Category: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

Impact of new type of plastic as aggregate on fresh and hardened, microstructure properties of concrete

Impacto de un nuevo tipo de plástico como árido en las propiedades microestructurales del hormigón fresco y endurecido

Abeer Muayad Saleh1 *, Sheelan Mahmoud Hama1 *

1Department of Civil Engineering, College of Engineering, University Of Anbar, Iraq.

Cite as: Muayad Saleh A, Mahmoud Hama S. Impact of new type of plastic as aggregate on fresh and hardened, microstructure properties of concrete. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:815. https://doi.org/10.56294/sctconf2024815

Submitted: 19-01-2024 Revised: 02-04-2024 Accepted: 01-06-2024 Published: 02-06-2024

Editor: Dr.

William Castillo-González ![]()

Note: Paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

The goal of this work is to reuse plastic waste as a result of the production of valves on gas bottles into concrete. In this way, one can reduce and consume that waste and at the same time reuse it in concrete and study its effects on its properties to decide which best content. This kind of plastic waste was used in different quantities (5 %, 7,5 %, 10 %, 12,5 %, and 15 %) to replace fine natural aggregate (sand) partially. The effects of these ratios on the fresh concrete’s slump factor, the density of hardened concrete, compressive strength, absorption, microstructure, and ultrasonic pulse speed were studied and compared with a reference mixture free of plastic waste. The ANOVA analysis was used to analyze the results of the fresh and hardened tests, and it was concluded that 5 % was the ideal percentage of the percentages used, as it had less negative influence on the properties of concrete. From laboratory work, it was concluded that increasing the percentage of plastic waste has a negative impact on the properties of concrete, such as reducing compressive strength, flexural strength, spitting tensile strength, and increasing absorption.

Keywords: Waste plastic; Strength; ANOVA; Microstructure.

Resumen. El objetivo de este trabajo es reutilizar en hormigón los residuos plásticos resultantes de la fabricación de válvulas en botellas de gas. De esta manera, se puede reducir y consumir ese residuo y al mismo tiempo reutilizarlo en hormigón y estudiar sus efectos sobre sus propiedades para decidir cuál es el mejor contenido. Este tipo de residuos plásticos se utilizó en diferentes cantidades (5 %, 7,5 %, 10 %, 12,5 % y 15 %) para sustituir parcialmente al árido fino natural (arena). Se estudiaron los efectos de estas proporciones sobre el factor de asentamiento del hormigón fresco, la densidad del hormigón endurecido, la resistencia a la compresión, la absorción, la microestructura y la velocidad de los impulsos ultrasónicos, y se compararon con una mezcla de referencia sin residuos plásticos. Se utilizó el análisis ANOVA para analizar los resultados de las pruebas en fresco y endurecido, y se concluyó que el 5 % era el porcentaje ideal de los utilizados, ya que tenía menos influencia negativa en las propiedades del hormigón. A partir del trabajo de laboratorio, se concluyó que el aumento del porcentaje de residuos plásticos tiene un impacto negativo en las propiedades del hormigón, como la reducción de la resistencia a la compresión, la resistencia a la flexión, la resistencia a la tracción por escopleo y el aumento de la absorción.

Palabras clave: Residuos Plásticos; Resistencia; ANOVA; Microestructura.

INTRODUCTION

Present-day environmental threats include global warming and environmental deterioration. Massive increases in the creation of solid waste paralleled the development in population capacity. These wastes can either degrade over time or not.(1) Sustainability is employed as the rationale and guiding principle for the progression of industry and production. The topic of sustainable construction has garnered significant media attention in recent years. There are multiple strategies to mitigate environmental damage. In order to minimize the presence of solid wastes in the environment for as long as possible, one option is to integrate them into other enduring ventures. The utmost essential the concrete industry is considered one of these sectors because of its long-lasting durability. Indeed, these elements have the potential to render it more bearable and reduce the consumption of primary materials like sand, gravel, and cement. Recently, research has been undertaken to get further knowledge. Whether or not this waste can be incorporated into concrete without taking into account the strength of the concrete as a crucial criterion.(2) Recycling plastics provided a permanent remedy for the waste issue by being used as gravel, sand, or fibers in concrete.(3,4) When used as an alternate aggregate against attacks from sulfuric acid. Additionally, the majority of concrete structures fail because of aggregate crushing. Compared to stone aggregates, Plastic aggregates that crush poorly are heavier and more challenging to break up. Since it was impossible to replace natural aggregate, using varying percentages of plastic aggregate as a partial substitute was tested.(4) The characteristics of cement mortar made from polyethylene waste that has been treated with a reactive substance are examined and contrasted with those of ordinary cement mortar and polyethylene waste. The recent findings show that the properties of polyethylene cement mortar are considerably improved by curing the polyethylene with cement. Furthermore, the outcomes demonstrate that all treatments enhanced the cement mortar’s qualities as compared to polyethylene that had not been treated.(5) However, compared with a mix without plastic,(6) it reduced compressive strength and bond while increasing tensile strength.(6) Jain et al.(7) employed the trash from plastic bags in concrete to address the issue of rising waste and to create high-quality, inexpensive concrete that is advantageous to both building construction and plastic recycling. The effects on the characteristics of concrete were examined with the use of 5 %, 10 %, 15 %, and 20 % crushed WPB in place of natural fine aggregate. Its specific gravity is 0,39, and the results showed that with increasing waste content, water absorption increased while concrete properties like slump, unit weight, compressive, flexural strengths, and elastic modulus dropped. Hama (8) examined the viability of replacing coarse aggregates in part with local garbage, such as the caps from plastic water bottle bottles. Different plastic aggregate ratios utilized in plastic samples (15 %, 30 %, 40 %, 50 %, 60 %, and 75 %) were examined. The outcomes revealed that the ultimate bond strengths, cracking tensile strength, compressive strength, and flexural strength enhanced with the 15 % and 30 % plastic ratios, especially at 15 %. Contrarily, these advantages began to decrease as the plastic concentration surpassed 30 %. Moreover, with the plastic present, structural characteristics improved, especially at lower rates. The findings show that When used as a gravel component in reinforced concrete for construction, (15 and 30)% plastic can be used successfully.

Most research has dealt with the effect of plastic, especially polyethylene-type (PET), on the properties of concrete. However, there are numerous plastic waste generators whose effects on concrete can be investigated and utilized. In this work, polyethylene waste resulting from the production of the plastic part in cooking gas valve bottles from local factories was used. Five mixtures were produced using partial sand replacement at five percentages (5 %, 7,5 %, 10 %, 12,5 %, 15 %) of crushed plastic waste by volume, in addition to the control mixture for comparison purposes. The effect of this type of plastic on the soft, mechanical, bonding, impact, absorption, and microstructural properties of concrete was studied.

Experimental program

Materials

Cement: ordinary Portland cement (OPC) Type CEM I, from AL-MASS Company in Iraq, with 3,15 specific gravity, was used as a binder to cast all mixes. According to Iraqi standard No. 5,(9) the cement was used.

Aggregate: as a fine aggregate, natural fine sand, which is a material with a specific gravity of 2,62 and a larger particle size of 4,75 mm, was used. Table 1 shows the analysis of sieves for sand.

Crushed gravel: with a maximum size of 10 mm, was used as a coarse aggregate. Having a specific gravity of 2,68.(10) Table 2 lists the analysis of sieves for Gravel.

|

Table 1. Analyses of sieves for sand |

||

|

Sieve size(mm) |

Cumulative passing % |

IQS limits, zone 2 |

|

10 |

100 |

100 |

|

4,75 |

97,1 |

90-100 |

|

2,36 |

82,2 |

75-100 |

|

1,18 |

66,4 |

55-90 |

|

0,6 |

49,4 |

35-59 |

|

0,3 |

16,2 |

8-30 |

|

0,15 |

2,1 |

0-10 |

|

Table 2. Analyses of sieves for gravle |

||

|

Sieve size(mm) |

Cumulative passing % |

IQS limits, |

|

14 |

100 |

100 |

|

10 |

94,5 |

85-100 |

|

4,75 |

0,5 |

0-25 |

|

2,36 |

0,2 |

0-5 |

Plastic: waste polyethylene from the production of the plastic part in the cooking gas valve bottles was used in the current investigation’s plastic. The waste was collected from local factories, crushed into fine aggregate with 1,56 specific gravity, and used in this investigation. Table 3 lists the particle size of waste Plastic.

|

Table 3. Particle size of waste plastic |

|

|

Sieve size(mm) |

Cumulative passing % |

|

10 |

100 |

|

4,75 |

99,2 |

|

2,36 |

16,6 |

|

1,18 |

3,8 |

|

0,6 |

1,6 |

|

0,3 |

0,6 |

|

0,15 |

0,3 |

Figure 1. Used Materials

Superplasticizer: this study used SikaViscoCrete-180GS (F and G) polycarboxylate solution, which conforms to ASTM C 494-13,(11) as a superplasticizer to improve concrete workability and is used as a percentage of cement weight.

Mix Proportion

All concrete samples were poured in a mixture (1:1,75:2,5) with a water/cement ratio of 0,34 and a superplasticizer content of 0,0125 by weight of cement. The mixing ratios from earlier research were utilized, experiments were performed, and the desired mixing ratios were achieved. Six mixes were created using various ratios to partially replace the sand content (0 %, 5 %,7,5 %,10 %,12,5 %, and 15 %) of crushed waste plastic by volume. Table 4 shows mix proportions per cubic meter (kg/m3). Concrete was then cast into molds, after which it was kept in the lab for 24 hours. Samples were maintained in a water basin after being taken out of the molds for (7 and 28) days before being tested.

|

Table 4. Particle size of waste plastic |

||||||

|

|

0 %P |

5 %P |

7,5 %P |

10 %P |

12,5 %P |

15 %P |

|

Cement |

400 |

400 |

400 |

400 |

400 |

400 |

|

Fine Agg. |

700 |

665 |

647,5 |

630 |

512,5 |

595 |

|

Waste plastic |

0 |

8,6 |

12,86 |

17,1 |

21,4 |

25,7 |

|

Coarse Agg |

1000 |

1000 |

1000 |

1000 |

1000 |

1000 |

|

Water |

136 |

136 |

136 |

136 |

136 |

136 |

|

Superplasticizer |

5 |

5 |

5 |

5 |

5 |

5 |

Testing Program

Slump Test: In fresh conditions, one of the most crucial characteristics of the concrete mix is slump. It suggests the usability of recently placed concrete. The test was conducted according to ASTM C143-12.(12)

Dry Density Test: According to ASTM C642-13,(13) the hardened density was measured using cubes (100×100×100 mm), as illustrated in figure 4.

Absorption Test: According to ASTM C642-13,(13) cube samples with dimensions of 100 mm were weighed wet after being taken out of the water bath. They were dried for around 24 hours in an electric oven at 100° C, as indicated in figure 5, before being weighed again. Equation 1 was used to compute the absorption.

Absorption % = (B-A)/A × 100 ….(1)

Where: A = Dried sample weight. B = Fully saturated weight.

Compressive Strength Test: According to ASTM C39/C39M,(14) The compressive strength (f ‘c) of concrete mixtures after 28 days of curing was measured using cylinder specimens with diameters of (150*300 mm).

Flexural Strength Test: Based on ASTM C78/C78M, a hydraulic machine was used to test the flexural strength of prismatic samples with (100*100*500) diameters.(16)

Splitting Tensile Test: The same apparatus used for compressive strength testing was used to conduct a splitting tensile strength test on cylinder samples (100 mm * 200 mm)after 28 days from curing. As required by ASTM, this test was conducted C496/C496M.(17)

Ultrasonic Velocity Test: The Samples with dimensions(100×100×100 mm) were evaluated using ultrasonic equipment to establish the ultrasonic pulse’s velocity based on ASTM C597-09.(18) The velocity can be calculated using this time and equation (2).

V=L/T … (2)

Where: V= Pulse velocity(m/s), L=length(m). T = time(s).

Impact Test: A concrete disk with a diameter of 150 mm and a height of 63,5 mm was used for the impact test; this was carried out based on ACI 544,2R.(19) An iron ball weighing 1182 g was repeatedly struck with a 4,536 kilogram (kg) hammer dropped from a height of 0,4572 m. Each concrete sample underwent the test until it failed. Using equation (3), the number of blows was counted, and the energy absorbed was estimated.

EI = Nmgh (3)

Pull-out Test: As depicted in figure 8 and in accordance, cubic samples measuring (100 *100 *100 mm) and a steel bar measuring around 10 mm were used with RILEM-TC RC 6.(20) The rebar was 550 mm lengthy, with 50 mm on the outside and 100 mm cast inside of the concrete cube.

Figure 2. Experimental tests

RESULT AND DISCUSSION

Slump

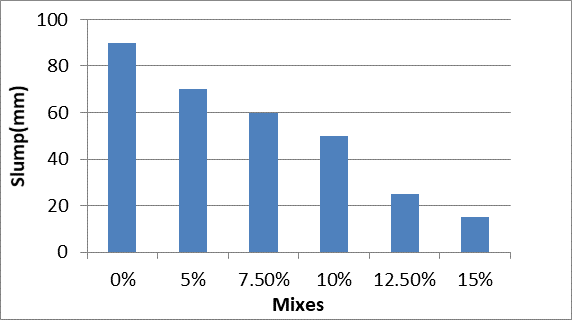

The results of the slump value were reduced when plastic aggregate (P) was added to the concrete mixture by, successively, 22,2 %, 33,3 %, 44,4 %, 72,2 %, and 83,3 percent for (5 %, 7,5 %, 10 %, 12,5 %, and 15 %), as compared to the reference mixture (0 %) plastic. (figure 3) Plastic waste particles’ jagged edges increased friction between particles and reduced workability, so there was less of a slump when sand was substituted with plastic aggregate. Other academics who utilized various types of discarded plastic also discovered a decrease in slump.(21)

Figure 3. Slump for all mixes

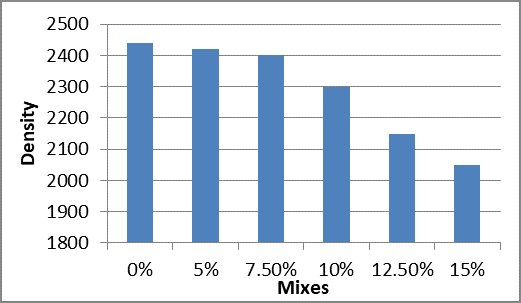

Dry Density Test

The laboratory analysis revealed, as shown in figure 4, that the density went downward when waste plastic (W.P) was added. For mixes containing (5 %, 7,5 %, 10 %, 12,5 %, and 15 %) waste plastic, respectively, it was lowered by (0,82 %, 1,6 %, 5,7 %, 11,9 %, and 16 %) from the reference mix’s 2440 kg/m3. The reason for this pattern is that W.P. has a lesser density than sand made naturally, which influences the decline in concrete’s density. Many academics, such as Patil et al. and Kuhair et al.(22,23), came to a similar conclusion. Regardless of the type and size of replacement, using plastic as an aggregate typically reduces unit weight.

Figure 4. Dry Density for all mixes

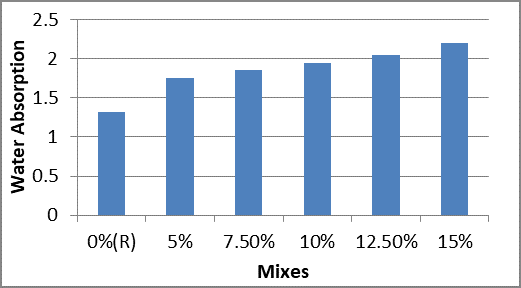

Absorption Test

The test results for water absorption see figure 5 showed that the absorption increased by (32,6 %, 41 %, 47,7 %, 55,3 %, and 66,7 %), respectively, when the plastic ratio was raised by (5 %, 7,5 %, 10 %, 12,5 %, and 15 %). The higher porosity ratio brought on by plastic trash causes an increase in the water absorption of concrete using plastic aggregate.(7)

Figure 5. Absorption for all mixes

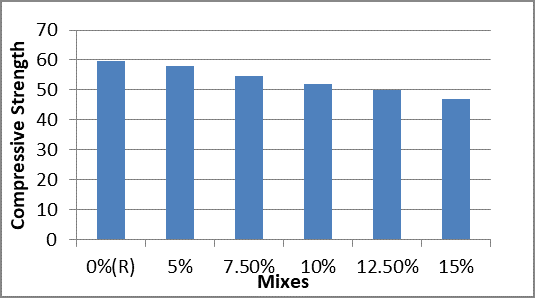

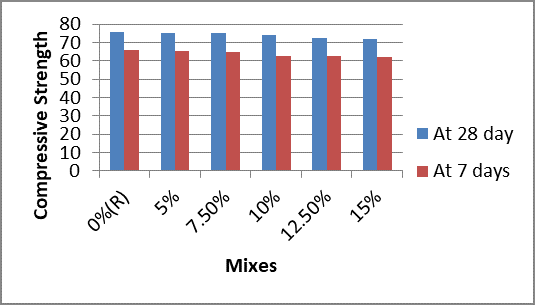

Compressive Strength Test

Two types of models were examined: concrete cubes aged 7 and 28 days and concrete cylinders aged 28 days. Figure 7 clarifies the cubic compressive strength with and without crushed waste plastic at 7 and 28 curing ages. After seven days, the average compressive strength of cubes decreased by about (0,3 %, 1,1 %, 4,4 %, 5 %, and 5,5 %) for specimens with (5 %, 7,5 %, 10 %, 12,5 %, and 15 %), respectively. The compressive strength decreased as the proportion of plastic aggregate increased; this could be because plastic aggregate behaves like concentration areas for stresses, which causes damage to spread more quickly. Plastic aggregate also has less resistance and more rigidity than natural aggregate. Additionally, pores started to form in the concrete mix because the plastic particles were bigger than sand.(8) At 28 days, the average compressive strength for cylinders decreased by about( 0,8 %, 0,8 %, 2 %, 4,5 % and 5 %) for specimens with (5 %, 7,5 %, 10 %, 12,5 %, and 15 %), respectively.

Figure 6. Compressive Strength for of Cylinders

Figure 7. Compressive Strength for of Cubes

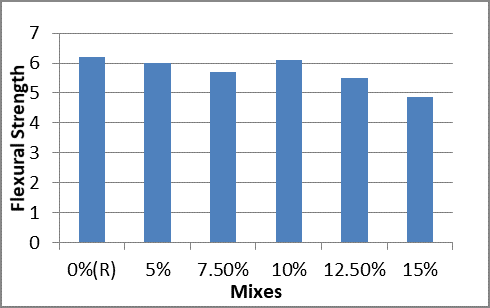

Flexural Strength Test

Figure 8 displays the flexural strength results. Flexural strength decreased by (3,2 %, 8,1 %, 1,6 %, 11,3 %, and 21,8 %) when adding (5 %, 7,5 %, 10 %, 12,5 %, and 15 %) waste plastic, respectively; a result of the paste matrix’s and plastic aggregate’s frail connections, adding plastic aggregate to the concrete matrix decreased its splitting and bending strengths, several specimens were unsuccessful due to deboning from the cement mixture.(24)

Figure 8. Flexural strength for all mixes

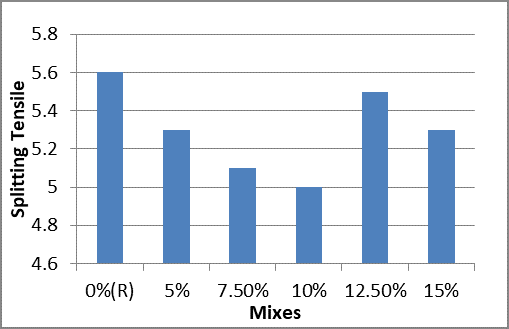

Splitting Tensile Strength Test

Figure 9 displays the splitting tensile strength decreases by (5,4 %, 9 %, 10,7 %, 1,8 %, and 5,4 %) for mixes with (5 %, 7,5 %, 10 %, 12,5 %, and 15 %) waste plastic, respectively.

Figure 9. Splitting strength for all mixes

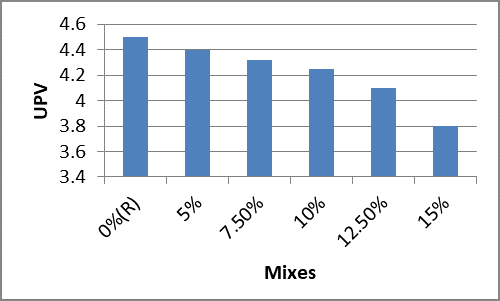

Ultrasonic Velocity Test

Figure 10 depicts a declining trend relative to the reference mix of roughly 2,2 %, 4 %, 5,6 %, 8,9 %, and 15,6 % for mixes containing (5 %, 7,5 %, 10 %, 12,5 %, and 15 %), respectively. The pulse partially diffused when it went through various materials, which caused the UPV to decrease in concrete that contained plastic aggregate. Additionally, waves were obstructed, and their velocity decreased in some areas using plastic aggregate instead of natural sand.(25,26)

Figure 10. UPV for all mixes

Impact Test

The results are shown in figure 11. (5 %, 7,5 %, 10 %, 12,5 %, and 15 %), the rise was (131,9 %, 142,8 %, 160,7 %, 185,7 %, and 203,6 %), correspondingly, compared to 0P. Plastic aggregate is more flexible and has higher elastic qualities than natural aggregate; it was found that as the amount of plastic aggregate in concrete grew, so did its energy absorption. This enhanced the flexibility of concrete and, as a result, increased the ability of specimens to absorb energy. Other researchers who used different kinds of plastic reached the same conclusions, but their findings all pointed to concrete’s improved impact resistance when plastic was added.(27,28)

Figure 11. Impact energy for all mixes

Pull out Test

Figure 12 shows that plastic injection weakens the link between concrete and steel reinforcement. For (5 %, 7,5 %, 10 %, 12,5 %, and 15 %), the changes were (3,5 %, 6,1 %, 8,4 %, 12,8 %, and 18,6 %, respectively). The absence of a chemical reaction between the plastic aggregate and the cement paste and the smooth surface of the plastic used in this study are the leading causes of the reduction in bond strength caused by the incorporation of plastic.(29,30) As a result, the cement matrix and the steel bar have a weak bond.

Figure 12. Ultimate bond strength for all mixes

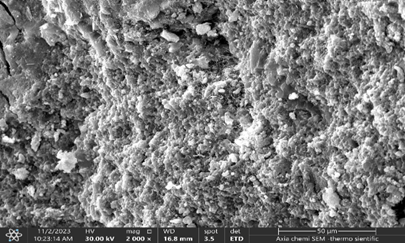

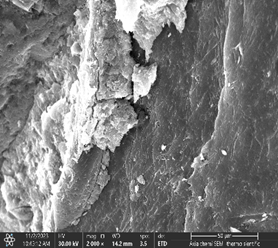

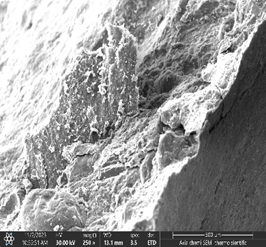

Influence of Waste Plastic as Fine Aggregate on Concrete Microstructure

The cement matrix’s bond and crack width with both conventional and plastic aggregates are depicted in figures 13. The weak point between the cement matrix and plastic aggregate seen in these SEM pictures could be the cause of the concrete mixes with plastic aggregates losing strength more quickly than those with natural aggregates. This outcome also suggests that the plastic-containing concrete was porous, which may be another factor contributing to its decreased strength. The compounds that make up plastic garbage are very different from the natural aggregate’s structure; for example, plastic is weakly neutral. These features lead to the loss of mechanical qualities by determining a limited interface adhesion between the replacement and the cement.(31)

|

|

|

|

Reference sample |

|

|

|

|

|

Concrete contains plastic aggregate |

|

Figure 13. SEM image of plastic waste concrete

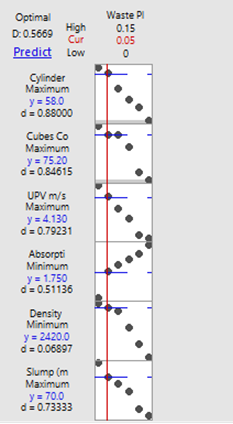

Statically analysis

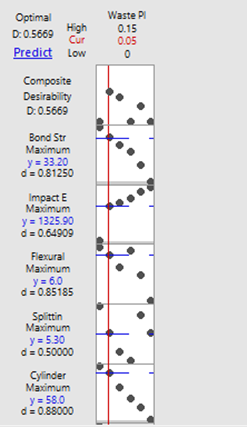

ANOVA analysis was conducted using Minitab to establish the optimal quantity of waste plastic (P) to incorporate into concrete. An analysis of variance was used to establish whether or not an independent variable impacted the dependent variable. Properties have been chosen as dependent elements, while P content has been selected as an independent element after considering all of the qualities above. According to the analysis process, 5 % of (P) was the recommended amount, as shown in figure 14.

Figure13. Optimization Analysis

CONCLUSION

1. Due to the irregular shape and sharp edges of the plastic particles, the slump of fresh concrete mixes decreased as the proportion of plastic increased, which increased friction between the inner particles and decreased the workability of the concrete.

2. The addition of waste plastic reduced the density of the concrete. This results from waste plastic’s lower unit weight than natural sand.

3. The absorption test demonstrated that, due to the increased porosity ratio of waste plastic, the absorption rose as the waste plastic content increased by the previously indicated ratios.

4. The addition of waste plastic to the reference mixture resulted in a decrease in compressive, flexural, and splitting strengths.

5. Due to the pulse’s transmission through different materials, the pulse velocity rate was reduced when plastic was added.

6. Due to the elastic characteristics and flexibility of plastic compared to natural aggregate, it has been observed that concrete’s energy absorption increases as plastic aggregate content increases. Using plastic, the bond between concrete and steel reinforcement weakened.

7. The weak point between the cement matrix and plastic aggregate seen in these SEM pictures could be the cause of the concrete mixes with plastic aggregates losing strength more quickly than those with natural aggregates.

8. The findings of this test showed that the optimal ratio was 5 % plastic as a fine aggregate because it slightly decreased strength compared to the other mixes.

REFERENCES

1. Yeheyis M, Hewage K, Alam MS, Eskicioglu C, Sadiq R. An overview of construction and demolition waste management in Canada: a lifecycle analysis approach to sustainability. Clean Technologies and Environmental Policy. 2013; 15(1):81-91.

2. Moussa Thiam, Mamadou Fall, M.S. Diarra. Mechanical properties of a mortar with melted plastic waste as the only binder: Influence of material composition and curing regime, and application in Bamako. Case Studies in Construction Materials. Volume 15, December 2021, e00634. https://doi.org/10.1016/j.cscm.2021.e00634

3. Aziz K. I., Hama S. M., Kuhair H. M. (2018). Efficiency of Waste Plastic Fiber on Behavior of Composite Steel Plate- Concrete Push Out Test “ 11th International Conference on Developments in eSystems Engineering (DeSE). 335-339. DOI 10.1109/DeSE.2018.00066

4. T K Mohammed, S M Hama. Effect of combination of waste glass powder and plastic aggregate on structural behavior of reinforced concrete beams. Structures 52 (2023) 83–103. https://doi.org/10.1016/j.istruc.2023.03.160

5. Nahla N. Hilal1, Mohammed T. Nawar, and Abdulkader I. Al-Hadithi. Effect of Treated Polyethylene Waste on Some Mechanical Properties of Cement Mortar. Key Engineering Materials: 2020, Vol. 870, pp 3-9

6. D. N. Hamdullah, S. M. Hama and S. M. Hama, “Optimum Content of Waste Fine Plastic Aggregate Using Mini181 Software for Best Performance of Reinforced Concrete,” 2021 14th International Conference on Developments in eSystems Engineering (DeSE), Sharjah, United Arab Emirates, 2021, pp. 318-322, doi: 10.1109/DeSE54285.2021.9719433.

7. Jain A, Siddique S, Gupta T, Sharma RK, Chaudhary S. Utilization of shredded waste plastic bags to improve impact and abrasion resistance of concrete. Environ Dev Sustain [Internet]. 2020;22(1):337–362. Available from: https://doi.org/10.1007/s10668-018-0204-1.

8. Hama SM. Evaluations of strengths, impact and energy capacity of two-way concrete slabs incorporating waste plastic. J King Saud Univ - Eng Sci [Internet]. 2021;33(5):337–45. Available from: https://doi.org/10.1016/j.jksues.2021.09.007.

9. Iraqi Specifications, No. 5 1984. Iraq Seismic Code for Concrete 304. Portland Cement. Central Agency for Standardization and Quality Control, Planning Council, Baghdad, Iraq. 1984.

10. Iraqi Specification No. 45, 1984. Aggregate from natural sources for concrete and construction. Baghdad, Iraq. 1984.

11. ASTM C494/C494M-13. Standard Specification for Chemical Admixtures for Concrete. Annu B ASTM Stand. 2013.

12. ASTM C143/C143M-12. Standard Test Method for Slump of Hydraulic Cement Concrete. 2012; vol. 04.02:1–4.

13. ASTM C642-13. Standard test method for density, absorption, and voids in hardened concrete. American Society for Testing and Materials. 2013.

14. ASTM C39 / C39M-05, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens, ASTM International, West Conshohocken, PA, 2005, www. astm. org. https://doi.org/10.1520/C0039_C0039M-05.

15. BS 12390-3. Testing Hardened Concrete: Compressive Strength of Test Specimens. British Standard Institution, London. 2009.

16. ASTM C78 / C78M-21, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading), ASTM International, West Conshohocken, PA, 2021, www. astm. org. https:// doi. org/ 10. 1520/ C0078_ C0078M- 21.

17. ASTM C496 / C496M-17, Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens, ASTM International, West Conshohocken, PA, 2017, www. astm. org. https:// doi. org/ 10. 1520/ C0496_ C0496M- 17.

18. ASTM C597-09. Standard test method for pulse velocity through concrete. American Society for Testing and Material. 2009.

19. ACI PRC-544.4–18: Guide to Design with Fiber-Reinforced Concrete. ACI, West Conshohocken, PA, 2018.

20. RILEM (Ed.) RILEM-TC RC 6 Bond test for reinforcement steel.2. Pull-out test, 1983. In RILEM Recommendations for the Testing and Use of Constructions Materials; E & FN SPON: New York, NY, USA, 1994; pp. 218–220. ISBN 2351580117.

21. Hama SM, Hilal NN. Fresh properties of concrete containing plastic aggregate. In F. Pachego-Torgal, J. Khatib, F. Colangelo, and R. Tuladhar (Eds.). Use of recycled plastics in eco-efficient concrete. 2019; (Chapter 5, pp. 85–114). Elsevier. ISBN 9780081026762. https:// doi. org/ 10. 1016/ B978-0- 08- 102676- 2. 00005-0

22. Patil PS, Mali JR, Tapkire GV, Kumavat HR. Innovative techniques of waste plastic used in concrete mixture. Int J Res Eng Technol. 2014;3(09):29–32.

23. Kuhair H, Hama S, Aziz K. Long–term behavior of composite steel plate-concrete slabs incorporating waste plastic fibers. Mag Civ Eng. 2022; 109(1):10904. https://doi.org/10.34910/MCE.109.4

24. Mohammed TK, Hama SM. Mechanical properties, impact resistance and bond strength of green concrete incorporating waste glass powder and waste fine plastic aggregate. Innov Infrastruct Solut 2022;7:49. https://doi.org/10.1007/s41062- 021-00652-4

25. Nahla Hilal, Taher A. Tawfik, Hadi Hemdan Edan & Nadhim Hamah Sor (2022): The mechanical and durability behaviour of sustainable self-compacting concrete partially contained waste plastic as fine aggregate, Australian Journal of Civil Engineering, DOI: 10.1080/14488353.2022.2083408

26. Almeshal I, Tayeh BA, Alyousef R, Alabduljabbar H, Mohamed AM. Eco-friendly concrete containing recycled plastic as partial replacement for sand. J Mater Res Technol. 2020;9(3):4631–4643.

27. Suwaid H, Aziz K, Hama S. Behavior of composite steel plate-sustainable concrete slabs under impact loading. Mag Civ Eng. 2021;106(6):10604. https://doi.org/10.34910/MCE.106.4

28. Mohammadhosseini H, Abdul Awal ASM, Mohd JB, Yatim. The impact resistance and mechanical properties of concrete reinforced with waste polypropylene carpet fibres. Construct Build Mater 143:147–157. https:// doi. org/ 10. 1016/j. conbu ildmat. 2017; 03: 109

29. Bhogayata AC, Arora NK (2018) Impact strength, permeability and chemical resistance of concrete reinforced with metalized plastic waste fibers. Constr Build Mater 161:254–266. https://doi.org/10.1016/j.conbuildmat.2017.11.135

30. Sheelan Mahmoud Hama, Hend S. Zayan, Shaho Mahmoud Hama. The behavior of concrete incorporating ring shape waste plastic fibers under different load conditions. Innovative Infrastructure Solutions (2023) 8:134. https://doi.org/10.1007/s41062-023-01105-w

31. Alessandra Merlo, Luca Lavagna, Daniel Suarez-Riera , Matteo Pavese. Mechanical properties of mortar containing waste plastic (PVC) as aggregate partial replacement. Case Studies in Construction Materials. Volume 13, December 2020, e00467. https://doi.org/10.1016/j.cscm.2020.e00467.

FINANCING

None.

CONFLICT OF INTEREST

None.

AUTHORSHIP CONTRIBUTION

Conceptualization: R Abeer Muayad Saleh, Sheelan Mahmoud Hama.

Research: Abeer Muayad Saleh, Sheelan Mahmoud Hama.

Writing - original draft: Abeer Muayad Saleh, Sheelan Mahmoud Hama.

Writing - revision and editing: Abeer Muayad Saleh, Sheelan Mahmoud Hama.