. Luo et al.(11)

In summary, the objectives of this paper included:

1. Study the effect of NUHF by comparing it with UHF in term of power output.

2. Finding the optimum external load By studying the change in load with the output. power

3. Comparing the performance of TEG with and without plate-pin fin heat sink.

METHODOLOGY

Model description

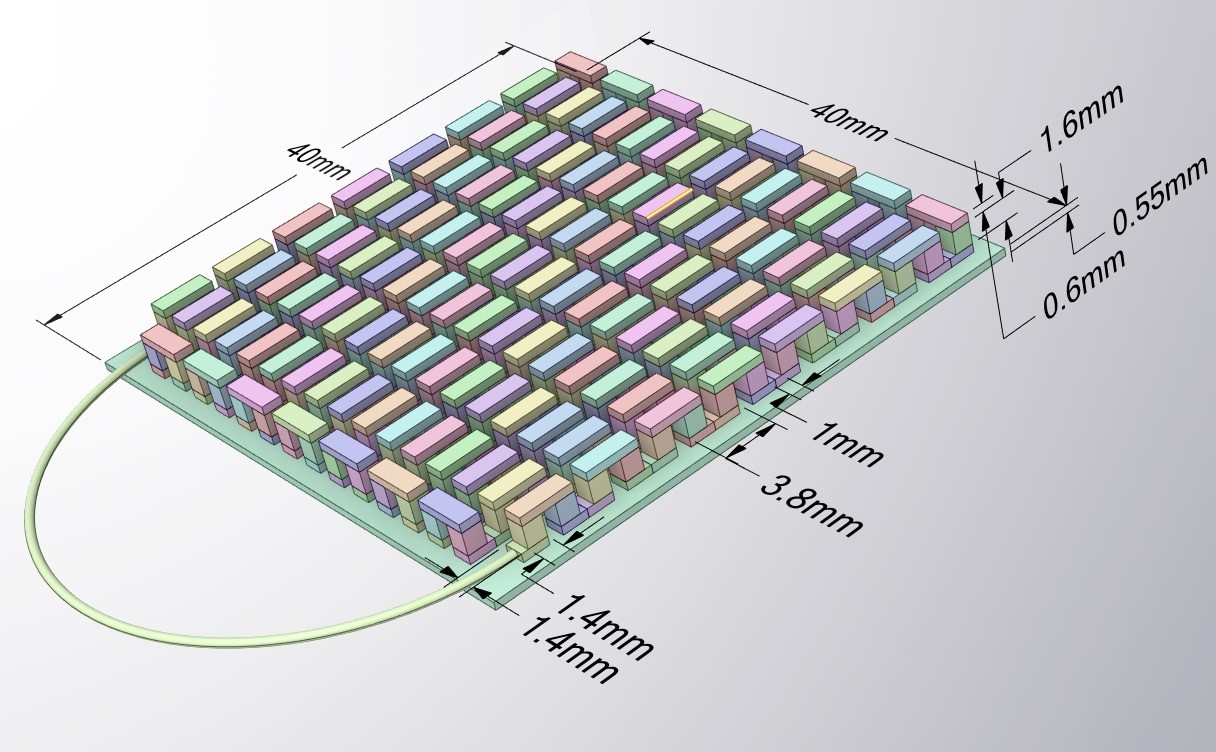

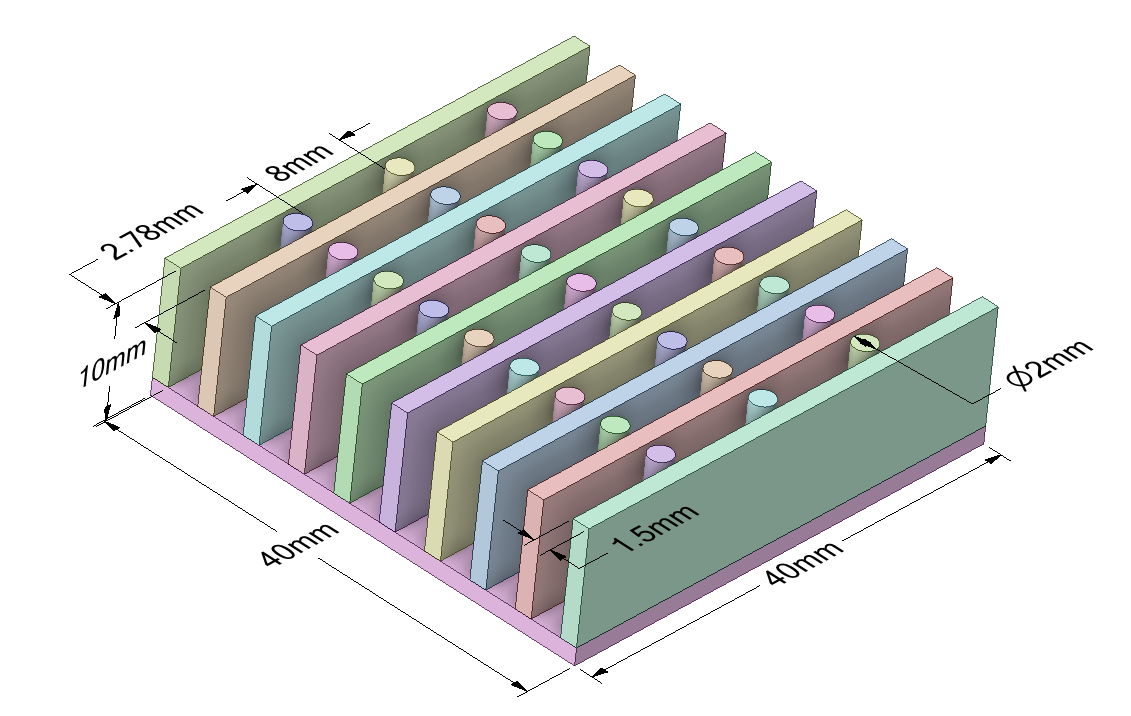

In this study, the TEG model that was constructed as shown in figure 1. The thermoelectric generator is 40 mm × 40 mm ×3,9, Contains ceramic plates, sheets made of copper with the ability to conduct electricity and 127 pairs of positive-negative Legs. The dimensions of the ceramic plate and the copper electrodes thickness is 0,55 mm and 0,6 mm, respectively, and the dimension of positive-negative Legs is 1,4 mm × 1,4 mm × 1,6 mm. A resistor is included in the wire has 54 mm length and 0,6 mm diameter. A plate-pin heat sink is built for cooling at the heat dissipation side and installed on the back of (TEG) shown in figure 2.

Figure 1. Dimension of (TEG) model

Figure 2. Plate-pin fin heat sink

Boundary Conditions

An irregular heat flux was applied on the hot side of TEG Where the highest value is in the center and decreases gradually to the outer edges when the heat generated in electronic devices which in contact with TEG. The hot side was split into certain number of regions from R1 to R10, the first region is central square area is 0,4 by 0,4 centimeter. Subsequent this, each subsequent region is increased by an increment of 0,2 centimeter on each side until reaching the last region as shown in the figure 3. Various heat fluxes are employed in regions to produce the NUHF. The heat flux within the central region R1 is the highest and is referred to as maximum heat flux. The total heat flow input is represented as Q = 16 watts, and figure 3, show the regions of heat flux in this study. In terms of cooling side, convection was used as a boundary condition at a temperature of 295,15 K and the coefficient of convection heat transfer is 10 (w/m* k). It can be considered heat transfer by free convection, since the value is low. The value of heat flux for all cases shown in figure 4. To study the effect of varying resistance on output power, it can be considered the wire as an external load. The range of resistance begins from 1 ohm to 10 ohms has been studied.

Figure 3. Division of regions

Figure 4. Heat flux in different regions

Confirmation of Grid Independence

Investigation of output power across varying number of nodes. This analysis is conducted under certain conditions, involving heat flow at the hot end (16 watt) and convection boundary (T=295,15 K,h=10W/m.K ) It can be considered as heat transfer by free convection. A number of nodes (83831) is chosen to reduce time with good accuracy in result. The figure 5 Shows the mesh generation of TEG model and figure 6. Depicted the optimum of no of nodes which chosen.

Figure 5. Mesh generation of TEG model

Figure 6. Optimum of no of nodes which chosen

Model Validation

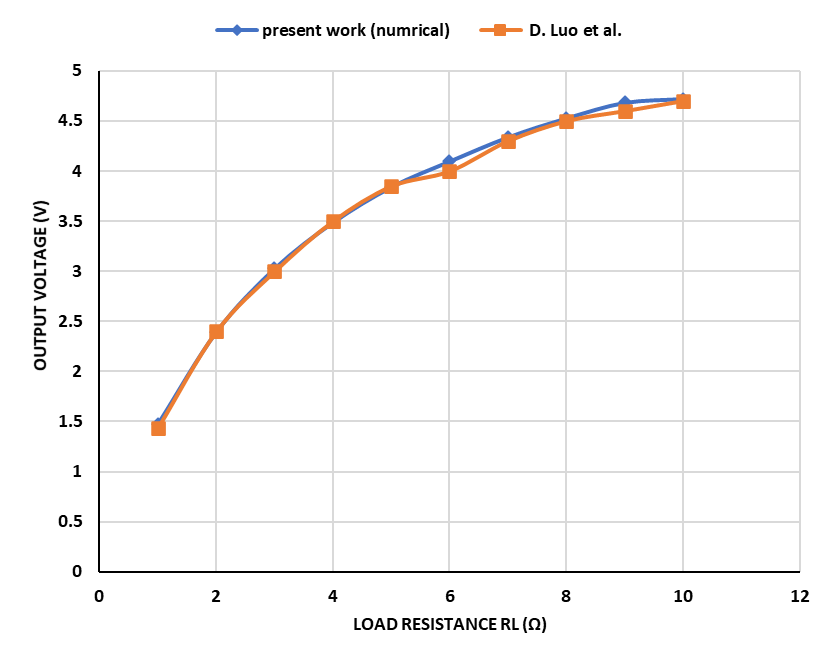

The model was creation based on D. Luo et al.(11) and compered with same reference. while operating at temperature of 450 K on the high-temperature side and 320,2 K on the low-temperature side with varying of resistance value. The maximum error rate observed was 3 %, occurring at a resistance value of 6 ohms as shown in the figure 7.

Figure 7. Model Validation

RESULTS AND DISCUSSIONS

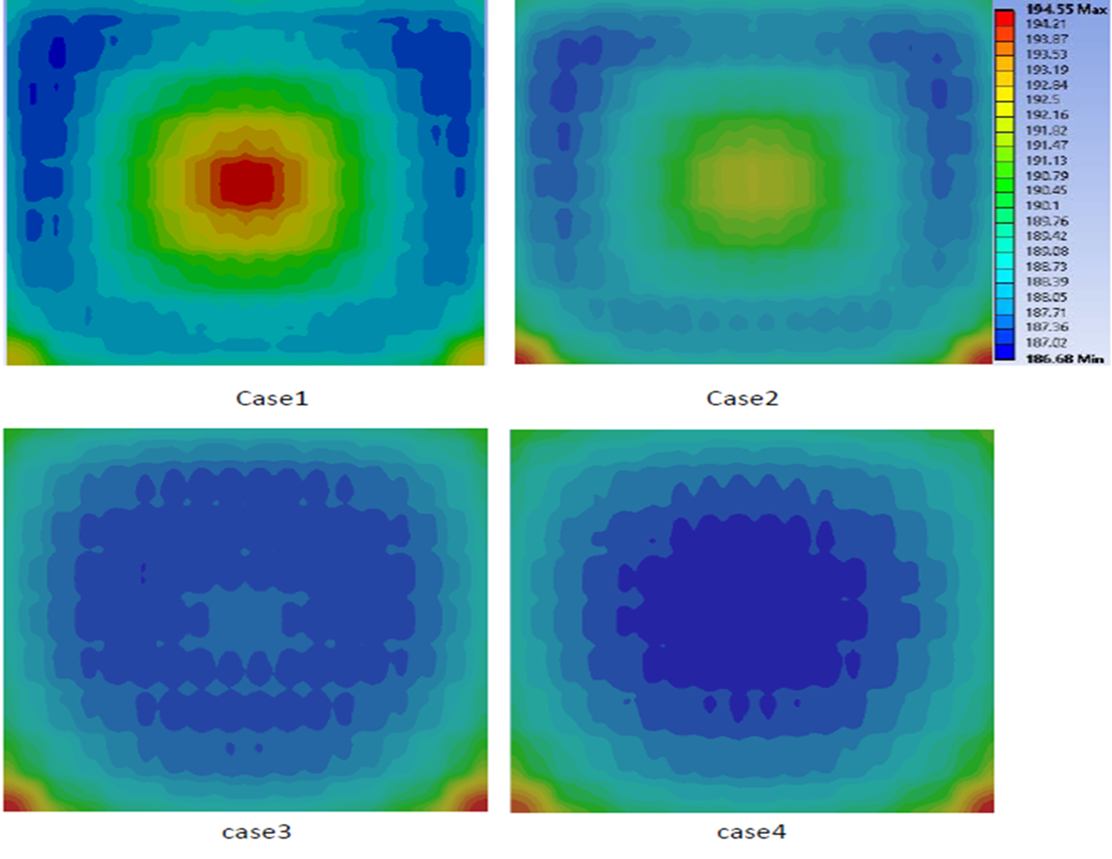

Comparing the temperature distribution of the thermoelectric generator (TEG) under conditions of uniform heat flux (UHF) and non-uniform heat flux (NUHF), as depicted figure 9. the bar temperature in Celsius. When UHF is present, it becomes show that the temperature distribution on the hot side surface. The temperature is lowest at the center and increases towards the edges. The logic for this there is no metal that conducts heat to the cold side at the edges there is no metal that conducts heat to the cold end, Especially the lower part of the surface is completely empty of positive and negative legs. In the first and second cases, heat distribution is concentrated at the center and decrease towards the edges, Since the heat flux in center is very high at these cases. Figure 8 show voltage distribution which connected in series.

Figure 8. Voltage distribution in TEG

Figure 9. Temperature Distribution of (TEG) Surface

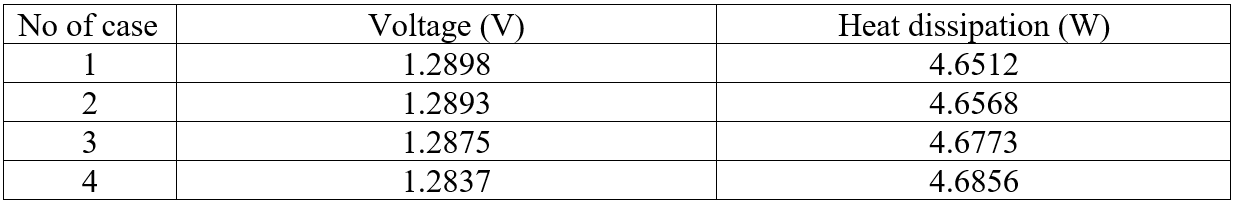

The figure 10 show calculating the heat generated by a thermoelectric generator and the heat dissipated through a heat sink has been estimated for four cases. The results show that the values are very close, and this goes back to the total heat input into the thermoelectric generator is about 16 watts in all cases. The only variation lies in the distribution of heat on the thermoelectric surface, Where the temperature difference of center between UHF and NUHF about 8 Celsius.

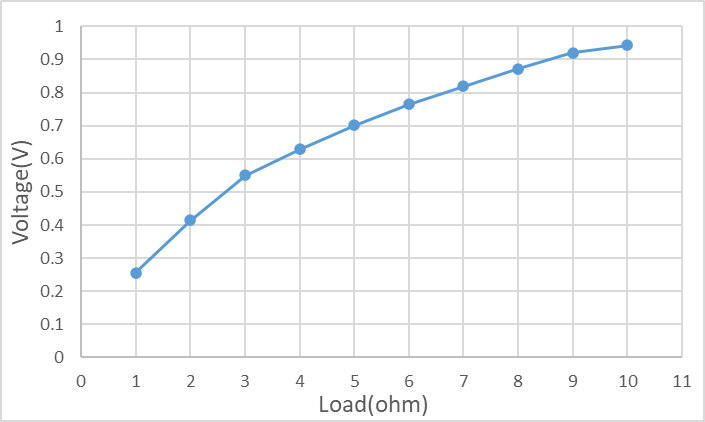

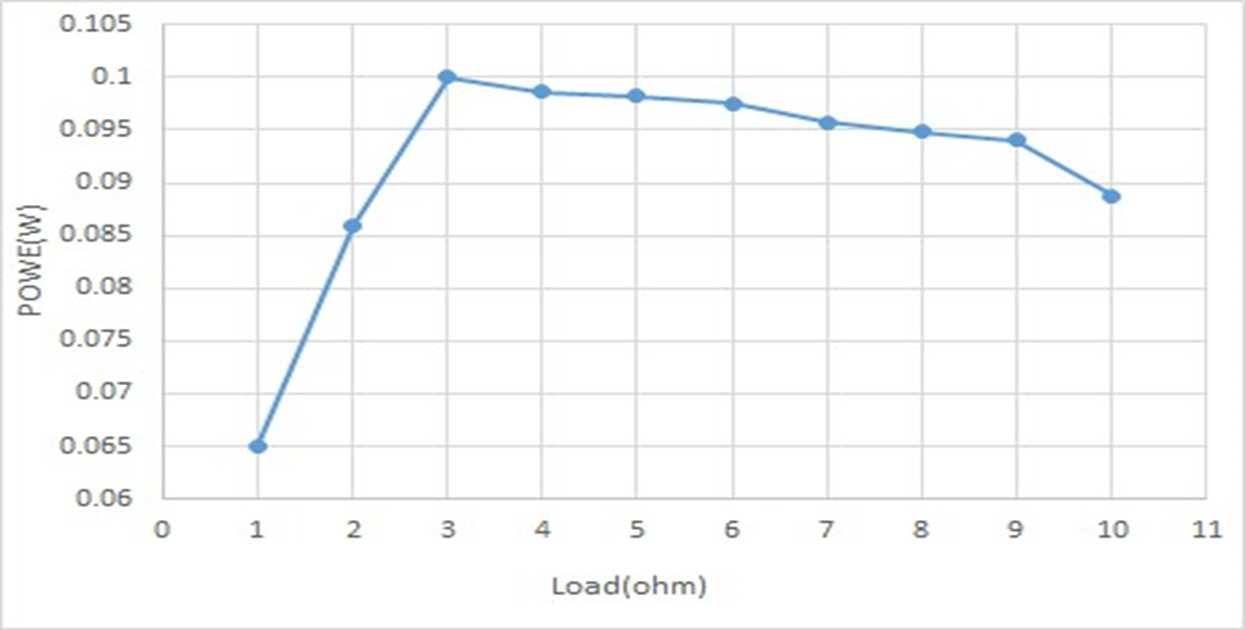

Figure 10. The data collected in the research for open circuit voltage

Figure 11 show the power produce in volt is increase with load resistance increase because when the current is constant and the resistance increase, the same current need more voltage to take the effect of the load resistance increase. Figure 12 show the power produce in watt with load in (ohm) the optimum output power for this model and boundary conditions when load resistance is 3-ohm. Finally, the effect of plate-pin fin heat sink on TEG was studied, and the results showed that using heat sink increases output power and cooling rate by 30 % and 66 % respectively.

Figure 11. The voltage produces (V) with varying load (ohm)

Figure 12. Power produce (W) with varying load (ohm)

CONCLUSIONS

Based on the digital and visible results, it was showed that irregular heat flux has a very slight impact on the overall power produce , which can be neglected the effect of non-uniform heat flux due to The minor deference in the results carried out , as it accounts for less than 1 % of the overall power produced when set side by side with UHF power produced . The small amount of the heat disputed and the produced power is due to The small value of the convection heat transfer coefficient, which is 10 (w/m.k). The heat transfer mode can be considered as free convection heat transfer. Hence, it is suitable to enhance the performance of the entire system should be increase the convection heat transfer coefficient. In figure 11, Power is inversely proportional to resistance and directly proportional to the square power of voltage, and because of the square power, one perfect value seems. The optimum load is 3-ohm and the effect of load must be study when changing the boundary conditions. The results showed that using plate-pin fin heat sink provides good results.

REFERENCES

1. M. L. A. and Z. Leonowicz, “Advanced solar energy systems with thermoelectric generators,” 2018, pp. 1–4.

2. G. C. Kenneth McEnaney, Daniel Kraemer, Zhifeng Ren, “Modeling of concentrating solar thermoelectric generators,” J. Appl. Phys., vol. 110, 2011.

3. Y. G. P. b Young Min Seo a, Man Yeong Ha a, Seong Hyun Park a, Geun Hyung Lee c, Young Soo Kim c, “A numerical study on the performance of the thermoelectric module with different heat sink shapes,” Appl. Therm. Eng. J., vol. 128, pp. 1082–1094, 2018.

4. S. I. Miftah Y. Fauzan , S.M. Muyeen, “Enhanced power extraction from thermoelectric generators considering non-uniform heat distribution,” Energy Convers. Manag., vol. 246, pp. 114–565, 2021.

5. W. Z. a Ding Luo, Yuying Yan, Ruochen Wang, “Numerical investigation on the dynamic response characteristics of a thermoelectric generator module under transient temperature excitations,” Renew. Energy, vol. 170, pp. 811–823, 2021.

6. “design-of-segmented-highperformance-thermoelectric-generators-wi-2018.pdf,” Appl. Energy, vol. 221, pp. 112–121, 2018.

7. Y. C. Samson Shittu, Guiqiang Li, Qindong Xuan, Xudong Zhao, Xiaoli Ma, “Electrical and mechanical analysis ofa segmented solar thermoelectric generator under non-uniform heat flu,” Energy, vol. 199, pp. 117–433, 2020.

8. M. M. Abd El-Samie, M. H. Shedid, and M. A. M. Hassan, “Numerical study of a solar thermoelectric generator with nanofluids based microcooling system,” Numerical Heat Transfer; Part A: Applications, vol. 74, no. 12. pp. 1804–1826, 2018. doi: 10.1080/10407782.2018.1562737.

9. J. H. Meng, X. D. Wang, and W. H. Chen, “Performance investigation and design optimization of a thermoelectric generator applied in automobile exhaust waste heat recovery,” Energy Convers. Manag., vol. 120, pp. 71–80, 2016, doi: 10.1016/j.enconman.2016.04.080.

10. M. Ge, Z. Xuan, G. Zhang, Y. Zhao, and Y. Zhao, “Effect of non-uniform heat flux on solar thermoelectric generator,” Energy Reports, vol. 8, pp. 296–301, 2022, doi: 10.1016/j.egyr.2022.10.253.

11. D. Luo, Y. Yan, R. Wang, and W. Zhou, “Numerical investigation on the dynamic response characteristics of a thermoelectric generator module under transient temperature excitations,” Renew. Energy, vol. 170, pp. 811–823, 2021, doi: 10.1016/j.renene.2021.02.026.

12. X. Yu, J. Feng, Q. Feng, and Q. Wang, “Development of a plate-pin fin heat sink and its performance comparisons with a plate fin heat sink,” Appl. Therm. Eng., vol. 25, no. 2–3, pp. 173–182, 2005, doi: 10.1016/j.applthermaleng.2004.06.016.

13. M. Y. Fauzan, S. M. Muyeen, and S. Islam, “Enhanced power extraction from thermoelectric generators considering non-uniform heat distribution,” Energy Convers. Manag., vol. 246, no. July, p. 114565, 2021, doi: 10.1016/j.enconman.2021.114565.

14. S. P. Jang and S. U. S. Choi, “Cooling performance of a microchannel heat sink with nanofluids,” Appl. Therm. Eng., vol. 26, no. 17–18, pp. 2457–2463, 2006, doi: 10.1016/j.applthermaleng.2006.02.036.

FINANCING

None.

CONFLICT OF INTEREST

None.

AUTHORSHIP CONTRIBUTION

Conceptualization: Huseen S. Yousif, Saad M. JALIL.

Research: Huseen S. Yousif, Saad M. JALIL.

Writing - original draft: Huseen S. Yousif, Saad M. JALIL.

Writing - revision and editing: Huseen S. Yousif, Saad M. JALIL.