Categoría: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

The Influence of Calcined Alumina Additives on the Mechanical Properties and Chloride-Induced Corrosion of Blended Concrete

Influencia de los aditivos de alúmina calcinada en las propiedades mecánicas y la corrosión inducida por cloruros del hormigón mezclado

Nora AL-Anssari1,2 *, Abbas AL-Ameeri1 *

1Civil Engineering Department, College of Engineering, University of Babylon. Babylon, Iraq.

2Building and Construction Techniques Engineering Department, AL-Mustaqbal University. Babylon, Iraq.

Cite as: AL-Anssari N, AL-Ameeri A. The Influence of Calcined Alumina Additives on the Mechanical Properties and Chloride-Induced Corrosion of Blended Concrete. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:814. https://doi.org/10.56294/sctconf2024814

Submitted: 19-01-2024 Revised: 01-04-2024 Accepted: 27-05-2024 Published: 28-05-2024

Editor: Dr.

William Castillo-González ![]()

Note: paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

The development and use of blended concrete systems have been growing rapidly in the construction industry, mainly due to cost savings, energy savings, and sustainability. This paper represents the influence of Calcined Alumina (AC) on the strength and chloride-induced corrosion of concrete. AC, at various contents, was appropriately added as a partial replacement for ordinary Portland cement (OPC) in blended mixtures (3,5 and 7 % by mass of OPC). To find out its impact on the fresh properties (slump flow), hardened properties (compressive and splitting strength), and durability properties (water absorption at, rapid chloride migration coefficient, chloride penetration resistance, and corrosion resistance) depending on curing ages. Moreover, it investigates the effect of crack width on chloride penetration and corrosion rate. The results reveal that the addition of AC has a positive impact on concrete. Whereas obtained a decrease in the workability of concrete and an increase in the water demand. On the other hand, a significant increase in the compressive strength, tensile strength, and durability properties of concrete was recorded. Also, the replacement of cement with 7 % AC achieved the highest value of compressive strength (63,67 MPa) in 90 days. Also, improvements in chloride penetration resistance and corrosion rate. The presence of Al₂O₃ reduces the ingress of chloride ions into concrete considerably, leading to the conclusion that the decrease in crack width is due to a decrease in corrosion steel products and the chloride penetration concentration and depth.

Keywords: Blended Concrete; Calcined Alumina; Chloride-Induced Corrosion; Fresh Properties; Mechanical Properties; Durability of Concrete.

RESUMEN

El desarrollo y uso de sistemas de hormigón mixto ha crecido rápidamente en la industria de la construcción, principalmente debido al ahorro de costes, ahorro de energía y sostenibilidad. Este trabajo representa la influencia de la alúmina calcinada (AC) sobre la resistencia y la corrosión inducida por cloruros del hormigón. La alúmina calcinada, en diferentes proporciones, se añadió como sustituto parcial del cemento Portland ordinario (OPC) en mezclas mixtas (3,5 y 7 % en masa de OPC). Para averiguar su impacto en las propiedades en fresco (flujo de asentamiento), propiedades endurecidas (resistencia a la compresión y a la rotura), y propiedades de durabilidad (absorción de agua a, coeficiente de migración rápida de cloruros, resistencia a la penetración de cloruros, y resistencia a la corrosión) en función de las edades de curado. Además, se investiga el efecto de la anchura de la grieta sobre la penetración del cloruro y la velocidad de corrosión. Los resultados revelan que la adición de CA tiene un impacto positivo en el hormigón. Mientras que se obtuvo una disminución de la trabajabilidad del hormigón y un aumento de la demanda de agua. Por otra parte, se registró un aumento significativo de la resistencia a la compresión, la resistencia a la tracción y las propiedades de durabilidad del hormigón. Asimismo, la sustitución del cemento por un 7 % de CA alcanzó el valor más alto de resistencia a la compresión (63,67 MPa) en 90 días. También se observaron mejoras en la resistencia a la penetración de cloruros y en la velocidad de corrosión. La presencia de Al₂O₃ reduce considerablemente la entrada de iones cloruro en el hormigón, lo que permite concluir que la disminución de la anchura de las fisuras se debe a una disminución de los productos de acero de corrosión y de la concentración y profundidad de penetración del cloruro.

Palabras clave: Hormigón Mezclado; Alúmina Calcinada; Corrosión Inducida por Cloruros; Propiedades Frescas; Propiedades Mecánicas; Durabilidad del Hormigón.

INTRODUCTION

Nowadays, additives based on CaO and Al₂O₃ have become common due to their highly effective reaction with cement hydration products,(1) leading to improvement in both the strength and durability of concrete. Calcined Alumina (AC) is a micro white additive whose main component is alumina (≥99 %). The powder characteristics and components of calcined alumina powders differ based on the producer and the manufacturing process that is used. This product is used appropriately as a partial replacement of ordinary Portland cement, to reduce the cement.(2) Micro Al₂O₃ are effectively used due to their particle size and pozzolanic reaction with calcium hydroxide Ca (OH)₂ which is the main component produced in the hydration of cement which also leads to the formation of calcium silicate-hydrate (C-S-H) gels.(3) The rate of the pozzolanic reaction is proportional to the available surface quantity for the reaction.(4) Another beneficial effect of the presence of Al₂O₃ in large concentrations that could react with the CaCO₃ present in the concrete to produce hemi-carbo-aluminate and mono-carbo-aluminate which can act as a filler.(5) thereby, The addition of Al₂O₃ can densify the concrete microstructure and can significantly improve the volumetric stability of concrete.(6) This results in significant improvement of mechanical properties and durability of the concrete with different ages.(2,7,8,9) As known when fineness increases, surface area increases due to an increase in the surface area and the filling ability between particles of aggregates and micro particles thus the workability, and strength of concrete improves.(10) It was reported that the incorporation of Al₂O₃ could accelerate the formation of hydrated products, and enhance the pores structure leading to a decrease in the workability of fresh concrete, and water absorption as well.(11) Furthermore, AC has less water and chloride penetration into concrete which is due to the accelerated hydration process. Meanwhile, by adding just a small content of this material, the durability and strength of concrete are improved.(12) However, it is worth noting that there are limited studies that have focused on using micro alumina additives in concrete. Shokravi et al.(12) took alumina additive as an essential element to exploring the mechanical characteristics of concrete. AC makes the concrete matrix more compact and homogeneous, that could provide more substantial compressive strength compared to the concrete without Al₂O₃.(13) This research focuses on the influence of calcined alumina (AC) on the parameters of blended concrete system, which has been different from the previous research, by attempted a method to mitigate chloride ion ingress in concrete by using AC as an additive and provided a discussion on the results of fresh properties, hardened properties, and other durability properties, as well as suggestions for future studies.

Experimental Work

Materials

In this study, Alumina calcined was used and appropriately replaced with OPC-CEMI cement (42,5R) by an amount of 3,5 % and 7 % in a binary cementitious mixture, OPC cement satisfied with the Iraqi Standard Specification IQS(NO.5/2019).(14) While AC was provided by the manufacturer (Kaifeng Datong Refractory). The compound compositions of used materials are given in table 1.

|

Table 1. The main compounds composition of OPC and AC |

||

|

Compound composition |

OPC% |

AC% |

|

Lime (CaO) |

61,52 |

- |

|

Alumina (Al2O3) |

5,33 |

≥99 |

|

Silicate (SiO2) |

21,67 |

≤ 0,2 |

|

Iron oxide (Fe2O3) |

3,31 |

≤ 0,2 |

|

Sulphate content% |

2,45 |

0 |

Natural sand with an apparent specific gravity of 2,6, fineness modulus of 2,41, and absorption of 2,6 % was used. Crushed aggregate with an apparent specific gravity of 2,64, absorption of 0,75 %, and maximum size (19,5 mm) was also used. Both were conforming to the Iraqi standard specifications (IQS No.45/1984).(15) Also, during this study, a range of water-reducing and super plasticizing admixtures for concrete was utilized and is called Sika’s ViscoCrete 180G which achieves the requirements of (ASTM C-494)/2015 Type F(16) which is considered to be used with Portland cement at amount of 1 % by mass of cement, see figure 1.

Figure 1.

Materials used in this study

Mixture proportions and Mixing Procedure

An overall of three mixtures were designed according to (ACI 211_1_91) method(17) and cast in the laboratory at the water-to-binder ratio (w/b) of 0,45. The mixing water was used for all the mixtures, the mixtures are organized using ordinary Portland cement OPC and alumina calcined as a partial replacement of cement. The mix proportions are presented in table 2, see figure 2.

|

Table 2. The mixing proportions of concrete |

||||||

|

Mix |

Mass per one meter cube of concrete (kg/m³) |

|||||

|

Cement |

AC |

Water |

Sand |

Gravel |

SP |

|

|

PC |

420 |

0 |

189 |

624 |

1140 |

4,2 |

|

AC 3,5 % |

405 |

14,7 |

189 |

624 |

1140 |

4,2 |

|

AC 7 % |

390,6 |

29,4 |

189 |

624 |

1140 |

4,2 |

Figure 2. Casting of specimens

Curing and Testing

The concrete mixes in this study were cast as specimens and then tested according to the standard specifications as follows:

Slump test of freshly mixed concrete was measured according to BS EN 12350-2:2019.(18) The slump flow apparatus presented in figure 3.

.

.

Figure 3. Slump flow test

To obtain the compressive strength and water absorption, cubic specimens (100×100×100) mm was used according to BS EN 12390-3:2019(19) and BS EN 12390-7: 2009(20) respectively, as shown in figure 4 and 5.

Figure 4. Compressive strength test

Figure 5. Water absorption test

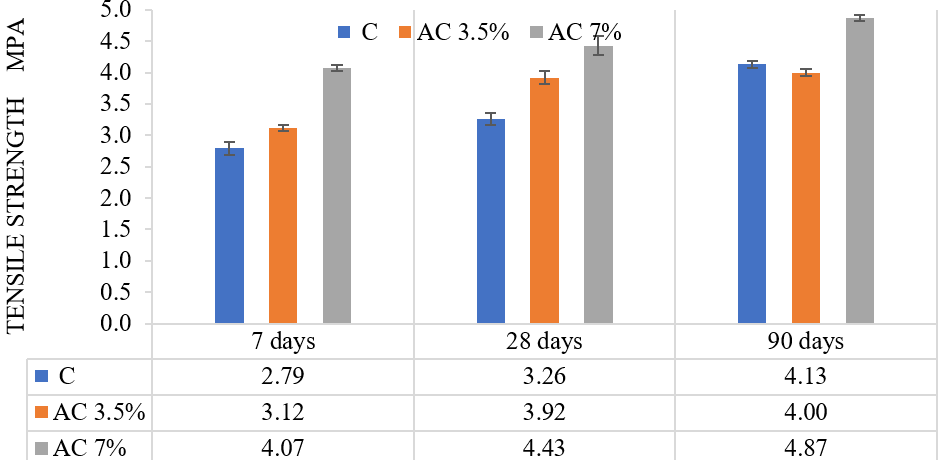

(200×100) mm, cylinders were used to obtain the splitting tensile strength test according to BS EN 12390-6:2009(21) as shown in figure 6.

Figure 6. Tensile strength test

(100×50) mm, a slice of a cylinder to determine rapid chloride migration test RCMT according to NT-Build 492:1992.(22) The test method presented in figure 7.

Figure 7. Rapid chloride migration test

(200×100×100) mm prisms was used to determine natural chloride penetration test(23) and impressed current test.(24,25) See figure 8 and 9.

Figure 8. Chloride penetration test

Figure 9. Impress current test

The specimens were covered with plastic sheets for the first 24 hours, then the specimens were taken from the molds and stored in curing water tanks at 25°C until the tests ages.

RESULTS AND DISCUSSION

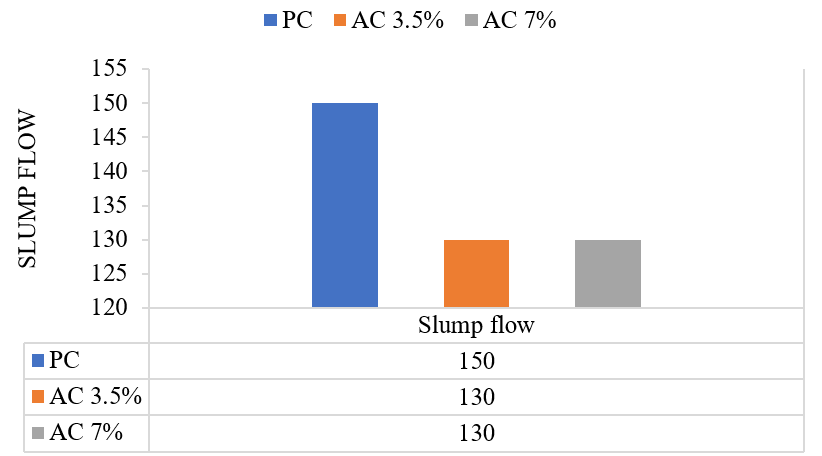

Results of Fresh Properties

The workability of freshly mixed concrete was measured using the slump-flow test. As it can be seen from figure 10, the slump values of concrete without AC were higher than the slump values of concrete containing AC. The control concrete mixture made with OPC showed that the value of slump (150 mm), while AC had a slight effect on the slump, decreased up to 130 mm for both mixtures made with 3,5 % and 7 % AC. This can be attributed to the high specific surface of them, which absorbs water and contributes to increased water demand to maintain mixing and control the concrete’s workability.(5) M. Seifan et al.(26) observed that workability of all dosages of Al₂O₃ samples was just slightly a lesser than workability of the samples without Al₂O₃ due to high ratio of surface area to volume. M. Khopade et al.(27) reported that the mixes that contained Al₂O₃ had a lower slump than the controlled specimens owing to the softness of the Al₂O₃, which enhanced the properties of the concrete like filling, bonding, and evenness and also reduced the diffusion diameter of the concrete in slump flow. Similar findings were reported.

Figure 10. Reduction of slump flow due to replacement of OPC by AC

Results of Hardened Properties

In the experiment, the compressive and splitting tensile strengths were measured at the ages of 7, 28, and 90 days. The results of compressive and splitting tensile strength improvement are shown in figures 11 and 12, respectively. As it can be seen, all concrete mixtures gained an increase in strength values over the curing period. With an increasing general pattern in both compressive and tensile strengths with an increasing AC content, the percentage of AC replacements in the concrete mixtures has a significant effect on the compressive strength of the concrete mixtures, which results in early high strength. The mixture with the highest AC replacement percentage presents the highest increase in compressive strength at early and later ages. This shows that as the AC content increases, the strength gain increases over time. The highest value of compressive strength (63,67 MPa) was gained for the AC 7 % mix at 90 days. It was observed that the compressive strength of concrete with 3,5 % AC increased by (27,6 %, 13,59 %, and 15,84 %), while that of concrete with 7 % AC increased by (35,42 %, 26,43 %, and 23,75 %) at 7, 28, and 90 days, respectively, compared to the control concrete mixture. There is a prominent increase in tensile strength values, in which a value of about 4,87 MPa was recorded for the AC 7 % mix at 90 days. an overall comparison illustrating that an increase in the compressive strength will result in a similar relative increase in the tensile strength. This reduction in splitting tensile strength of the 3,5 % AC mixture at 90 days may be related to the slow hydration and slow development of the strength. It can be observed that the split tensile strength for the binary blended concrete with 3,5 % AC increases by 11,82 % and 20,24 % at 7 and 28 days, respectively, with a decrease of 3,14 % at 90 days, and for the concrete with 7 % AC, it increases by 45,87 %, 35,88 %, and 17,92 % at 7, 28, and 90 days, respectively. as a result of the impact of adding AC, which was found to be effective on concrete strengthening. The reason for strengthening is due to the reactivity of AC particles with OPC particles during the hydration process. As AC is in fine powder form, it can fill the voids, leading to an improvement in strength.(27) As well, the chemical bond developed in related compounds and combinations also increases the strength.(28) Dr. Kookutla Ramesh(29) finds that compressive strength of concrete increases with alumina addition by an amount of 5 %, 10 %, or 15 % Al₂O₃, this increase is considered to be due to the calcium silicate, which provides a significant contribution to binding power and strength during the hydration of Portland cement concrete (the strengthening phase), whereas calcium aluminate ensures early setting as well as early strength. E. Karamian et al.(10) reported that the addition of 5 % AC alone could increase the strength by 12 %. While adding 12 % to 20 % of the alumina, the addition of 12 % alumina powder increases the compressive strength by 51 % at 28 days. This is explained more clearly by the filler effect of the alumina powder. The pozzolanic reaction can be explained by the behavior of alumina as an activator.(13) From the findings, it can be concluded that the enhancement of strength containing AC particles was probably due to the rapid consumption of calcium hydroxide (CaOH)₂ formed during the hydration of Portland cement,(30) considering significant reactivity of AC particles.

Figure 11. Improvement of compressive strength of concrete mixtures due to replacement of OPC by AC

Figure 12. Improvement of splitting tensile strength of concrete mixtures due to replacement of OPC by AC

Results of Durability Performance

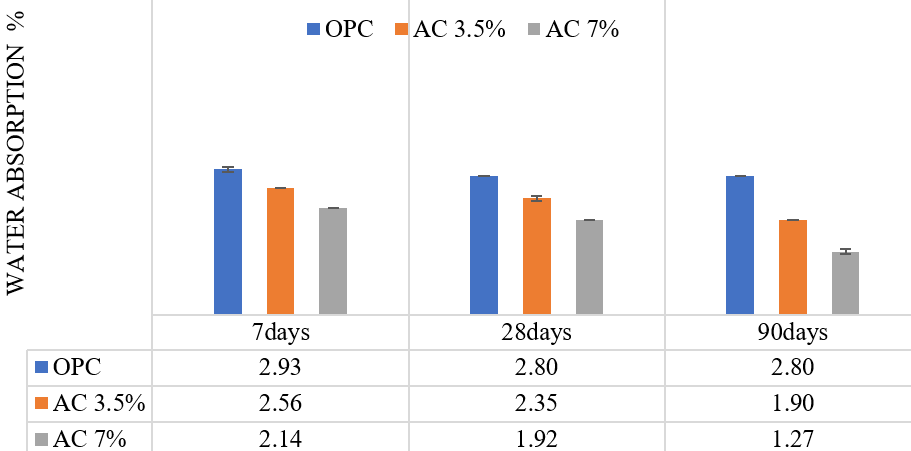

Water Absorption Test

The total water absorption percentage of concrete with AC percentages is illustrated in figure 13. A reduction in water absorption with an increase in curing age was obtained for all mixtures. Water absorption is inversely proportional to compressive strength.(31) The introduction of AC in concrete reduces the water absorption percentage of concrete over age, where the lower percentage (1,27 %) was obtained at 90 days with a 7 % AC mixture. The more AC is used in mixtures, the less water is absorbed. The trend of decrement is 12,63, 16,07, and 32,14 % for AC 3,5 % and 26,96, 31,43, and 54,64 % for AC 7 % at 7, 28, and 90 days, respectively. This degradation in water absorption is due to the ability of alumina particles to fill the voids. As a result, water couldn’t diffuse into the interface bond through capillary action easily, so the water absorption rate was lower compared to the original concrete.(32) It happens due to the larger surface area of Al₂O₃, which is attributed to the excellent interface bonding between the concrete matrix. As mention before that alumina behaves not only as a filler but as an activator also, which supports the pozzolanic process and reacts with the calcium hydroxide generated from the hydration of the calcium silicate. As a result of the use of Al₂O₃ particles, the pore size in the cement matrix was reduced.(33) Mohini Khopade et al.(27) use of 1,75 % alumina, which has reduced the water absorption by 12 % and 48 %, respectively. It is well understood that a lower rate of water absorption leads to better durability properties in concrete. The filler effect of the AC goes back to the reason for water absorption reduction. The reduction in water absorption over age refers to a greater resistance against water absorption in concrete.

Figure 13. Results of Water absorption of concrete mixtures with AC replacement

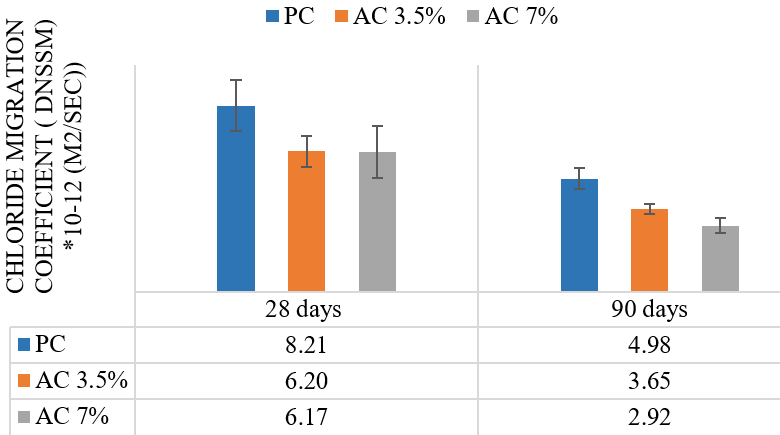

Rapid Chloride Migration Test (RCMT)

Chloride diffusion coefficient along with the non-steady state migration test explained in NT BUILD 492 investigated. In this test, short concrete cylinders were examined to determine chloride migration coefficient Dnssm at 28 and 90 days of age depending on the depth of chloride penetration Xd. For 24 hours, an external electrical potential of 30 V is applied across the specimen, forcing chloride ions from the 10 % NaCl solution to travel into the specimens.

After that, the specimens are axially separated and sprayed with a 0,1 M AgNO₃ solution over newly split slices, and then the chloride diffusion depth Xd is determined. Figure 14 shows the findings of Dnssm values. Results show reduction in values of chloride migration coefficient for all specimens of concrete at 90 days compared with values at 28 days. However, the maximum decreased in Dnssm obtained in case of the mixture incorporated with 7 % AC. For AC additions 3,5 % and 7 % SF the decrease in Dnssm values reach to (23,65 % and 26,9 %) at 28 day and (24,14 % and 41,36 %) at 90 days compared with control concrete respectively. Kookutla Ramesh(29) reported that for 5 %, 10 % and 15 % added alumina content respectively lead to reductions in chloride ingress by 35,06 % for 15 % admixture level at 7 days of curing and by 38,24 % for 15 % admixture level at 14 days of curing, while maximum reduction by 39,83 % in chloride ingress was indicated at 28 days of curing. further by adding alumina in the proportion of 10 to 15 % by wt. of cement, the chloride penetration depth and content reduced considerably.(28) The decrease in RCMT values refers to improve the durability of concrete mixtures. The performance of concrete subjected to aggressive environments suggesting refinement of microstructure leading to improvement in durability and properties of concrete.(34) The diffusion coefficient decreases with an increase of concrete strength.(35) Also a significant relationship between water absorption and chloride migration,(36) this might explained by the findings.

Figure 14. The effect of AC replacement on results of rapid chloride migration test

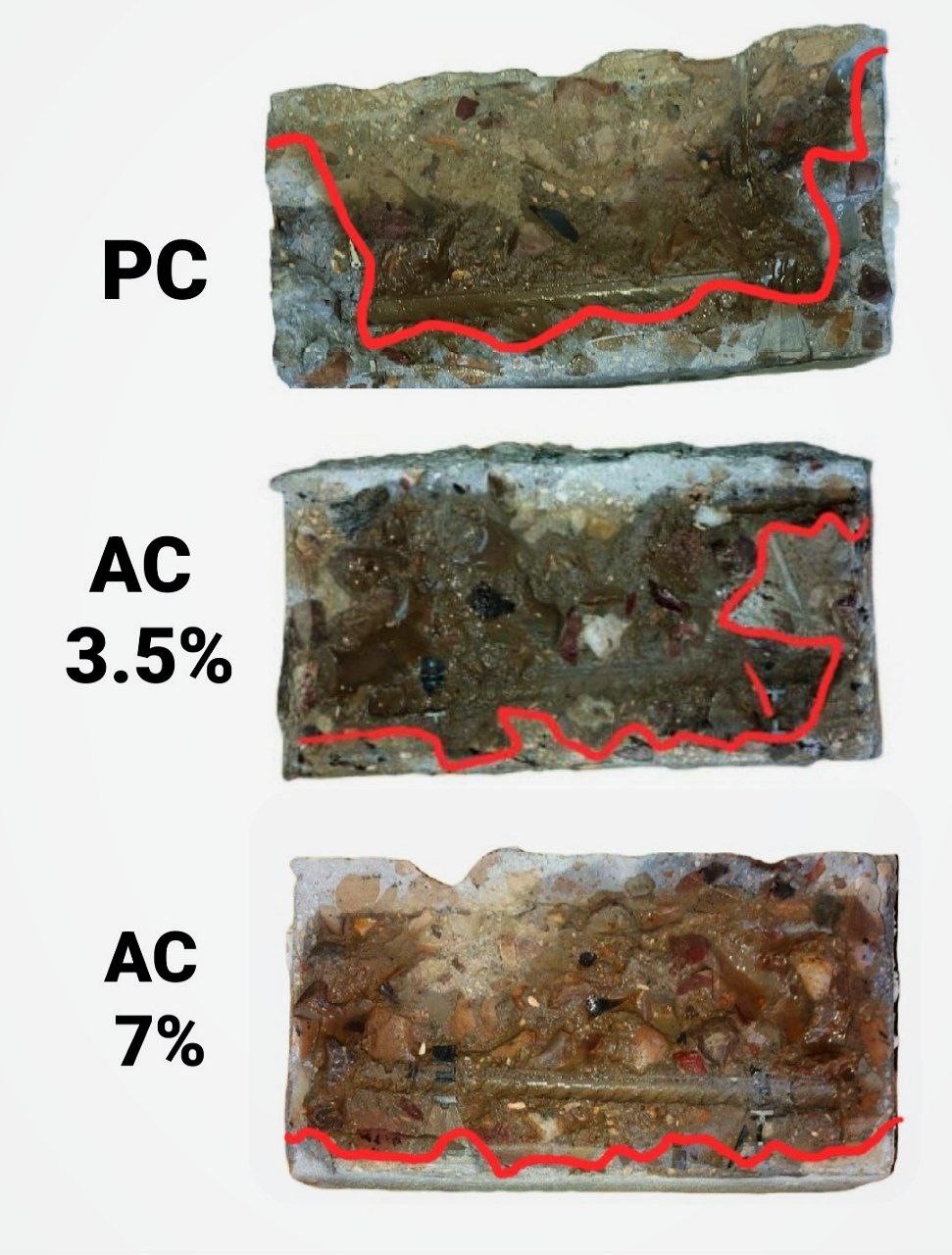

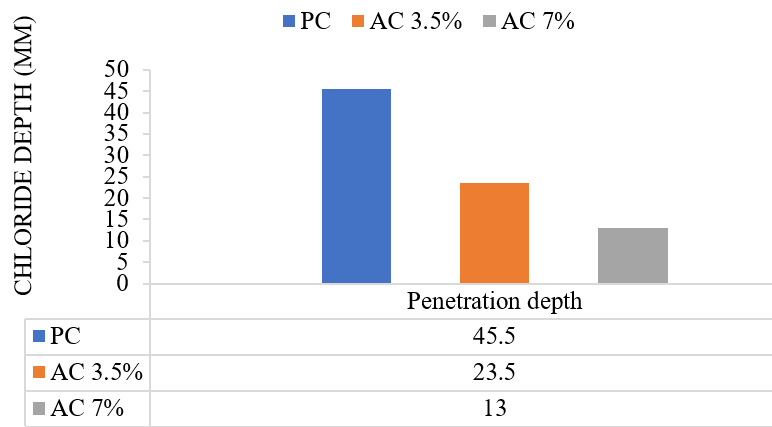

Chloride Penetration

The samples in this test were subjected to a chloride- solution made of 5 % NaCl for 120 days under particular environmental conditions that included drying and wetting cycles. while a water-proofing coating was applied to the other surfaces, the lower surface next to the rebar was not coated and therefore was exposed to the NaCl solution. This test is based on measuring the depth of chloride penetration, represented by the symbol (Xd) after the short prism is sprayed with a particular concentration of 0,1 N silver nitrate (AgNO₃) solution. The reaction between chloride ions (Clˉ) and silver ions (Ag⁺) takes place allowing the measurement of chloride penetration depth (xd) in the prism.(37,38) Figure 16 displays the results for chloride ion penetration depth (xd) for all mixtures, respectively. As presented the reduction in chloride penetration depth was significant with use of sustainable materials, the reduction was (48,35 % and 71,43 %) for 3,5 %AC and, 7 % AC respectively as compared with control concrete at 120 days. The characterization of the concrete resistance against chloride penetration is based on the rapid migration test.(39) However, the chloride diffusion coefficient was obtained give an index reflecting that the ability of the concrete to resist chloride penetration in the same path, see figure 15.

Figure 15. Depths of chloride ion penetration Xd

Figure 16. The effect of AC replacement on results of chloride penetration depth

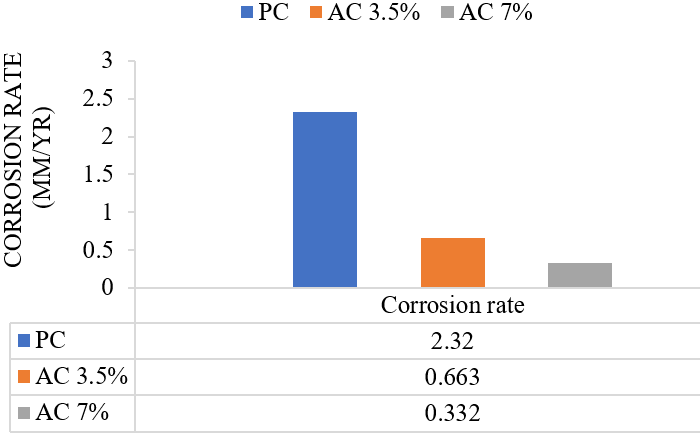

Corrosion Rate (Impressed Current)

The accelerated corrosion test by the impressed current is confirmed to be an adequate method to study the corrosion process in concrete reinforcement. After being subjected to chloride solution and impress current for 26 days, the concrete prisms are carefully fractured to extract the rebar rooted in the concrete, avoiding any damage, and the rebars are cleaned using a sand blast machine. The original concrete mixture achieved the highest corrosion rate when compared to AC mixes, as seen in figure 17. The addition of AC to the concrete mixture takes a longer time to initiate corrosion and cracking; the addition and replacement of AC achieved the least corrosion rate at 7 %. The corrosion rate decreased by 71,42 and 85,68 % for AC 3,5 % and AC 7 %, respectively. M. Sadawy(40) reported that 5 % Al2O3 addition as a cement replacement improves the corrosion resistance and shows the optimum value, while when Al2O3 is added in greater percentages of 5 %, the corrosion resistance decreases but is still higher than original concrete. M. B. Otieno et al.(41) also observed a significant decrease in corrosion rate for concrete made with blended cements compared to OPC concrete. Based on the results obtained, it can be concluded that by increasing the corrosion rate, the chloride ion ingress increases; therefore, chloride-induced corrosion of reinforcing steel affects the mechanical properties of steel and the corrosion products, which easily exceed the limited tensile strength of concrete and cause cracks in concrete, thus decreasing the strength and durability of concrete.(42)

Figure 17. The effect of AC replacement on corrosion rate

Crack width

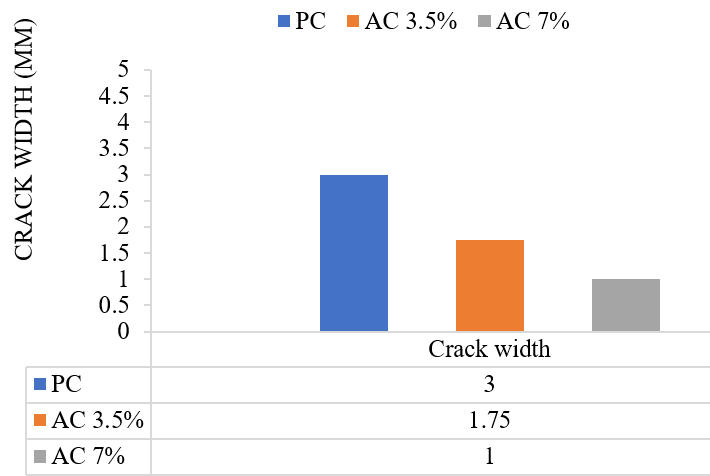

Concrete specimens in which cracking was induced were subjected to impress current. The significance influence of crack width on the maximum chloride penetration depth and the corrosion rate were investigated. The width of the crack were dependence on to the initiation of corrosion in reinforcement concrete.(43) Whereas, the crack width has a more remarkable impact on the corrosion initiation. Also, the crack width is proportional to corrosion steel production and chloride penetration in concrete,(44) which means that as the crack width increases, the chloride penetration also increases. The crack width measurement is illustrated in figure 19. It shows that the crack width tends to decrease steadily with increasing AC content. The crack width decreased by 71,42 and 86,2 % for AC 3,5 % and AC 7 %, respectively. The mixture AC 7 % has the minimum crack width among other mixes. In the presence of cracks, the corrosion resistance of the bars may be the most significant factor affecting the initiation and propagation phases. Cracks mitigate the durability of RC structures by providing special paths for corrosion-inducing chloride (Clˉ) penetration, resulting in rapid initiation and propagation of corrosion in steel and, as a consequence, a significant reduction in durability over time.(41) This leads to the conclusion that, with increasing crack width, the maximum penetration depth increases; leading to a decrease in the durability of concrete and raising the risk of damage to concrete, and vice versa, see figure 18.

Figure 18. Method of measuring the crack width

Figure 19. The effect of AC replacement on crack width caused by impressed current

CONCLUSIONS

Based on the overall findings of this experimental investigation on the behavior of AC in blended concrete systems at two percentages, 3,5 % and 7 %, as a partial replacement for OPC, several conclusions can be drawn:

1. The incorporation of calcined alumina resulted in lower slump flow compared to control concrete, with an increase in water demand.

2. The study demonstrates that incorporating AC into concrete improves strength values and boosts durability at all ages when compared to control concrete.

3. The incorporation of 7 % AC had highest tensile strength and an adequate improvement in compressive strength, with (63,67 MPa) for compressive strength and (4,87 MPa) for tensile strength in 90 days.

4. Calcined alumina reduces water absorption over time, indicating that concrete with AC has a better resistance to water absorption.

5. In terms of chloride ion penetration, corrosion rate, and crack width, the incorporation of AC significantly decreases one another due to an increase in resistance to chloride ingress, which mitigates the influence of cracks on corrosion. While in OPC, the presence of cracks boosts chloride-induced corrosion by boosting concrete penetrability.

RECCOMENDATION

Investigating the behavior and effect of AC with different proportion ratios to determine the optimum proportion for the best performance on concrete strength and durability.Additional study can be carried out on the durability properties of concrete incorporating AC additives, such as acid attack, carbonation, and sulfate attack.

SEM, XRD, and other methods served as means to investigate the microstructural characteristics of concrete containing AC at various ages.

Investigating the impact of hot and cold conditions on the performance of concrete with AC additions.

ACKNOWLEDGMENT

“We sincerely acknowledge Al-Mustaqbal University for covering the publication fees associated with this research. Their support has been instrumental in ensuring the dissemination of our findings to the scientific community. We are grateful for their commitment to advancing scholarly research and promoting academic excellence”.

REFERENCES

1. Odler, “Special Inorganic Cements (1st ed.),” Mod. Concr. Technol., vol. 8, p. 416, 2000, [On-line]. Available: https://doi.org/10.1201/9781482271942

2. Niharika, “PREDICTION OF COMPRESSIVE & FLEXURAL STRENGTHS OF MICRO AL 2 O 3 BLENDED WITH CONCRETE USING ANN,” Int. J. Adv. Res. Eng. Technol., vol. 12, no. 3, pp. 502–510, 2021, doi: 10.34218/IJARET.12.3.2021.047.

3. R. Olar, “Nanomaterials and Nanotechnologies for Civil Engineering,” “Bulletin Polytech. Inst. Iasi - Constr. A, vol. 61, no. 4, pp. 109–117, 2011.

4. Nazari, S. Riahi, S. Riahi, S. F. Shamekhi, and A. Khademno, “Influence of Al2O3 nanoparticles on the compressive strength and workability of blended concrete,” J. Am. Sci., vol. 6, no. 5, pp. 6–9, 2010.

5. J. Kiennemann, E. Chabas, C. Ulrich, and D. Dumont, “the Role of Granulometry and Additives in Optimising the Alumina Matrix in Low Cement Castables .,” vol. 1, pp. 2–5, 2017.

6. Y. WANG and J. GAO, “Effect of MgO and Al2O3 on High-temperature Stability Performance of High-alumina Cement,” Mater. Sci., pp. 1–19, 2023, doi: 10.5755/j02.ms.33912.

7. S. Debbarma, G. D. R. N. Ransinchung, and M. Dhaka, “Effects of a Portland cement additive rich in SiO 2 and Al 2 O 3 in microstructure densification of RAP incorporated RCCP mixes,” Constr. Build. Mater., vol. 258, p. 119626, 2020, doi: 10.1016/j.conbuildmat.2020.119626.

8. R. Sarkar and A. Parija, “Effect of alumina fines on high alumina self-flow low cement casta-bles,” Refract. World Forum, vol. 6, no. 1, pp. 73–77, 2014.

9. S. Li, Z. Jin, and Y. Yu, “Chloride binding by calcined layered double hydroxides and alumina-rich cementitious materials in mortar mixed with seawater and sea sand,” Constr. Build. Ma-ter., vol. 293, p. 123493, 2021, doi: 10.1016/j.conbuildmat.2021.123493.

10. E. Karamian, M. Faghih, M. Parastegari, A. Materials, N. Branch, and I. Azad, “The Effect of Carbon Nanoparticles and Calcined Alumina on Mechanical Properties and Corrosion Resistan-ce Behavior of the Magnesia Carbon Refractories,” vol. 11, pp. 23–27, 2014.

11. F. Van Der Vurst, E. Ghafari, D. Feys, and G. De Schutter, “Influence of addition sequence of materials on rheological properties of self-compacting concrete,” XXII Nord. Concr. Res. Symp. Proc., vol. 50, no. AUGUST, pp. 399–402, 2014, doi: 10.13140/2.1.1153.9846.

12. H. Shokravi, S. E. Mohammadyan-Yasouj, S. S. R. Koloor, M. Petrů, and M. Heidarrezaei, “Ef-fect of alumina additives on mechanical and fresh properties of self-compacting concrete: A review,” Processes, vol. 9, no. 3, pp. 1–22, 2021, doi: 10.3390/pr9030554.

13. U. I. Tofail, “The effect of the addition of Alumina powder on the confinement properties of a cement mortar,” vol. 01055, pp. 1–6, 2018.

14. 2019. Iraqi specification IQ.S. No 5(2019), Portland cement. Central Organization for Stan-dardization and Quality Control, “No Title,” Iraqi Specif., 2019.

15. 1984.. Iraqi specification IQ.S. No 45(1984), Natural aggregate used in concrete. Central Or-ganization for Standardization and Quality Control, “No Title,” Iraqi Specif., 1984.

16. ASTM C494, “ASTM C494/C949M-19: Standard specification for chemical admixtures for con-crete,” Astm C494, no. January, pp. 1–10, 2015.

17. C. 211, “Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Con-crete ACI 211.1-91,” ACI Comm. Reports, Guid. Stand. Pract. Comment., no. 9, pp. 120–121, 2006.

18. “Testing fresh concrete - BS EN 12350-8 Part 8: 2019 - Slump flow test,” BSI Stand. Publ., pp. 5–8, 2019, [Online]. Available: https://www.en-standard.eu/din-en-12350-2-testing-fresh-concrete-part-2-slump-test/%0Ahttps://bsol.bsigroup.com/Home

19. British Standards Institute, “BS EN 12390-7:2000 Testing hardened concrete — Part 7: Density of hardened concrete,” BSI Stand. Publ., vol. 3, no. 1, p. 13, 2000.

20. “BS EN 12390-7 part7-density of hardened concrete,” BSI Stand. Publ., 2019, [Online]. Availa-ble: https://www.scribd.com/document/500514501/BS-EN-12390-7-2019

21. “BS EN 12390-6-2009 - Testing Hardened Concrete Part 6 - Tensile Splitting Strength of Test Specimens,” BSI Stand. Publ., [Online]. Available: https://www.scribd.com/document/500032069/BS-EN-12390-6-2009-Testing-hardened-concrete-Part-6-Tensile-splitting-strength-of-test-specimens

22. NORDTEST ISSN 0283–7153, “Concrete, mortar and cement-based repair materials: Chloride migration coefficient from non-steady-state migration experiments,” Measurement, pp. 1–8, 1999.

23. F. He, C. Shi, Q. Yuan, C. Chen, and K. Zheng, “AgNO3-based colorimetric methods for measu-rement of chloride penetration in concrete,” Constr. Build. Mater., vol. 26, no. 1, pp. 1–8, 2012, doi: 10.1016/j.conbuildmat.2011.06.003.

24. S. Hong et al., “Determination of impressed current efficiency during accelerated corrosion of reinforcement,” Cem. Concr. Compos., vol. 108, no. September 2019, p. 103536, 2020, doi: 10.1016/j.cemconcomp.2020.103536.

25. W. Zhang, C. Junyu, and X. Luo, “Effects of impressed current density on corrosion induced cracking of concrete cover.” Construction and Building Materials, pp. 213–223, 2019.

26. M. Seifan, S. Mendoza, and A. Berenjian, “A comparative study on the influence of nano and micro particles on the workability and mechanical properties of mortar supplemented with fly ash,” Buildings, vol. 11, no. 2, pp. 1–17, 2021, doi: 10.3390/buildings11020060.

27. M. Khopade and S. V Desale, “Study of Properties of Self-Compacting Concrete with Cement replaced with Aluminum Oxide and Silica Fume,” vol. 8, pp. 767–774, 2020.

28. K. Ramesh, “An Experimental Study on Effect of Aluminum Oxide on Strength and Corrosion Resistance of Concrete,” Int. J. Eng. Res. Technol., vol. 3, no. 11, pp. 269–271, 2016.

29. B. R, S. Abdullah Al Wahaibi, and A. N, “An Experimental Study on Effect of Aluminum Oxide on Strength and Corrosion Resistance of Concrete,” Int. J. Eng. Res. Technol., vol. 3, no. 11, pp. 14–19, 2014, doi: 10.53555/eijse.v3i1.39.

30. KiachehrBehfarnia and NiloofarSalemi, “The effects of nano-silica and nano-alumina on frost resistance of normal concrete,” Constr. Build. Mater., vol. 48, pp. 580–584, 2013.

31. R. Alconpat, “Correlations between water absorption, electrical resistivity and compressive strength of concrete with different contents of pozzolan,” vol. 9, no. 2, pp. 152–166, 2020.

32. R. Kumar, K. Singh, E. Gogna, H. R. Sinha, and A. K. Sahoo, “Comparative analysis of mecha-nical and water absorption properties of nano/micro-sized alumina filler-based glass-jute hybrid composites,” Int. J. Integr. Eng., vol. 12, no. 4, pp. 104–115, 2020.

33. Nazari and S. Riahi, “Abrasion resistance of concrete containing SiO2 and Al2O3 nanoparticles in different curing media,” Procedia Eng., vol. 43, pp. 2939– 2946, 2001.

34. G. D. Ransinchung, B. Kumar, and V. Kumar, “Assessment of water absorption and chloride ion penetration of pavement quality concrete admixed with wollastonite and microsilica,” Constr. Build. Mater., vol. 23, no. 2, pp. 1168–1177, 2009.

35. S. Yup, B. Sung, and B. Hwan, “Cement and Concrete Research Effect of crack width on chlo-ride diffusion coef fi cients of concrete by steady-state migration tests,” Cem. Concr. Res., vol. 41, no. 1, pp. 9–19, 2011, doi: 10.1016/j.cemconres.2010.08.018.

36. G. De Schutter, “Evaluation of water absorption of concrete as a measure for resistance aga-inst carbonation and chloride migration,” no. January, 2014, doi: 10.1007/BF02483288.

37. X. A. and B. T. He, F., C. Shi, Q. Yuan, “‘Calculation of chloride concentration at color change boundary of AgNO3 colorimetric measurement’.,” Cem. Concr. Res. 41(11) 1095-1103., 2011.

38. F. He, C. Shi, Q. Yuan, C. Chen, and K. Zheng, “‘AgNO3-based colorimetric methods for mea-surement of chloride penetration in concrete,’” Constr. Build. Mater. 26(1) 1-8., 2012.

39. O. E. Gjørv, “Durability of Concrete Structures,” no. 123, pp. 151–172, 2011, doi: 10.1007/s13369-010-0033-5.

40. M. M. Sadawy, “Effect of Al2O3 additives on the corrosion and electrochemical behavior of steel embedded in ordinary Portland cement concrete,” Am. J. Mater. Res. Am. J. Mater. Res., vol. 1, no. 4, pp. 53–58, 2014, [Online]. Available: http://www.aascit.org/journal/ajmr

41. M. B. Otieno, M. G. Alexander, and H. Beushausen, “Corrosion in cracked and uncracked con-crete – influence of crack width , concrete quality and crack reopening,” Mag. Concr. Res., vol. 9831, no. 6, pp. 393–404, 2010, doi: 10.1680/macr.2010.62.6.393.

42. C. I. Khan, R. François, “Mechanical behavior of longterm corroded reinforced concrete be-am.,” Proc. Jt. fib-RILEM Work. held Madrid, Spain, vol. 22, pp. 243-259., 2010.

43. W. Li, W. Liu, and S. Wang, “The Effect of Crack Width on Chloride-Induced Corrosion of Steel in Concrete,” Adv. Mater. Sci. Eng., vol. 2017, 2017, doi: 10.1155/2017/3968578.

44. C.-M. Aldea, S. P. Shah, and A. Karr, “Effect of cracking on water and chloride permeability on concrete,” ournal Mater. Civ. Eng., vol. 11, no. 3, pp. 181–187., 1999.

FINANCING

The authors did not receive financing for the development of this research.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

AUTHORSHIP CONTRIBUTION

Conceptualization: Nora AL-Anssari, Abbas AL-Ameeri.

Data curation: Nora AL-Anssari, Abbas AL-Ameeri.

Formal analysis: Nora AL-Anssari, Abbas AL-Ameeri.

Research: Nora AL-Anssari, Abbas AL-Ameeri.

Methodology: Nora AL-Anssari, Abbas AL-Ameeri.

Drafting - original draft: Nora AL-Anssari, Abbas AL-Ameeri.

Writing - proofreading and editing: Nora AL-Anssari, Abbas AL-Ameeri.