Categoría: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

Fabrication and comperization Study the effect of molecular weight for chitosan blended with polyvinyl alcohol for food packaging application

Fabricación y comperización Estudio del efecto del peso molecular del quitosano mezclado con alcohol polivinílico para el envasado de alimentos

Haneen H. Salman1 *, Asra Ali Hussein1 *

1Department of polymer and petrochemical industries, College of Materials Engineering, University of Babylon, Iraq.

Cite as: Salman HH, Hussein AA. Fabrication and comperization Study the effect of molecular weight for chitosan blended with polyvinyl alcohol for food packaging application. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:824. https://doi.org/10.56294/sctconf2024824

Submitted: 21-01-2024 Revised: 01-04-2024 Accepted: 27-05-2024 Published: 28-05-2024

Editor: Dr.

William Castillo-González ![]()

Note: Paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

This research concentrates on the fabrication and characterization of biodegradable food packaging composed of Chitosan and polyvinyl alcohol (PVA), both possessing antioxidant and antibacterial activates. Simultaneously, the aim is to enhance the degradation of food packaging materials, safeguarding the environment against the hazards of pollution caused by food packaging waste, thereby safeguarding human health. The study explores the impact of different molecular weight biopolymers combined with synthetic polymers by incorporating various molecular weights of chitosan and polyvinyl alcohol PVA in different ratios (pure MMW-CS, LMW-Cs, PVA, 70:30, and 90:10). Films were created using the solvent casting method to fabricate and characterize biodegradable food packaging from these biopolymers, aiming to mitigate environmental pollution caused by food packaging waste and its adverse effects on human health. Various tests were conducted, and the comparison between MMW_CS and LMW_Cs revealed that the most effective combination was found to be (pure and 70 % MMW_CS). This combination exhibited superior antibacterial properties, enhanced biofilm formation, favorable contact angle, UV resistance, as well as improved results in AFM and DSC analyses. The chitosan content played a significant role in augmenting the antibacterial activity and reducing roughness in the AFM test. Moreover, chitosan-based films demonstrated exceptional UV absorbance, providing a protective shield against lipid oxidation induced by UV light, thereby preserving the quality of the packaged food.

Keywords: Antimicrobial; Antibacterial; PVA; Chitosan; Molecular Weight; Blend.

RESUMEN

Esta investigación se centra en la fabricación y caracterización de envases biodegradables para alimentos compuestos de quitosano y alcohol polivinílico (PVA), ambos con propiedades antioxidantes y antibacterianas. Simultáneamente, se pretende potenciar la degradación de los materiales de envasado de alimentos, salvaguardando el medio ambiente de los peligros de la contaminación causada por los residuos de envases alimentarios, y salvaguardando así la salud humana. El estudio explora el impacto de diferentes biopolímeros de peso molecular combinados con polímeros sintéticos mediante la incorporación de varios pesos moleculares de quitosano y alcohol polivinílico PVA en diferentes proporciones (MMW-Cs puro, LMW-Cs, PVA, 70:30, y 90:10). Se crearon películas mediante el método de colada con disolvente para fabricar y caracterizar envases alimentarios biodegradables a partir de estos biopolímeros, con el objetivo de mitigar la contaminación ambiental causada por los residuos de envases alimentarios y sus efectos adversos sobre la salud humana. Se realizaron varias pruebas, y la comparación entre MMW_CS y LMW_Cs reveló que la combinación más eficaz resultó ser (puro y 70 % MMW_CS). Esta combinación mostró propiedades antibacterianas superiores, una mayor formación de biopelículas, un ángulo de contacto favorable, resistencia a los rayos UV, así como mejores resultados en los análisis AFM y DSC. El contenido de quitosano desempeñó un papel importante en el aumento de la actividad antibacteriana y la reducción de la rugosidad en la prueba AFM. Además, las películas basadas en quitosano demostraron una excepcional absorbancia UV, proporcionando un escudo protector contra la oxidación lipídica inducida por la luz UV, preservando así la calidad de los alimentos envasados.

Palabras clave: Antimicrobiano; Antibacteriano; PVA; Quitosano; Peso Molecular; Mezcla.

INTRODUCTION

Plastic packaging, typically crafted from nonbiodegradable synthetic materials, plays a vital role in preserving and safeguarding product quality.(1,2) Unfortunately, the widespread improper disposal of these items, combined with the slow degradation of plastic, results in the accumulation of solid waste in the environment.(3) To address these challenges, research into biodegradable polymers has gained momentum. These polymers, derived from renewable sources and posing no toxicity, facilitate composting as a recycling option when packaging reaches the end of its life cycle.(4) Packaging materials serve the crucial function of shielding products, delaying food deterioration, and extending shelf life to enhance overall food quality and safety.(5)

In pursuit of these objectives, various packing materials have been developed, with extensive efforts focused on creating mechanically and functionally effective materials. Notable studies include W. Yang et al.'s exploration of antioxidant and antibacterial lignin nanoparticles in polyvinyl alcohol/chitosan films for active packaging.(6) Patricia Cazón et al. investigated composite films of regenerated cellulose with chitosan and polyvinyl alcohol, emphasizing improved mechanical properties, high water absorption capacity, UV radiation protection, and sufficient transparency.(7) Hossein Haghighi et al. developed eco-friendly antimicrobial films by incorporating ethyl lauroyl arginate (LAE) into chitosan and polyvinyl alcohol, showcasing antibacterial properties.(8)

Beyond material composition, packaging technology is pivotal, with High-Pressure Processing of Foods standing out as a cutting-edge method for ensuring food safety, extending shelf life, and preserving nutrients.(9) Biopolymers, often referred to as biodegradable plastics, undergo a disintegration process involving living organisms.(10) The European Bioplastics Organization defines bioplastics as polymers made from renewable resources or plastics that are compostable and/or biodegradable. These plastics break down under specific conditions, leaving behind no harmful waste.(11,12)

Experimental part

Materials

The materials used to prepare the films were low molecular weight Chitosan (MMW-CS) (50000 - 190000 Da) with viscosity (100 - 300 cps), medium molecular weight Chitosan (190 000 – 310 000 Da) with viscosity (300-1 000 cps) was obtained from Glentham life sciences., Ltd., polyvinyl alcohol (Mw = 85 000 – 1 240 000), glacial acetic acid (Mw = 60,05) was purchased from (Thomas baker chemicals) pvt. ltd. b3 & b4 midc, chemical zone, ambernath 221 501. India , Deionized water.

Preparation of samples

The polymer films were prepared by the casting method, (2 g) of chitosan powder was dissolved in solution consists of (98 %) deionized water and (2 %) of glacial Acetic Acid. The chitosan solution remained of 8 hours under constant stirring at temperature (40 °C). Solution of (5 g) of PVA powder dissolved in 100 ml of deionizad water under constant stirring of 4 hours without heating. The final samples were casted by mixing different proportions of PVA solution (90, 80, 70, 60, 50 wt. %) to the chitosan solution with fixed stirring of 3 hour in order to obtain chitosan/PVA blends. All samples placed in a vacuum of 15 minute to prevent the emergence of air bubbles during casting process and then dried in oven at (40 °C) of 24 hours.

RESULTS AND DISCUSSIONS

Antibactirail test

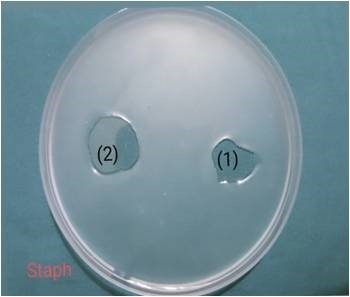

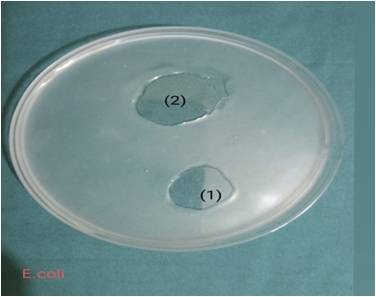

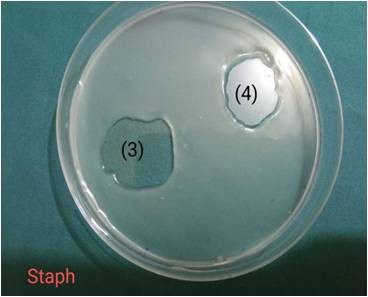

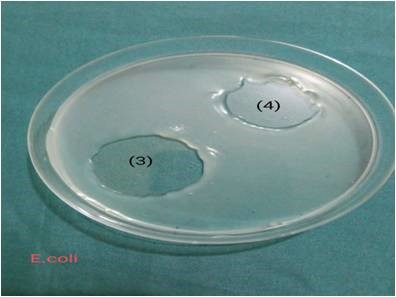

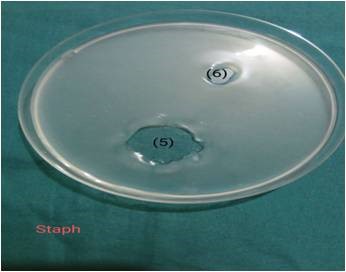

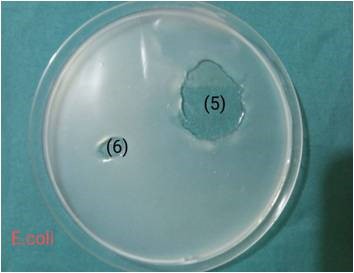

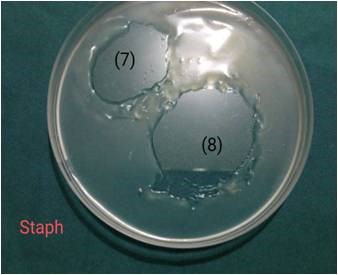

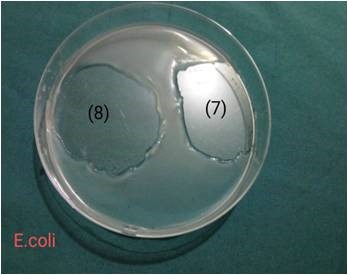

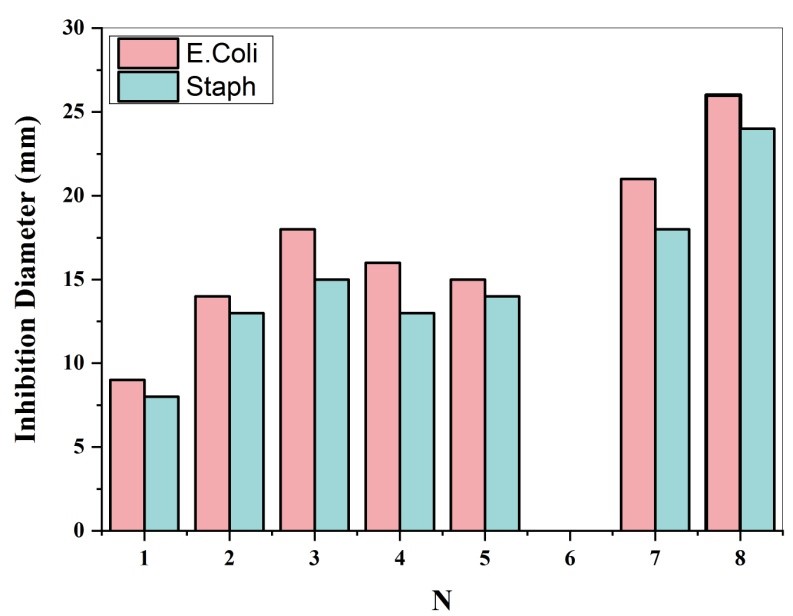

The widely employed Agar well diffusion strategy serves as a common method for evaluating the antimicrobial activity of plant or microbial extracts. As illustrated in figures (1, 2, 3, 4) and the accompanying table 1, it is evident that the higher molecular weight chitosan (MMW-CS) results in an increased inhibition area, proving more effective against both types of bacteria (Gram-positive and Gram-negative) compared to lower molecular weight chitosan (LMW-CS). The antimicrobial nature of chitosan is attributed, in part, to its positively charged amino group, which interacts with the negatively charged cell membranes of microorganisms, leading to the release of proteinaceous and other intracellular constituents.(13)

The inhibitory effect of chitosan on Gram-negative bacteria is marginally higher in comparison to Gram-positive bacteria, as depicted in figure 1-4. This analysis suggests that both pure MMW-CS and the 70 % MMW-CS blend exhibit superior antibacterial properties compared to LMW-CS. It is noteworthy that the antibacterial efficacy of chitosan appears to be closely associated with its molecular weight and degree of acetylation.(14)

|

Table 1. Influencing of chitosan and polyvinyl alcohol for Inhabitation of S. aurous inhabitation of E. coil |

|||

|

No. |

Ratios of chitosan with polyvinyl alcohol |

Inhabitation of S. aurous (mm) |

Inhabitation of E. coil (mm) |

|

1 |

Pure MMW-CS |

24 |

26 |

|

2 |

Pure LMW-CS |

15 |

18 |

|

3 |

PVA 100 % |

0 |

0 |

|

4 |

50 % MMW-CS |

14 |

15 |

|

5 |

70 % MMW-CS |

18 |

21 |

|

6 |

40 % LMW-CS |

8 |

9 |

|

7 |

50 % LMW-CS |

13 |

16 |

|

|

|

|

Figure 1. The impact of (40, 70 wt. %) solution of chitosan low molecular wright on S. aurous bacteria and E.coil bacteria

|

|

|

|

|

|

Figure 2. The impact of (100, 50 wt. %) solution of chitosan low molecular wright on S. aurous bacteria and E.coil bacteria |

|

|

|

|

|

|

Figure 3. The impact of (50, 100 wt. %) solution of chitosan medium molecular wright and polyvinyl alcohol on S. aurous bacteria and E.coil bacteria

|

||

|

|

|

|

|

Figure 4. The impact of (70, 100 wt. %) solution of chitosan medium molecular wright on S. aurous bacteria and E.coil bacteria |

||

Figure 5. The amount of inhibition diameter in mm for both types of Bacteria

Biofilm Formation Assay

Approximately 99 % of bacteria primarily exist as cells attached to surfaces, demonstrating a natural inclination to adhere and form colonies. The adhesion process is significantly influenced by surface properties such as hydrophobicity and the presence of adsorbed polymers.(15) Factors like charge, roughness, energy, stiffness, and topography also play a substantial role in biofilm formation.(16) The findings from this investigation are presented in table 2, indicating that there is minimal adhesion of bacteria to the surface of MMW_CS, resulting in the absence of a biofilm layer. In contrast, weak to moderate adhesion is observed on the surfaces of LMW_CS and PVA, leading to the formation of a biofilm layer. Different proportions of the blend exhibit a medium level of adhesion.

|

Table 2. Biofilm formation of pure MMW-CS, LMW-CS, PVA and the blends |

|||

|

No. |

Samples |

E-Coli |

Staph |

|

1 |

Pure MMW-CS |

Non |

Non |

|

2 |

PVA |

Medium |

medium |

|

3 |

90 % MMW-CS |

Weak |

Weak |

|

4 |

70 % MMW-CS |

Medium |

medium |

|

5 |

Pure LMW-CS |

Weak |

Weak |

|

6 |

90 % LMW-CS |

Medium |

Medium |

|

7 |

70 % LMW-CS |

Medium |

Medium |

UV-Vis spectroscopy

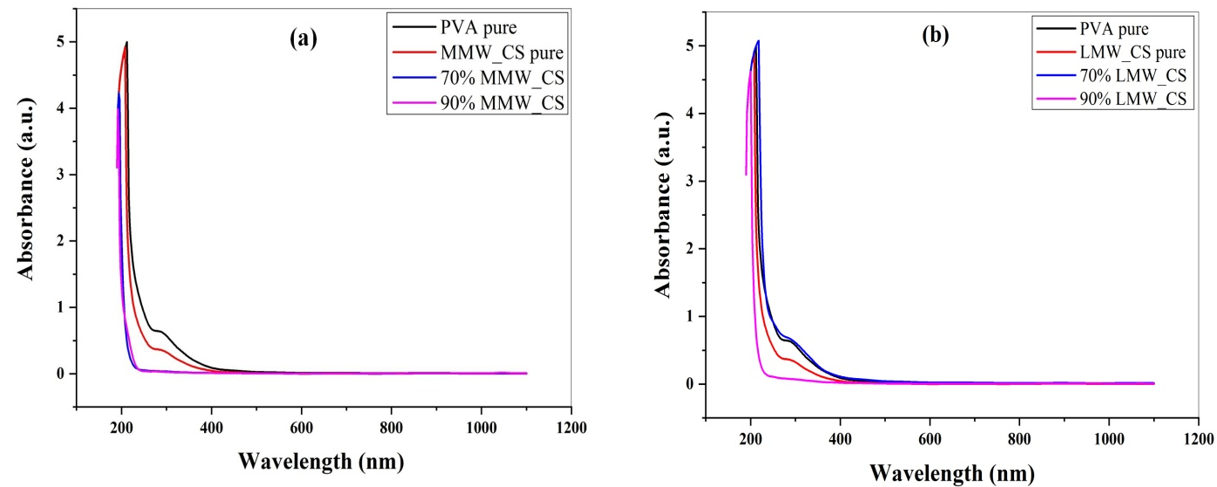

UV-vis spectroscopy is an intriguing technique due to the valuable insights it offers into the absorbance, transmittance, and reflectance of polymeric materials.(17,18,19) Light barrier properties are a sought-after feature in packaging materials as they prevent the oxidation and degradation of nutritional compounds, especially in the presence of UV radiation.(15,16) The recorded UV–Visible spectrum reveals absorption peaks at 208 nm, 214 nm, and 212 nm for MMW_CS, LMW_CS, and PVA, respectively. The introduction of PVA results in a reduction in intensity and broadening of the absorption peak. Notably, Abdelrazek et al. have reported on the analysis of optical properties.(20)

Figure 6. UV–vis spectra for different weight ratios of CH/PVA (a) MMW-CS (b) LMW-CS

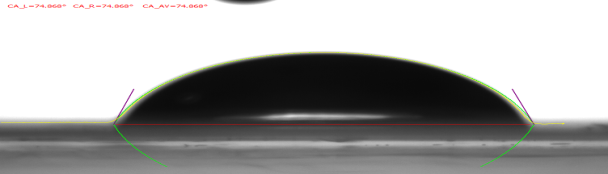

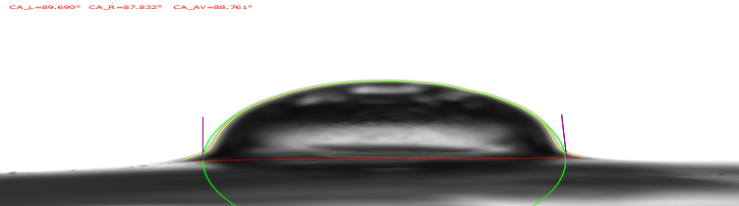

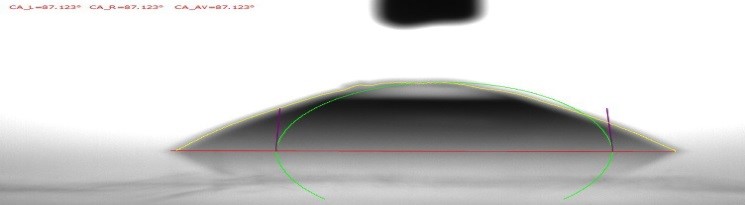

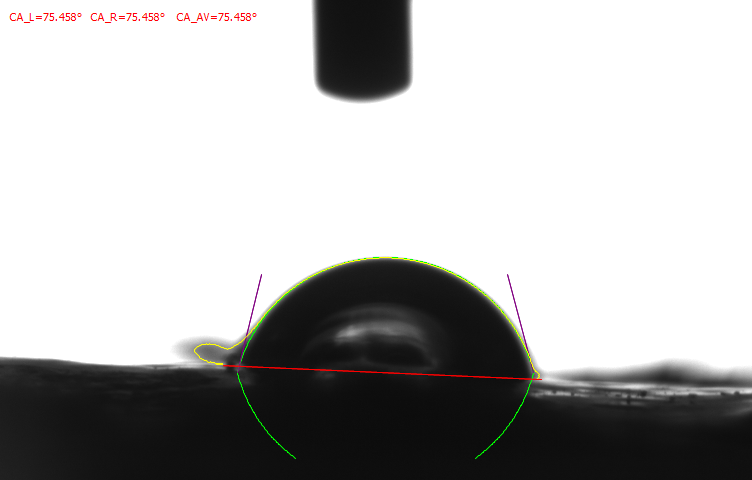

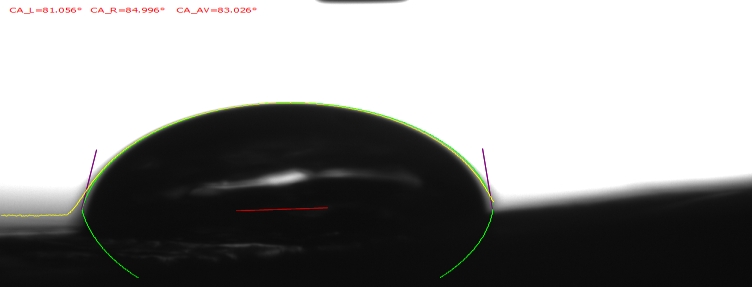

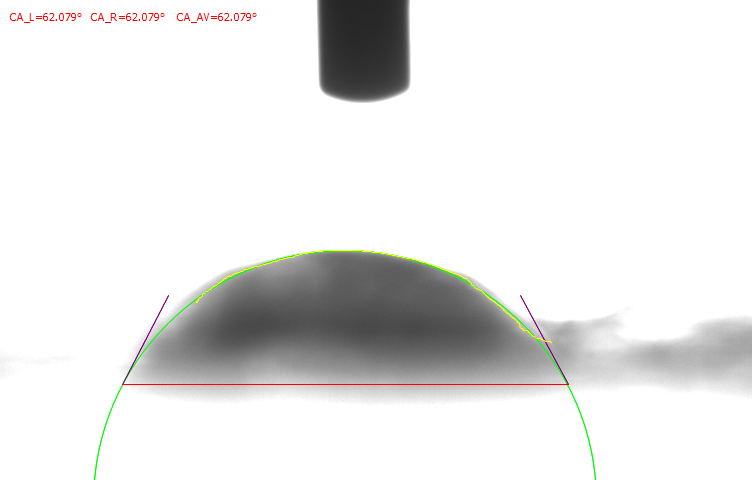

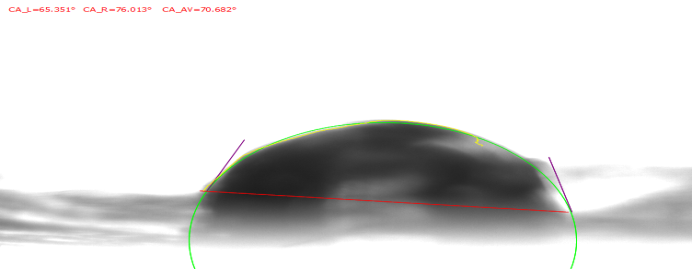

Wettability

An additional crucial aspect of structural analysis for characterizing packaging material involves measuring the water contact angle.(21) In figure 7, a depiction of water droplets on the surfaces of pure CS, PVA, and CS/PVA blend films is presented. Specifically, the contact angle for the pure PVA film is observed to be θ = 74°, indicating a hydrophilic behavior attributed to the presence of hydroxyl groups on the carbon structure.(22,23) Similarly, both MMW-CS and LMW-CS exhibit a hydrophilic nature due to the presence of hydrophilic amino and hydroxyl groups in the CS chain. This aligns with research findings by Chiu and colleagues, (24) who reported that in blends of CS/PVA with increased PVA content, the contact angle decreases. This outcome is consistent for both medium and low types of chitosan.

|

Pure PVA |

|

|

Pure MMW-CS |

|

|

Pure LMW-CS |

|

|

70 % MMW-CS |

|

|

90 % MMW-CS |

|

|

70 % LMW-CS |

|

|

90 % LMW-CS |

|

|

Figure 7. Contact angles of pure PVA, MMW-CS, LMW-CS and its blend |

|

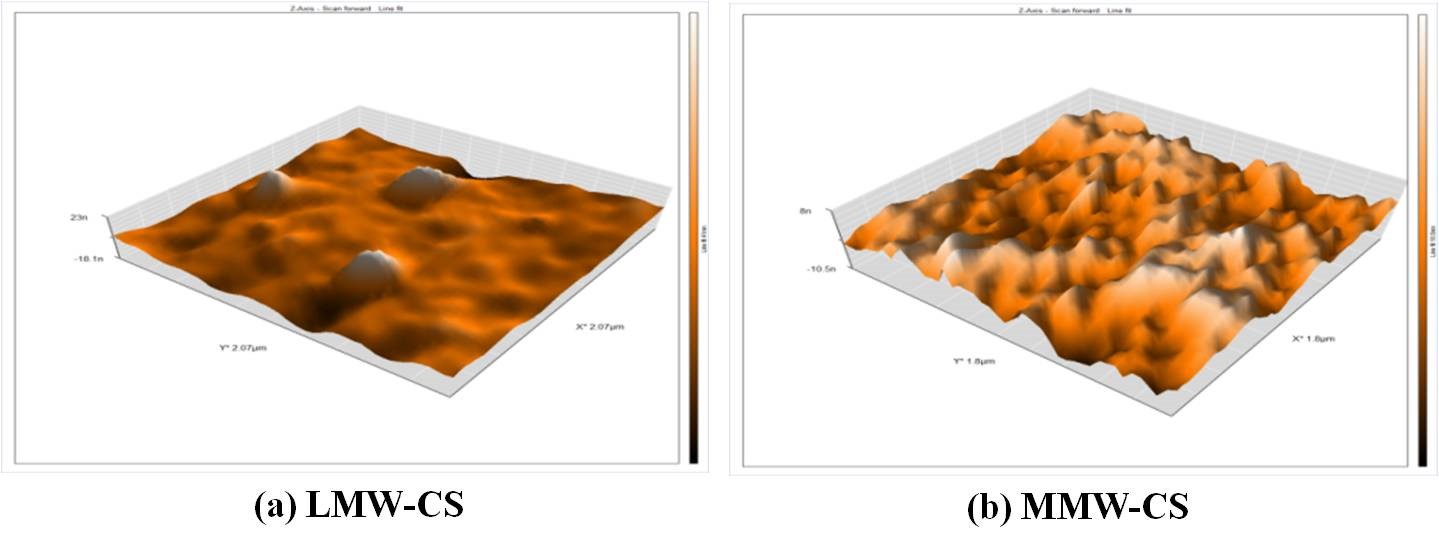

Atomic force microscopy (AFM)

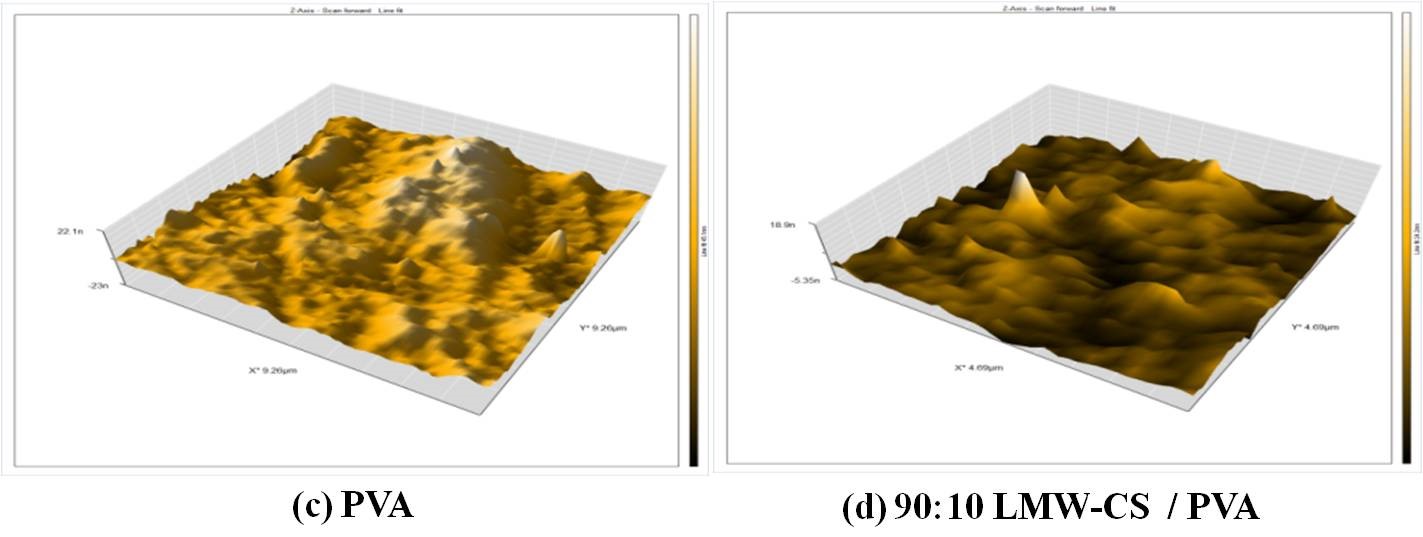

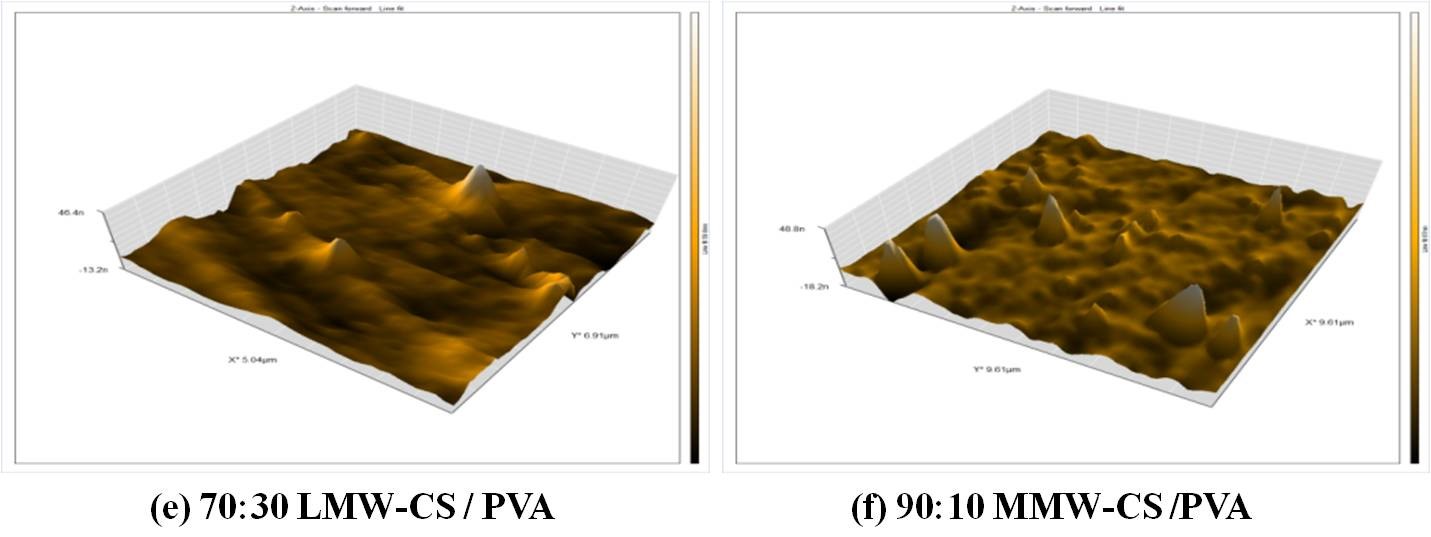

AFM provides intricate details regarding alterations in surface roughness. As evidenced by the provided table 3, the surface of medium molecular weight (Mw) chitosan appears smoother than that of low molecular weight (Mw) chitosan. In the case of pure PVA, a consistently smooth surface layer is achieved, with a film roughness measuring 8nm, a finding consistent with prior research.(25) Altering the ratio in the CS/PVA blend demonstrates that the roughness increases as the chitosan ratio decreases for both types, as indicated in the table. Clearly, the film surface roughness experiences a significant increase with a reduced ratio of chitosan.

|

Table 3. The root-mean-square (RMS) roughness of pure LMW-CS, MMW-CS, PVA and blends 70, 90 %. |

||

|

No. |

Sample |

RMS (nm) |

|

1 |

Pure LMW-CS |

12,461 |

|

2 |

Pure MMW-CS |

4,4837 |

|

3 |

Pure PVA |

8,2168 |

|

4 |

90 % MMW-CS |

5,8705 |

|

5 |

70 % MMW-CS |

12,689 |

|

6 |

90 % LMW-CS |

8,8246 |

|

7 |

70 % LMW-CS |

19,629 |

|

|

|

|

|

|

|

|

|

Figure 8. The 3D AFM images of pure PVA, MMW-CS, LMW-CS and the blend (70, 90 % of MMW-CS, LMW-CS) |

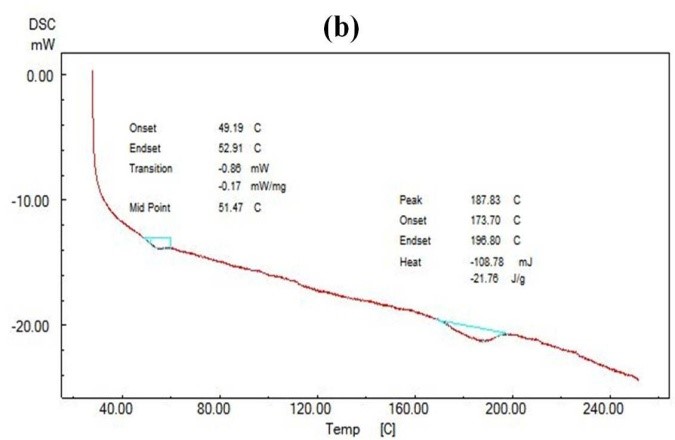

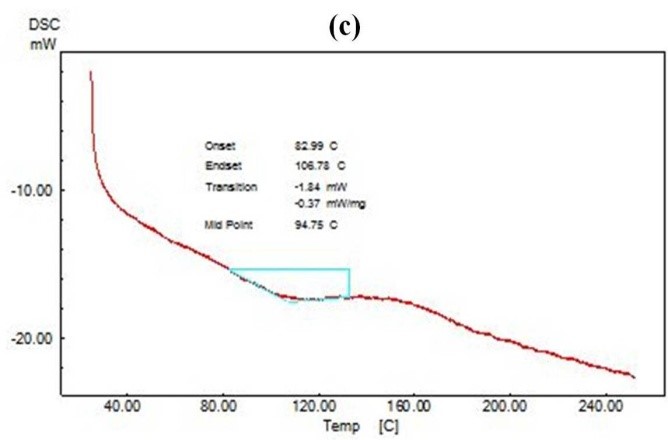

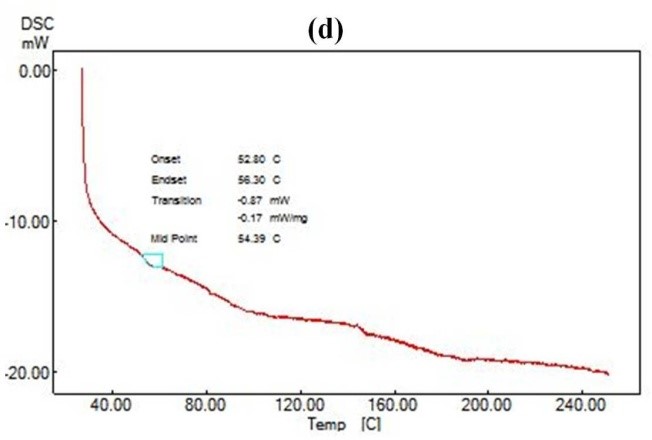

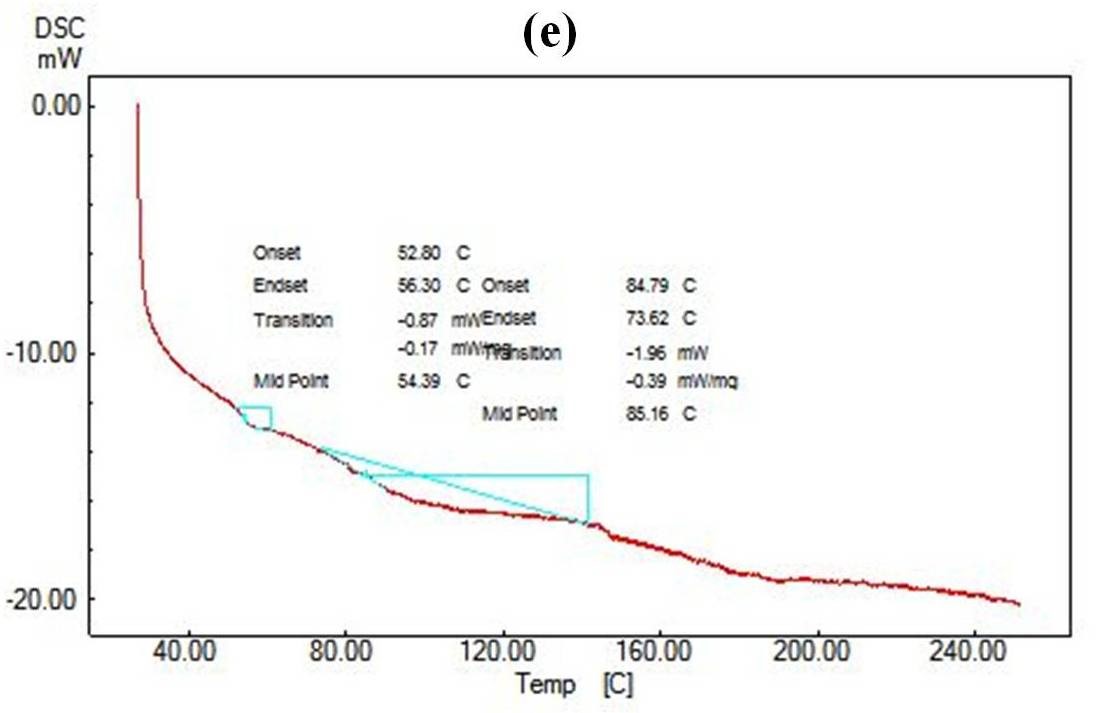

Differential scanning calorimetry (DSC)

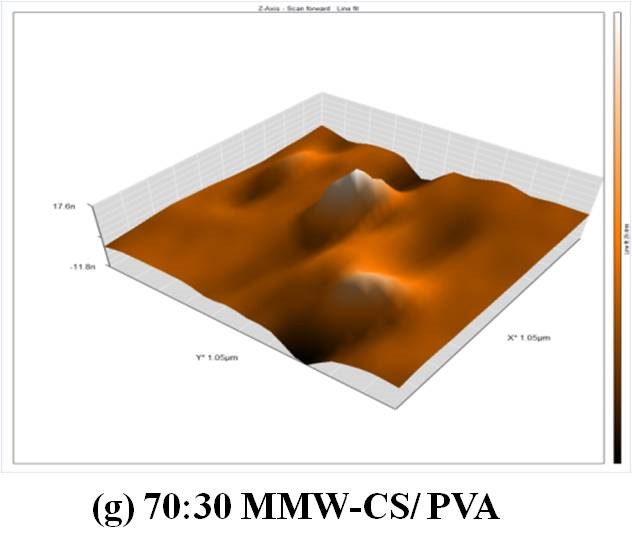

The DSC curves offer insights into the blend's component miscibility, revealing changes in Tm and Tg concerning composition.(26) Figure 9 displays DSC curves for the blended CS/PVA films alongside their pure CS and PVA counterparts. Notably, the DSC curve of the chitosan film exhibits a broad endothermic peak at approximately 87,93 °C, representing the evaporation of absorbed water molecules in the CS molecule and signifying the energy required for water vaporization within the film. Conversely, the PVA film displays a smaller endothermic peak around 51,47 oC. At 70 % Mmw-Cs, broad endothermic peaks appear at higher positions compared to the pure components, within the range of 94,75 oC. Conversely, at 70 % Lmw-Cs, two distinct phases manifest at (54,39 & 85,16), indicating immiscibility and a lack of interaction between the components. At 90 % Mmw-Cs, broad endothermic peaks emerge at lower positions than the pure components, registering at 54,39 °C.

|

|

|

|

|

|

|

|

|

|

Figure 9. DSC curves of (a) pure MMW-CS, (b) pure PVA, (c) 70 % MMW-CS, (d) 90 % MMW-CS, (e) 70 % LMW-CS |

|

CONCLUSION

The current study involved the fabrication of biodegradable films using both MMW-CS and LMW-CS combined with PVA. The outcomes suggest that the blending of chitosan and PVA, achieved through the casting technique during the CS-PVA blending process, results in effective polymer interaction. Antibacterial assessments reveal that higher chitosan content correlates with increased inhibition diameter, with the optimal percentages observed in pure and 70 % MMW-CS. This trend is further evident in biofilm formation assays.

Wettability tests indicate that both PVA and CS polymers exhibit hydrophilic characteristics. The AFM examination demonstrates that an elevated proportion of CS leads to decreased surface roughness, inhibiting bacterial growth. The films exhibit robust barrier properties against UV radiation, with diminishing intensity. This attenuation proves beneficial in averting lipid oxidation processes in food. In summary, our research and conducted tests highlight the superiority of MMW-CS over LMW-CS as a viable alternative to synthetic films. The findings suggest the feasibility of producing films with favorable properties suitable for food packaging.

REFERENCES

1. Swapna Joseph, C., Harish Prashanth, K. V., Rastogi, N. K., Indiramma, A. R., Yella Reddy, S., & Raghavarao, K. S. M. S. (2011). Optimum blend of chitosan and poly-(ε-caprolactone) for fabrication of films for food packaging applications. Food and Bioprocess Technology, 4, 1179-1185.

2. Landim, A. P. M., Bernardo, C. O., Martins, I. B. A., Francisco, M. R., Santos, M. B., & Melo, N. R. D. (2016). Sustainability concerning food packaging in Brazil. Polímeros, 26, 82-92.

3. Fathima, P. E., Panda, S. K., Ashraf, P. M., Varghese, T. O., & Bindu, J. (2018). Polylactic acid/chitosan films for packaging of Indian white prawn (Fenneropenaeus indicus). International Journal of Biological Macromolecules, 117, 1002-1010>

4. Gutiérrez, Tomy J., Julieta R. Mendieta, and Rodrigo Ortega-Toro. "In-depth study from gluten/PCL-based food packaging films obtained under reactive extrusion conditions using chrome octanoate as a potential food grade catalyst." Food Hydrocolloids 111 (2021): 106255.

5. Zhang, Hongkang, and Gauri Mittal. "Biodegradable protein‐based films from plant resources: A review." Environmental progress & sustainable energy 29.2 (2010): 203-220.

6. Yang, W., Owczarek, J. S., Fortunati, E., Kozanecki, M., Mazzaglia, A., Balestra, G. M., ... & Puglia, D. (2016). Antioxidant and antibacterial lignin nanoparticles in polyvinyl alcohol/chitosan films for active packaging. Industrial crops and products, 94, 800-811.

7. CAZÓN, Patricia; VÁZQUEZ, Manuel; VELAZQUEZ, Gonzalo. Composite films of regenerate cellulose with chitosan and polyvinyl alcohol: Evaluation of water adsorption, mechanical and optical properties. International Journal of Biological Macromolecules, 2018, 117: 235-246.

8. Haghighi, H., Leugoue, S. K., Pfeifer, F., Siesler, H. W., Licciardello, F., Fava, P., & Pulvirenti, A. (2020). Development of antimicrobial films based on chitosan-polyvinyl alcohol blend enriched with ethyl lauroyl arginate (LAE) for food packaging applications. Food Hydrocolloids, 100, 105419.

9. Koutchma, T., Song, Y., Setikaite, I., Juliano, P., BARBOSA‐CÁNOVAS, G. V., Dunne, C. P., & Patazca, E. (2010). Packaging evaluation for high‐pressure high‐temperature sterilization of shelf‐stable foods. Journal of food process engineering, 33(6), 1097-1114.

10. Peelman, N., Ragaert, P., De Meulenaer, B., Adons, D., Peeters, R., Cardon, L.,Van Impe, F., Devlieghere, F. Application of bioplastics for food packaging.Trends in Food Science and Technology 32:128–141, 2013.

11. Chandra, R. U. S. T. G. I., and Renu Rustgi. "Biodegradable polymers." Progress in polymer science 23.7 (1998): 1273-1335.

12. Reddy, M. M., Vivekanandhan, S., Misra, M., Bhatia, S. K., & Mohanty, A. K. (2013). Biobased plastics and bionanocomposites: Current status and future opportunities. Progress in polymer science, 38(10-11), 1653-1689.

13. Shahidi, Fereidoon, Janak Kamil Vidana Arachchi, and You-Jin Jeon. "Food applications of chitin and chitosans." Trends in food science & technology 10.2 (1999): 37-51.

14. H.W. Lee, Y.S. Park, J.S. Jung, W.S. Shin, Anaerobe 8 (6) (2002) 319.

15. Costerton JW, Cheng KJ, Geesey GG, Ladd TI, Nickel JC, Dasgupta M, et al. Bacterial biofilms in nature and disease. Annu Rev Microbiol 1987;41:435–64

16. Song F, Koo H, Ren D. Effects of material properties on bacterial adhesion and biofilm formation. J Dent Res 2015;94:1027–34

17. Deshmukh, S.H.; Burghate, D.K.; Shilaska, S.N.; Deshmukh, P.T. Optical properties of polyaniline doped PVC-PMMA thin films. Ind. J. Pure Appl. Phys. 2008, 46, 344–348. A. Silva-Weiss, M. Ihl, P.J.A. Sobral, M.C. Gómez-Guillén, V. Bifani, Natural additives in bioactive edible films and coatings: functionality and applications in foods, Food Eng. Rev. 5 (2013) 200–216

18. R. Kanatt, M.S. Rao, S.P. Chawla, A. Sharma, Active chitosan–polyvinyl alcohol films with natural extracts, Food Hydrocoll. 29 (2012) 290–297.

19. E.M. Abdelrazek, I.S. Elashmawi, S. Labeeb, Chitosan filler effects on the experimen- tal characterization, spectroscopic investigation and thermal studies of PVA/PVP blend films, Phys. B Condens. Matter 405 (2010) 2021–2027.

20. Calderón-Aguirre, Á.-G., Chavarría-Hernández, N., Mendoza-Mendoza, B., Vargas-Torres, A., García-Hernández, E., & Rodríguez-Hernández, A.-I. Antilisterial activity and physical- mechanical properties of bioactive caseinate films. CyTA-Journal of Food, (2015). 13(4), 483-490.

21. Qiu K., Netravali A.N. A Composting Study of Membrane-Like Polyvinyl Alcohol Based Resins and Nanocomposites. J. Polym. Environ. 2013;21:658–674. doi: 10.1007/s10924-013-0584-0.

22. Cho D., Netravali A.N., Joo Y.L. Mechanical properties and biodegradability of electrospun soy protein Isolate/PVA hybrid nanofibers. Polym. Degrad. Stab. 2012;97:747–754. doi: 10.1016/j.polymdegradstab.2012.02.007.

23. Chuang, Wen-Yuan, et al. "Properties of the poly (vinyl alcohol)/chitosan blend and its effect on the culture of fibroblast in vitro." Biomaterials 20.16 (1999): 1479-1487.

24. Suganthi, Sanjeevamuthu, et al. "Fabrication of PVA polymer films with improved antibacterial activity by fine-tuning via organic acids for food packaging applications." Applied Water Science 10.4 (2020): 1-11.

25. Pawar, Vaishali, and Rohit Srivastava. "Chitosan-polycaprolactone blend sponges for management of chronic osteomyelitis: A preliminary characterization and in vitro evaluation." International Journal of Pharmaceutics 568 (2019): 118553.

FINANCING

"The authors did not receive financing for the development of this research".

CONFLICT OF INTEREST

"The authors declare that there is no conflict of interest".

AUTHORSHIP CONTRIBUTION

Conceptualization: Haneen H. Salman, Asra Ali Hussein.

Data curation: Haneen H. Salman, Asra Ali Hussein.

Formal analysis: Haneen H. Salman, Asra Ali Hussein.

Research: Haneen H. Salman, Asra Ali Hussein.

Methodology: Haneen H. Salman, Asra Ali Hussein.

Drafting - original draft: Haneen H. Salman, Asra Ali Hussein.

Writing - proofreading and editing: Haneen H. Salman, Asra Ali Hussein.