Category: STEM (Science, Technology, Engineering and Mathematics)

ORIGINAL

On the Post-Heat Behavior of Cement Mortar Containing Mechanically Modified Ground Coal Bottom Ash

Comportamiento post-calefacción del mortero de cemento con cenizas de fondo de carbón modificadas mecánicamente

Mohammad I. Al Biajawi1 *, Rahimah Embong1 *, Khairunisa Muthusamy1 *, Haneen Abdel Jabar1 *, Nahla Hilal2 *, Fadzli Mohamed Nazri3 *

1Faculty of Engineering Technology, Universiti Malaysia Pahang, Pahang 26300, Malaysia.

2Scientific Affairs Department, University of Fallujah, Baghdad, Iraq.

3School of Civil Engineering, Engineering Campus, Universiti Sains Malaysia, Nibong Tebal, Penang 14300, Malaysia.

Cite as: Al Biajawi MI, Embong R, Muthusamy K, Jabar HA, Hilal N, Nazri FM. On the Post-Heat Behavior of Cement Mortar Containing Mechanically Modified Ground Coal Bottom Ash. Salud, Ciencia y Tecnología - Serie de Conferencias. 2024; 3:813. https://doi.org/10.56294/sctconf2024813

Submitted: 19-01-2024 Revised: 27-03-2024 Accepted: 30-05-2024 Published: 31-05-2024

Editor: Dr.

William Castillo-González ![]()

Note: Paper presented at the 3rd Annual International Conference on Information & Sciences (AICIS’23).

ABSTRACT

Coal is widely recognized as a significant and essential fuel source due to its capacity to undergo combustion and produce heat in many different regions worldwide. Over the course of many decades, there has been a notable rise in power usage among individuals, thus resulting in an upsurge in the utilization of coal. The growth of mankind has a parallel rising trajectory with the utilization of cement in the building industry, as well as a corresponding rise in cement manufacturing. These two phenomena significantly contribute to the escalation of carbon dioxide (CO2) emissions and the improper disposal of coal ash, both of which pose significant environmental hazards. Coal-fired thermal power plants generate many waste products from industry, including coal-bottom ash (CBA), which may be effectively used in the production of mortar or concrete. This practice not only promotes the adoption of sustainable construction materials but also encourages the utilization of these wastes. In contrast, it is worth noting that cement manufacture yields a significant quantity of carbon dioxide emissions, so exerting a detrimental influence on the ecosystem. The reduction of environmental deterioration may be achieved by substituting cement with waste products. The substitution of Portland cement with reutilized coal combustion products has the potential to provide significant environmental and infrastructural advantages. This study presents an experimental investigation into the post-heat performance of cement mortars including ground coal bottom ash (CBA). To achieve this objective, an investigation was conducted to assess the strength qualities, residual strength, and mass losses of mortar specimens. These specimens comprised varying proportions (10 %, 20 %, 30 %, and 40 %) of CBA as a substitute for cement. To perform the heating procedure, samples were subjected to temperatures of 200°C, 400°C, and 600°C, which corresponded to room temperatures. The findings indicate that the use of ground CBA up to a proportion of 20 % yields mortar with the maximum value of compressive strength compared with the control sample. The use of a substantial amount of ground CBA has been shown to produce the most significant reduction in mass and decrease in strength when subjected to high temperatures. As a result, the residual strength of concrete experiences a decrease of 33,65 % when exposed to a temperature of 600°C in conventional concrete while for CBA in concrete decreases around 40,9 %. In general, the integration of ground CBA alternatives as an alternative to cement would result in a decrease in the need for the manufacture of cement and the environmental pollution associated with CBA discharge.

Keywords: Mortar; Coal Bottom Ash (CBA); Heating Temperatures; Strength Properties; Cement Replacement; Strength Properties.

RESUMEN

El carbón es ampliamente reconocido como una fuente de combustible importante y esencial debido a su capacidad para someterse a combustión y producir calor en muchas regiones diferentes de todo el mundo. A lo largo de muchas décadas, se ha producido un notable aumento del uso de la energía entre los individuos, lo que ha dado lugar a un incremento de la utilización del carbón. El crecimiento de la humanidad tiene una trayectoria ascendente paralela a la utilización de cemento en la industria de la construcción, así como el correspondiente aumento de la fabricación de cemento. Estos dos fenómenos contribuyen significativamente a la escalada de las emisiones de dióxido de carbono (CO2) y a la eliminación inadecuada de las cenizas de carbón, que suponen importantes peligros para el medio ambiente. Las centrales térmicas de carbón generan muchos residuos industriales, entre ellos las cenizas de fondo de carbón (CBA), que pueden utilizarse eficazmente en la producción de mortero u hormigón. Esta práctica no sólo promueve la adopción de materiales de construcción sostenibles, sino que también fomenta la utilización de estos residuos. En cambio, cabe señalar que la fabricación de cemento produce una cantidad importante de emisiones de dióxido de carbono, por lo que ejerce una influencia perjudicial sobre el ecosistema. La reducción del deterioro medioambiental puede lograrse sustituyendo el cemento por productos de desecho. La sustitución del cemento Portland por productos de combustión de carbón reutilizados tiene el potencial de proporcionar importantes ventajas medioambientales y de infraestructuras. Este estudio presenta una investigación experimental sobre el comportamiento post-calentamiento de morteros de cemento que incluyen cenizas de fondo de carbón molidas (CBA). Para lograr este objetivo, se llevó a cabo una investigación para evaluar las cualidades de resistencia, la resistencia residual y las pérdidas de masa de los especímenes de mortero. Estas probetas contenían proporciones variables (10 %, 20 %, 30 % y 40 %) de CBA como sustituto del cemento. Para llevar a cabo el procedimiento de calentamiento, las muestras se sometieron a temperaturas de 200°C, 400°C y 600°C, que correspondían a la temperatura ambiente. Los resultados indican que el uso de CBA molido hasta una proporción del 20 % produce un mortero con el valor máximo de resistencia a la compresión en comparación con la muestra de control. Se ha demostrado que el uso de una cantidad considerable de CBA molida produce la reducción más significativa de la masa y la disminución de la resistencia cuando se somete a altas temperaturas. Como resultado, la resistencia residual del hormigón experimenta una disminución del 33,65 % cuando se expone a una temperatura de 600°C en el hormigón convencional, mientras que para la CBA en el hormigón disminuye alrededor del 40,9 %. En general, la integración de alternativas de CBA molida como alternativa al cemento supondría una disminución de la necesidad de fabricación de cemento y de la contaminación ambiental asociada al vertido de CBA.

Palabras clave: Mortero; Ceniza de Fondo de Carbón (CBA); Temperaturas de Calentamiento; Propiedades Resistentes; Sustitución del Cemento; Propiedades Resistentes.

INTRODUCTION

Concrete is frequently employed as a principal component of structure in all kinds of construction owing to its various advantages in comparison to other materials, such as its high compressive strength, outstanding strength, simplicity of manufacture, and inherent non-combustible properties.(1,2,3) Concrete constructions must satisfy several criteria, including safety, structural performance, durability, and adherence to elevated temperature norms, as outlined in construction requirements. Elevated temperatures are seen as a major potential hazard in most constructions and constructions.(4,5) Elevated temperatures exposure induces a sequence of both physical and chemical transformations in concrete, which substantially diminishes its mechanical properties.(6,7) The resulting modifications include the disintegration of hydration products and aggregates, loss of water, an increase in permeability and grinding of the substructure. Consequently, a more comprehensive understanding of the fundamental components of concrete, including cement, as well as its response to elevated temperatures, is necessary.(8,9) Several years of scientific research and practical application have established that structures constructed using concrete are more resistant to high temperatures than those made from alternative materials. The compressive strength of the concrete remains unaffected by temperatures that are under 300°C.(9,10) Significant alterations, nevertheless, are anticipated beyond this temperature threshold. The observed alterations may be ascribed to the degradation of hydrated cement, degradation of aggregates, and thermal inconsistencies among components of the concrete, which lead to the accumulation of tension and the formation of microcracks. In addition, it is observed that the pore size of cement paste expands due to the degradation of Ca(OH)2 and C-S-H, hence contributing to the decline in compressive strength at elevated temperatures.(11,12)

In contemporary times, there has been a growing interest among investigators in the concrete industry regarding the enhancement of concrete’s fire resistance using silica derived from pozzolanic minerals.(13) Based on their research findings, the substitution of cement with pozzolanic elements emerges as a very effective strategy for enhancing the fire-resistant properties of concrete.(13,14) The pozzolanic responses serve to enhance the strength and durability of cement paste, mortar, and concrete by reducing accessibility and producing more calcium silicate hydrates (C-S- H) gel through the chemical reaction that occurs of silicon dioxide (SiO2) from the pozzolanic substances with the Ca(OH)2 of mortar. The pozzolanic materials that are frequently employed include silica fume (SF), fly ash (FA), metakaolin (MK), and CBA.(15,16)

Consequently, there has been a current increase in the number of investigators intrigued by the possibility of producing concrete with enhanced fire resistance, which can be achieved through the aforementioned methods. Implementing pozzolanic materials instead of cement, such as FA(13), CBA(17), silica fume(18), or slag(19), is an exceptionally effective strategy. The incorporation of industrial waste products, such as alternative materials, in the composition of a concrete mixture has been discovered to possess significant applicability.(20) The positive impact of pozzolanic materials, such as FA, silica fume, silica flour, metakaolin, and powdered granulated blast furnace slag, on resisting high temperatures is attributed to the stabilization of calcium hydroxide (Ca(OH)2) generated during the hydration of cement by the process of pozzolanic reactions.(21,22) The adverse impacts of Ca(OH)2 manifest in the form of micro-cracks, which mostly emerge in regions with higher concentrations of Ca(OH)2 at around 300 °C. This occurrence may be attributed to the breakdown of calcium hydroxide into lime and water vapor which occurs at 350°C.(23,24) Degradation of calcium hydroxide does not significantly contribute to the reduction in strength when subjected to high temperatures. Nevertheless, this phenomenon has the potential to cause significant structural harm because of the expansion of lime during the cooling phase. The occurrence of such damage may also be seen in the process of fire suppression, whereby calcium oxide (CaO) undergoes a reaction with water, resulting in the formation of calcium hydroxide (Ca(OH)2) accompanied by a substantial increase in volume.(25,26)

CBA and FA are supplementary substances that are generated by the combustion of coal in electricity-generating facilities.(27) Previous studies have revealed the applications of CBA in mortars and concretes in other research works. Primarily, (FA) is used as an ingredient of Portland cement, serving as a supplemental cementitious material (SCM) in concrete by substituting cement.(28) Additionally, it finds application as a subbase material in highways and serves several other beneficial purposes.(29) In addition, CBA is used as an aggregate in concrete mixtures, among various secondary uses, or alternatively, it is deposited at designated waste disposal sites.(30) Recent research conducted by Park et al.(31) has shown that the determinants of coal ash reuse are mostly influenced by company decision-making behaviors, rather than market or institutional considerations. The pozzolanicity of FA is attributed to its composition of silica, alumina, and iron oxide. Additionally, fly ash exhibits an additive influence when used in mortars and concretes. In certain types of concrete, the impact of the filler material is seen to be more pronounced compared to the influence of pozzolanic material. Kiattikomol et al.(32) assert that the primary factor influencing the pozzolanicity of FA is its fineness, surpassing even its chemical makeup in significance. Previous research(33,34) investigations have shown the influence of FA fineness on compressive strength. The compressive strength of ground fly ash mortars was found to be superior to that of mortars made with coarse ashes during the early stages of curing. As a result, the use of ground CBA has the potential to enhance the density of mortars and concretes. Nevertheless, the use of CBA as a viable alternative to cement not only serves to minimize the emissions of carbon dioxide and other greenhouse gases but also fosters ecological practices within the building industry and enhances the efficient utilization of land resources.(35,36) Consequently, the intent of the current research is to examine the impact of employing CBA partially as a substitute for cement on the prevention of strength retrogression in cemented mortar subjected to temperatures upwards of 600°C. This paper reveals original experimental results about the use of CBA as a preventative strategy toward strength retrogression in hardened mortar exposed to high temperatures. The inclusion of CBA leads to alterations due to high- temperature exposure, resulting in data on the mechanical characteristics of the materials, both before and postexposure.

Research Significance

Contemporary building techniques need the substitution of cement with environmentally sustainable materials that include reduced energy consumption throughout their manufacturing process. Within this specific instance, it is conceivable for a waste product from industry to function as a viable alternative to typical Portland cement throughout the process of mortar production. Furthermore, research into the enhancement of novelty and strength properties through the utilization of industrial turn down as a partial cement replacement in the production of mortar has yet to be investigated and is not yet published. In mortar or concrete production, nevertheless, the incorporation of industrial waste products such as CBA as a partial substitute for cement may enhance the strength characteristics. Besides, the incorporation of CBA as a partial substitute for cement could result in a reduction in cement usage, thereby leading to a decrease in the emission of carbon dioxide into the environment. The intent of this research is to examine the impact of CBA as a partial substitute for cement on the mitigation of strength degradation in hardened mortar when exposed to extreme temperatures of up to 600°C. This paper reveals significant experimental results regarding the use of CBA as a preventative strategy against strength retrogression in hardened cement paste and mortar exposed to high temperatures. The introduction of CBA leads to changes in high- temperature exposure, resulting in fresh data on the mechanical characteristics of the materials, both pre-and postexposure. This experimental attempt is anticipated to contribute to the expanding construction industry’s quest for an environmentally friendly growth that preserves natural resources. In addition, the insights gained from this research can encourage civil engineers to utilize industrial byproducts and facilitate the application of that understanding to concrete structures for the purpose of ensuring their sustainability and safety.

Experimental Work

The experimental work consists of three stages that involve provision of material used, and preparation of mortar specimens’ mixture and, finally with testing of mortar samples. The following subsection will explain this in detail.

Materials

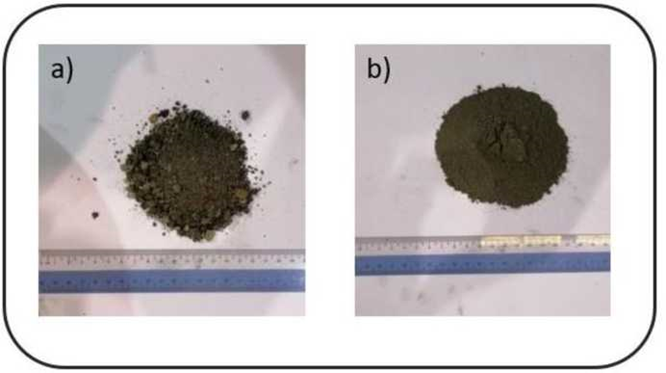

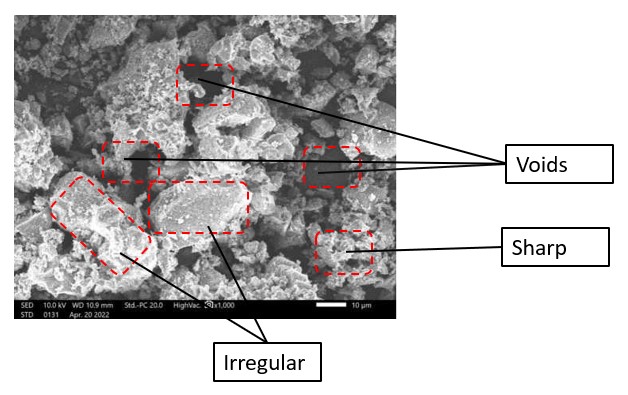

In this experimental work, ordinary Portland cement (OPC) with a specified surface area of 0,866 m2/g. was employed (YTL ORANG KUAT) MS EN 197-1 CEM I 52,5 N (which following EN 197-1). The OPC was used for experimental purposes and prior to testing various properties as MS EN 197-1 and to establish various EN 197-1 limitations. The river sand aggregate employed in this study met the requirements of ASTM C778-13.(37) The specific gravity, water absorption, and fineness modulus of the sand were 2,66, 1,75, and 3,80, respectively. To remove any trace of moisture from the river sand used for these applications, it was first dried in an oven for 24 h at a temperature of 110± 5 C. After that, it was sieved with a No. 2,36 mm sieve and left on a No. 1,18 mm sieve for further processing. It is possible to use the processed river sand directly for mixing the mortar. The original CBA was collected from a thermal plant in Johor, Malaysia. It was visually observed that the original CBA is mostly coarser, porous in nature, and in appearance like a volcanic material, as shown in figure 1a and figure 1b, which shows the ground CBA used as cement replacement in mortar mixture. The SEM image of CBA, as presented in figure 2, shows that it has irregular, sharp, spherical, and porous particles, and a mix of multiple textures.

Figure 1. a) Original CBA and b) Ground CBA

Figure 2. SEM morphology of CBA

The CBA was dried in an oven at a temperature of 110±5 OC for 24 hours, then was sieved through 300-micron sieve, after that was placed in the Los Angeles machine for 5000 cycle, to be suitable pozzolanic materials as recommended guidelines in ASTM C618.(38) The chemical compositions of CBA and OPC are provided in table 2, which shows that CBA meets the requirements of ASTM C618(38) and is classified as class F ash. Furthermore, the physical properties of CBA are illustrated in table 1. The color of CBA changed from original to ground CBA. The original CBA has a gray color and because of grinding, it changes from gray to dark gray in color.

|

Table 1. Physical properties of cement |

||

|

Physical properties |

Cement |

CBA |

|

Bulk density (kg/m3) |

1440 |

2350 |

|

specific gravity (g/cm3) |

3,15 |

2,21 |

|

Blaine surface area (m2/g) |

0,867 |

0,494 |

|

Fineness modulus |

3,38 |

2,19 |

|

Water absorption (%) |

-- |

5,30 |

|

Color |

Gray |

Blackish or dark gray |

|

Table 2. Chemical composition of cement and CBA |

||

|

Chemical composition (%) |

Cement |

Coal bottom ash (CBA) |

|

Silicon Dioxide |

14,4 |

50,8 |

|

Aluminum Oxide |

3,55 |

14,2 |

|

Ferric Oxide |

3,10 |

16,6 |

|

Sulphur Trioxide |

3,17 |

0,460 |

|

Calcium Oxide |

63,8 |

11,2 |

|

Magnesium oxide |

0,693 |

1,55 |

|

Potassium Oxide |

0,818 |

1,66 |

|

Titanium Dioxide |

0,228 |

1,30 |

|

Loss of ignition |

2,20 |

3,90 |

Mix Design Specimen Preparation

Table 3 below presents the material compositions of the mortar mixes that were made and tested as part of this study. Mortar mixture was designed with grade 35 MPa which is suitable to be used in various construction applications. A total of six different mortar mixes were prepared, each having a ratio of 1:2,59:0,50 for the cement, sand, and water-cement ratios and a ratio of 0,58 for the water-binder ratio. Mortar ingredients containing CBA were prepared with CBA contents of 10 %, 20 %, 30 %, 40 %, and 50 % mass replacement of OPC. In the combinations used as reference, OPC was the only binder used. Therefore, the different types of mortar mixtures used as samples were labeled as follows: 0, 10 %, 20 %, 30 %, 40 %, and 50 %, respectively. Before starting to prepare the sample, each of the required raw materials was measured and weighed with high precision. To prepare the samples, the components were first mixed in a small blender. However, to ensure continuity and homogeneity of the concrete samples, the materials were mixed gradually. After adding the fine to the drum mixer and stirring for 3 min, the next step was to mix in the binders (OPC and CBA) according to the mixing schedules for another 3 min. After adding water, the ingredients were mixed for another 3 min. The freshly mixed concrete was poured into the mold and allowed to rest for a full day. For each experiment, three samples were prepared that corresponded to the mixture composition and were part of the experiment. After a period of 24 hours, the samples were removed from the molds and immediately placed in water to allow them to harden in water before being tested. The ambient temperature in the laboratory was between 25 and 30°C, and the relative humidity was between 70 and 80 %.

|

Table 3. Mix proportion of mortar mixes (Kg/m3) |

|||||

|

Mixes (%) |

W/C ratio |

Cement (Kg/m3) |

Fine Aggregate (Kg/m3) |

Water (Kg/m3) |

CBA (Kg/m3) |

|

0 |

0,50 |

530 |

1375 |

270 |

- |

|

10 |

0,50 |

477 |

1375 |

270 |

53 |

|

20 |

0,50 |

424 |

1375 |

270 |

106 |

|

30 |

0,50 |

371 |

1375 |

270 |

159 |

|

40 |

0,50 |

318 |

1375 |

270 |

212 |

|

50 |

0,50 |

265 |

1375 |

270 |

265 |

Testing producer

The evaluation of the compressive strength of mortar containing CBA as a substitute to cement was conducted through the implementation of a compressive strength test. The compressive strength was evaluated by incorporating mortar cubes with the following dimensions: 50 mm X 50 mm X 50 mm. A hydraulic-mechanical movement mechanism was used to apply a calibrated compressive load. The evaluation of compressive strength was conducted in accordance with the ASTM C109/C109 standard.(39) The experiment was conducted on specimens that had undergone a curing process for a duration of 28 days. To ensure accurate outcomes for each test, three mortar cube samples were used to represent each mortar mix type. The experiment was conducted on specimens that had undergone a curing period of 28 days, both before and after being subjected to extreme temperatures. To ensure accuracy in the results, three mortar cube specimens were used for each test, representing each variety of mortar. The evaluation of water absorption is an essential characteristic to consider for cement-based composites, especially in submerged conditions since it directly impacts the adaptability of these composites. The experiment was conducted in compliance with the specifications given in ASTM C642-21.(40) The concrete samples underwent a drying process in an oven for a period of 72 hours at a temperature of 105 ± 5°C. This was done to achieve a uniform density after the specified duration of curing. The samples were weighed subsequent to the process of drying. Following this, the samples were submerged in water for a duration of 28 days. The samples were re-weighed after a period of 28 days in order to determine the extent of water absorption. This was calculated using the formula: water absorption = (Ww - Wd) / Wd x 100, where Dw represents the dry weight of the specimen and Ww represents the wet weight of the sample.

Heating Process

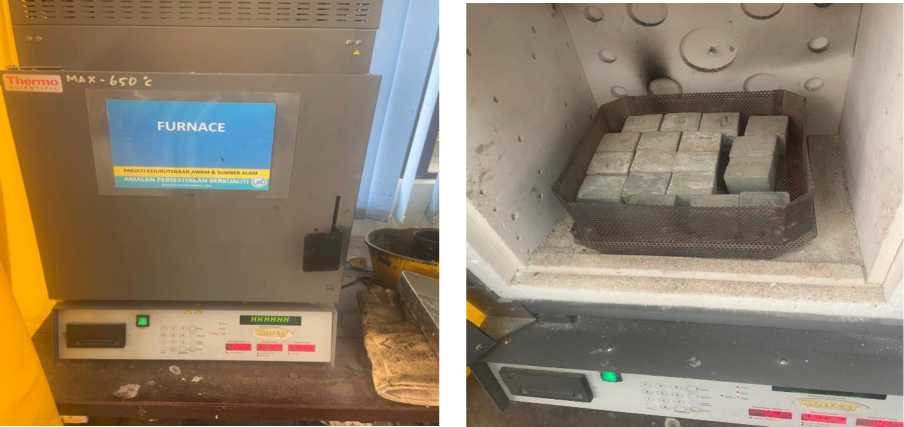

The specimens were removed from the water cure at the 28-day mark and allowed to dry for one day in the laboratory. Subsequently, the concrete samples were dried in an electric oven prior to being subjected to elevated temperatures. Twenty-four hours were spent in an oven preheated to 105°C to dry the water-cured samples in order to prevent unpredictable spalling. The specimens underwent elevated temperatures (200°C, 400°C, and 600°C) at a consistent rate of 10 °C/min in an electric furnace and remained at the desired temperature for 1 h. The initial group, consisting of 18 cube mortar samples (three samples for each composition), was evaluated and employed at ambient temperature (25°C) as a standard of contrast. To evaluate the efficacy of the combinations in a high-risk setting, such as a fire emergency, a fire-resistance test was undertaken. The experiment included selecting three distinct temperature levels (200°C, 400°C, and 600°C) as the designated goal temperatures for testing the materials. The testing procedure adhered to the guidelines outlined by the American Society for Testing and Materials (ASTM) and used an electric furnace. As illustrated in figure 3, an electric furnace was employed for this investigation. In the shutdown furnace, the specimens were subsequently cooled progressively over a period of twenty-four hours. The final specifications included the mass loss and residual compressive strength. It is important to mention that the mean value of the measurements was reported for three specimens from each CBA mixture that were evaluated.

Figure 3. Electric apparatus furnace used for the mortar samples at elevated temperatures

RESULTS AND DISCUSSION

Compressive strength

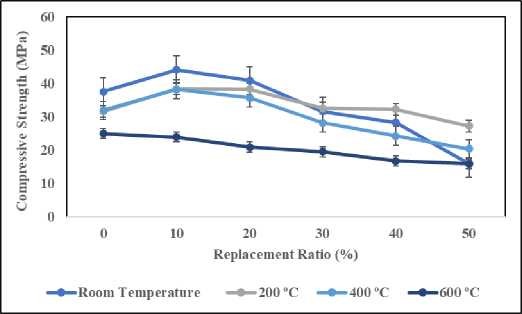

The determination of concrete compressive strength conducted 28 days after the casting and curing process, has substantial importance as a key feature and influential component within the construction sector. Every structural element is developed according to a predetermined compressive strength criterion. Consequently, the construction sector disregards any concrete mixture that fails to fulfil the minimum compressive strength standards. The current investigation included the evaluation of the compressive strength of the mortar mixture by examining 50-mm cubes after a curing period of 28 days. Prior to being subjected to elevated temperatures, the mortars that included a maximum of 20 % CBA as a partial substitute for cement demonstrated superior compressive strength compared with the control samples within the mixture. The data shown in the Fig.4 indicate that the substitution of cement with 30 %, 40 %, and 50 % of CBA resulted in a reduction in compressive strength of 16,021 %, 24,764 %, and 57,559 %, respectively, compared with conventional mortar samples under ambient conditions. On the basis of the obtained data, it is evident that the compressive strength of the control samples, which did not contain any CBA (control samples), exhibited a decline from 37,627 to 15,969 MPa when subjected to room temperature and 600°C, respectively. Furthermore, while considering the utilization of CBA as a partial replacement for cement aggregate at a rate of 10 %, the compressive strength exhibited a drop. Specifically, the compressive strength values were recorded as 44,171 MPa at ambient temperature and 38,198 MPa at 400°C. Furthermore, the substitution of CBA with cement at a rate of up to 20 % resulted in a reduction in compressive strength from 44,171 MPa at ambient temperature to 24,969 MPa at a temperature of 600°C. Increasing the replacement percentage of ground CBA to 50 % resulted in a marginal reduction in compressive strength. However, it should be noted that the strength results obtained from these specimens remain inferior to those of the control samples’ mortars when subjected to increased temperatures of 200°C, 400°C, and 600°C. Based on the findings, it can be seen that the reduction in strength of CBA concrete is greater compared to that of standard concrete. As a result, the residual strength of concrete experiences a decrease of 33,65 % when exposed to a temperature of 600°C in conventional concrete. In contrast, the residual strength of CBA at 10 % replacement mortar decreases by 43,55 % when subjected to a temperature of 600 °C. The compressive strength of concrete exhibited a consistent decrease as the temperature increased in both concrete samples. The disparity in residual compressive strength is shown in Figure 4. Moreover, the current investigation yielded some intriguing findings. Based on the findings, it was seen that all specimens exhibited a significant reduction in strength, retaining from 30 % to 50 % compared to control strength after being subjected to a temperature of 600°C. Nevertheless, it is important to note that the residual strength proportional is significantly elevated in comparison with standard weight concrete subjected to comparable testing conditions, which demonstrate values spanning from 10 % to 50 % of the control strength. These findings are consistent with those of prior research, which also documented a reduction in compressive strength.(41,42)

Figure 4. Compressive strength results of mortars with various replacement ratios of CBA as partial cement replacement at 28 days

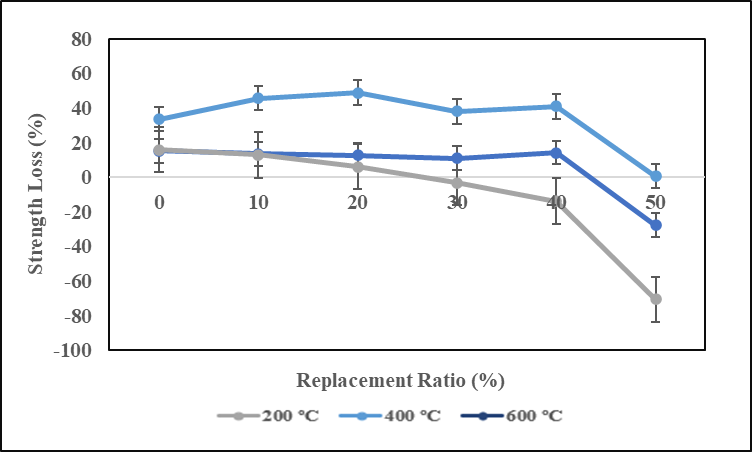

Strength Loss

Figure 5 provides a summary of the compressive strength losses incurred by specimens treated at various elevated temperatures and containing varying proportions of ground CBA. By comparing the 28-day compressive strength at room temperature to variations in compressive strength at elevated temperatures, the latter was identified. The strength loss rises as the proportion of ground CBA substitution and temperatures increase, as depicted in the graph. A raise in the substitution ratio from 10 % to 50 % led to a reduced strength loss at a temperature of 200°C in comparison to the reference specimens. Nevertheless, the mortar supplemented with powdered CBA exhibits a greater reduction in strength up to 400°C in comparison to the control samples. The mortar exhibited a significant reduction in strength when subjected to a temperature of 600°C. At 600°C, these specimens all underwent a near-total loss of vitality. Ma, Qianmin, et al.(43) reported that the delineate three distinct phases in which the compressive strength of concrete diminishes when exposed to elevated temperatures. At 300°C, the compressive strength of concrete remains unchanged or experiences a marginal increase. The strength of the material experiences a considerable drop when subjected to temperatures within the range of 200°C to 600°C. Furthermore, at temperatures beyond 600°C, the strength of the material almost diminishes entirely. The observed phenomenon may be attributed to the thermal degradation of calcium hydroxide (Ca(OH)2) inside the concrete matrix during exposure to temperatures over 200°C.(44) In the context of the impact of ground calcium-based additives (CBA), the excessive use thereof has been seen to diminish the resistance of mortar to increased temperatures.

Figure 5. Loss strength of specimens’ mortar with CBA as partial after exposure to elevated temperatures

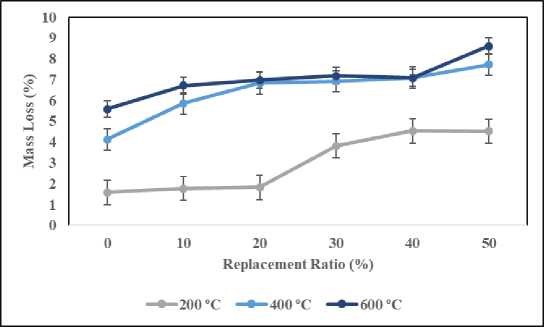

Mass loss

The mass loss test is significant in evaluating the performance of concrete materials when subjected to elevated temperatures. The examination of the mass alterations in mortar mixtures subsequent to exposure to elevated temperatures might provide valuable insights on the physical and chemical transformations that transpire inside the mortar mixture. Figure 6 illustrates the mass reduction of a mortar mixture using CBA as a partial substitute for cement after exposure to elevated temperatures (200°C, 400°C, 600°C). The results indicate that there is a positive correlation between the percentage of ground CBA replacement and the rate of mass loss, as well as a rise in temperature. The samples without ground CBA control samples exhibit superior resistivity at all temperatures. At a temperature of 200°C, the magnitude of mass loss exhibited a similar pattern for each combination within the range of 1,5 % to 4,54 %. Nevertheless, the rate of mass loss exhibits a substantial augmentation when subjected to temperatures over 400°C. According to the findings of Wang et al.(45) weight loss mostly occurs owing to the liberation of water while the temperature remains below 400°C. At a temperature of 600°C, the mortar exhibited a greater degree of mass loss in comparison to different temperatures, with values varying from 5,57 % to 8,61 %. The present observation unequivocally demonstrates that the specimens with ground CBA exhibit a much higher rate of mass loss than the control mortar. In their study, Nathe et al.(41) observed that samples containing ground CBA experience a greater reduction in mass compared with control samples when exposed to temperatures ranging from 200°C to 600°C. This phenomenon may be attributed to the breakdown of ground CBA at elevated temperatures, leading to the formation of porosity within the structure. Fig. 6 depicts the ratio of mass loss in each mix ratio as a proportion. The primary cause of mass reduction in concrete is mostly attributed to the loss of moisture. Furthermore, the reduction in mass caused by heating is a consequence of the release of unbound water (located in capillary pores) and chemically bonded water from the cementitious paste. In the present investigation, the presence of free water in mortar mixes is deemed negligible because all samples underwent oven drying to achieve a consistent mass at a temperature of 105°C prior to exposure to increased temperatures of 200°C. Consequently, the observed reduction in mass during the heating process may be ascribed to the evaporation of gel water and the release of chemically bonded water from cement hydrates. Previous studies (46,47) have shown that the decomposition of calcium hydroxide (CH) in concrete mixes occurs when exposed to external temperatures above 400°C. This phenomenon is attributed to the thermal gradient between the outer and inner regions of thick mortar mixtures. Hence, it can be inferred that subjecting the combination to a temperature of 600°C primarily leads to the total breakdown of the binder gel, which consists of calcium silicate and aluminate hydrates, as well as the partial removal of water from the calcium hydroxide present in the mortar mixes. The findings presented in this study are consistent with other research, whereby a reduction in mass loss was seen.(48,49)

Figure 6. Loss weight of specimens’ mortar with CBA as partial after exposure to elevated temperatures

Surface observations

The alterations seen on the concrete surfaces after heat exposure included phenomena such as discoloration surface spalling, and the creation of cracks, as visually shown. The primary objective of this study was to investigate the occurrence of fracture development, as well as the well-documented phenomena of discoloration and surface spalling, which are often seen on concrete surfaces after exposure to elevated temperatures. These phenomena have been thoroughly examined in previous research efforts. The experimental findings indicate that concrete specimens subjected to a temperature of 600°C exhibit a higher occurrence of surface fractures compared to concrete specimens treated to the same temperature for all cylindrical samples, as visually shown in Fig.7. This finding may deviate from traditional opinion, as it may be argued that there is a strong correlation between the rise in exposure temperature and the escalation of thermal damage and the production of cracks in concrete. To yet, no empirical studies have documented any instances of incongruity between the temperature of exposure and the occurrence of fracture development. Furthermore, the findings of this study demonstrate that the inclusion of ground CBA has effectively mitigated fracture damage, as seen in the accompanying figure 7.

Figure 7. Surfaces of elevated temperature exposed specimens at 600°C: (a) discoloration, (b) surface spalling, and (c) crack formation

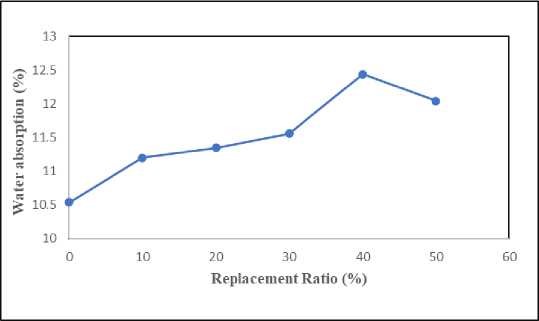

Water absorption

Figure 8 depicts the absorption results associated with mortar samples manufactured using different ground CBA materials as partial substitutes. The water absorption of the mortar is influenced by the amount of CBA used. Water absorption exhibited a positive correlation with the proportional increase in the quantity of CBA particles. The water absorption of mortar samples with varying percentages of CBA as a partial substitute for cement at 28 days was observed to be 10,54 %, 11,215 %, 11,35 %, 11,56 %, 12,44 %, and 12,041 % for 0 %, 10 %, 20 %, 30 %, 40 %, and 50 % CBA content, respectively. The figure demonstrates a regular rise in the total apparent porosity with a rise in the amount of CBA. The noticed rise in volume is believed to be the result of two factors: the porous structure of CBA, as illustrated in Fig. 8, and the cavities that form in the cement matrix due to the evaporation of free water in mortar. A similar trend was detected down to the microscopic level. The relationship between the amount of water absorption in the mortar specimens and the degree of porosity has been observed. The inclusion of ground CBA in mortar resulted in a greater porosity compared to mortar without CBA. Furthermore, when the percentage of ground CBA used as a partial substitute for cement in the mortar mixture increased from 10 % to 50 %, the difference in porosity between the two samples reduced from 2 % to 3 %. The observed variation in mortar porosities may be attributed mostly to the much higher porosity shown by the ground CBA samples compared with the control samples. Nevertheless, when the replacement percentage increases to 20 % and beyond, the mortar exhibits a higher degree of water absorption. The mortar mixture demonstrated an increase in the percentage of water absorption when a greater amount of ground CBA was included into the mixture. The use of a significant amount of ground CBA as a substitute for cement in mortar has been seen to result in the generation of an increased number of voids, thus leading to elevated levels of water absorption. These findings align with the results of prior research, which also reported an increase in water absorption.(50,51,52)

Figure 8. Water absorption results of mortars with various replacement ratios of CBA as partial cement replacement at 28 days

CONCLUSION

In this experimental investigation, the impact of CBA on the mechanical and physical properties of cement compounds exposed to temperatures as high as 600°C is examined. In summary, the principal conclusions are as follows:

· The observed reduction in the mass loss of mortars employing CBA as a partial substitute for cement was found to be significant as the temperature increased, up to a maximum of 600°C. The increase in the pore volume may be attributed to the decreased specific gravity of CBA.

· Based on a visual examination, it may be inferred that there is a marginal alteration in color up to a temperature of 200°C. Cracks begin to manifest in the samples, accompanied by a noticeable change in color, after the temperature surpasses 400°C and reaches around 600°C.

· The incorporation of CBA as a partial substitute for cement in cement mortar yielded favorable results in terms of mechanical properties. At 28 days of age, the compressive strength of all specimens was found to meet the specified value. In addition, it was determined that the optimal replacement ratio for achieving satisfactory strength is up to 20 %.

· This study may be regarded as an ecologically conscious approach that focuses on the use of recycled waste materials in the construction of mortar.

ACKNOWLEDGEMENTS

The authors would like to thank Ministry of Higher Education for providing financial support under fundamental research grant Scheme (FRGS) No. (FRGS/1/2022/TK01/UMP/02/5 (university reference RDU (220112) and Universiti Malaysia Pahang AL-Sultan Abdullah (UMPSA) for laboratory facilities and additional support under internal grant No. RDU 223313, as well as additional financial support under the university of Fallujah.

REFERENCES

1. M. I. Al Biajawi, R. Embong, K. Muthusamy, and N. Mohamad, “Effect of fly ash and coal bottom ash as alternative materials in the production of self compacting concrete: A review,” in AIP Conference Proceedings, 2023, vol. 2688, no. 1.

2. A. Kusbiantoro, R. Embong, and A. Abd Aziz, “Strength and Microstructural Properties of Mortar Containing Soluble Silica from Sugarcane Bagasse Ash,” in Key Engineering Materials, 2018, vol. 765, pp. 269–274.

3. A. Kusbiantoro, R. Embong, and N. Shafiq, “Adaptation of eco-friendly approach in the production of soluble pozzolanic material,” International Journal of Design & Nature and Ecodynamics, vol. 12, no. 2, pp. 246–253, 2017.

4. W. Al-Rifaie, A. Alawaneh, M. Al-Bajawi, and W. Ahmed, “Effect of Nano Silica on Compressive Strength of Concrete,” in ASME International Mechanical Engineering Congress and Exposition, 2018, vol. 52170, p. V012T11A044.

5. M. I. Y. Al Biajawi and R. Embong, “The Impact of Varying Ratios of Water-to-Cement Content on the Fresh and Strength Properties of Self-Compacting Concrete,” Construction Technologies and Architecture, vol. 4, pp. 69–80, 2023.

6. V. Kodur, “Properties of concrete at elevated temperatures,” International Scholarly Research Notices, vol. 2014, 2014.

7. D. A. Krishna, R. S. Priyadarsini, and S. Narayanan, “Effect of elevated temperatures on the mechanical properties of concrete,” Procedia Structural Integrity, vol. 14, pp. 384–394, 2019.

8. M. Malik, S. K. Bhattacharyya, and S. V Barai, “Thermal and mechanical properties of concrete and its constituents at elevated temperatures: A review,” Construction and Building Materials, vol. 270, p. 121398, 2021.

9. J. Shen and Q. Xu, “Effect of elevated temperatures on compressive strength of concrete,” Construction and Building Materials, vol. 229, p. 116846, 2019.

10. S. R. Abid, A. A. Abbass, G. Murali, M. L. J. Al-Sarray, I. A. Nader, and S. H. Ali, “Repeated impact response of normal-and high-strength concrete subjected to temperatures up to 600 C,” Materials, vol. 15, no. 15, p. 5283, 2022.

11. N. Ghazali et al., “Effect of Fly Ash as Partial Cement Replacement on Workability and Compressive Strength of Palm Oil Clinker Lightweight Concrete,” in IOP Conference Series: Earth and Environmental Science, 2021, vol. 682, no. 1, p. 12038.

12. R. Embong, A. Kusbiantoro, A. Abd Wahab, and K. Muthusamy, “Soluble Pozzolanic Materials from Coal Bottom Ash as Cement Replacement Material,” in Key Engineering Materials, 2021, vol. 879, pp. 68–80.

13. É. Lublóy, K. Kopecskó, G. L. Balázs, Á. Restás, and I. M. Szilágyi, “Improved fire resistance by using Portland-pozzolana or Portland-fly ash cements,” Journal of Thermal Analysis and Calorimetry, vol. 129, pp. 925–936, 2017.

14. A. O. Habib, I. Aiad, F. I. El-Hosiny, and A. M. Abd El-Aziz, “Development of the fire resistance and mechanical characteristics of silica fume-blended cement pastes using some chemical admixtures,” Construction and Building Materials, vol. 181, pp. 163–174, 2018.

15. V. M. Malhotra and P. K. Mehta, Pozzolanic and Cementitious Materials. CRC Press, 1996. doi: 10.1201/9781482296761.

16. M. I. Al Biajawi, R. Embong, A. Kusbiantoro, H. Abdel-Jabbar, and A. H. Azmi, “Impact of recycled coal bottom ash as mixing ingredient on fresh and mechanical properties of concrete: A review,” Materials Today: Proceedings, 2023.

17. M. I. Al Biajawi, R. Embong, and A. Shubbar, “Engineering properties of self-compacting concrete incorporating coal bottom ash (CBA) as sustainable materials for green concrete: a review,” Journal of Building Pathology and Rehabilitation, vol. 8, no. 2, p. 105, 2023.

18. M. A. Moghadam and R. A. Izadifard, “Effects of zeolite and silica fume substitution on the microstructure and mechanical properties of mortar at high temperatures,” Construction and Building Materials, vol. 253, p. 119206, 2020.

19. M. J. Miah, M. K. Ali, F. Lo Monte, S. C. Paul, A. J. Babafemi, and B. Šavija, “The effect of furnace steel slag powder on the performance of cementitious mortar at ambient temperature and after exposure to elevated temperatures,” in Structures, 2021, vol. 33, pp. 2811–2823.

20. M. Abed, R. Nemes, and É. Lublóy, “Performance of self-compacting high-performance concrete produced with waste materials after exposure to elevated temperature,” Journal of Materials in Civil Engineering, vol. 32, no. 1, p. 5019004, 2020.

21. S. Prakash, S. Kumar, R. Biswas, and B. Rai, “Influence of silica fume and ground granulated blast furnace slag on the engineering properties of ultra-high-performance concrete,” Innovative Infrastructure Solutions, vol. 7, pp. 1–18, 2022.

22. M. F. Ghazy, M. A. A. Elaty, and R. S. Elkhoriby, “Performance of blended cement mortars incorporating nano-metakaolin particles at elevated temperatures,” in Proceeding of the International Conference on Advances in Structural and Geotechnical Engineering, Hurghada, Egypt, 2015, pp. 6–9.

23. O. Arioz, “Effects of elevated temperatures on properties of concrete,” Fire safety journal, vol. 42, no. 8, pp. 516–522, 2007.

24. M. S. Morsy, A. M. Rashad, and S. S. Shebl, “Effect of elevated temperature on compressive strength of blended cement mortar,” Build Res J, vol. 56, no. 2–3, pp. 173–185, 2008.

25. A. O. Tanash, B. H. A. Bakar, K. Muthusamy, and M. I. A. L. Biajawi, “Effect of elevated temperature on mechanical properties of normal strength concrete: An overview,” Materials Today: Proceedings, 2023.

26. E. D. Shumuye, J. Zhao, and Z. Wang, “Effect of fire exposure on physico-mechanical and microstructural properties of concrete containing high volume slag cement,” Construction and Building Materials, vol. 213, pp. 447–458, 2019.

27. K. Tamanna, S. N. Raman, M. Jamil, and R. Hamid, “Coal bottom ash as supplementary material for sustainable construction: A comprehensive review,” Construction and Building Materials, vol. 389, p. 131679, 2023.

28. R. Embong and A. Kusbiantoro, “Study on the early hydration of cement paste containing sodium chloride,” in Applied Mechanics and Materials, 2014, vol. 621, pp. 35–38.

29. M. I. Al Biajawi and R. Embong, “Influence of setting time and compressive strength for coal bottom ash as partial cement replacement in mortar,” Maejo International Journal of Energy and Environmental Communication, vol. 5, no. 3, pp. 1–5, 2023.

30. A. U. Abubakar, K. S. Baharudin, and I. Technology, “Potential Use of Malaysian Thermal Power Plants,” vol. 3, no. 2, pp. 25–37, 2012.

31. J. Y. Park, “Assessing determinants of industrial waste reuse: The case of coal ash in the United States,” Resources, Conservation and Recycling, vol. 92, pp. 116–127, 2014.

32. K. Kiattikomol, C. Jaturapitakkul, S. Songpiriyakij, and S. Chutubtim, “A study of ground coarse fly ashes with different finenesses from various sources as pozzolanic materials,” Cement and Concrete Composites, vol. 23, no. 4–5, pp. 335–343, Aug. 2001, doi: 10.1016/S0958-9465(01)00016-6.

33. P. Chindaprasirt, S. Homwuttiwong, and V. Sirivivatnanon, “Influence of fly ash fineness on strength, drying shrinkage and sulfate resistance of blended cement mortar,” Cement and Concrete Research, vol. 34, no. 7, pp. 1087–1092, Jul. 2004, doi: 10.1016/j.cemconres.2003.11.021.

34. B. Felekoğlu, S. Türkel, and H. Kalyoncu, “Optimization of fineness to maximize the strength activity of high-calcium ground fly ash – Portland cement composites,” Construction and Building Materials, vol. 23, no. 5, pp. 2053–2061, May 2009, doi: 10.1016/j.conbuildmat.2008.08.024.

35. S. A. Mangi, M. H. Wan Ibrahim, N. Jamaluddin, M. F. Arshad, S. A. Memon, and S. Shahidan, “Effects of grinding process on the properties of the coal bottom ash and cement paste,” Journal of Engineering and Technological Sciences, vol. 51, no. 1, pp. 1–13, Feb. 2019, doi: 10.5614/j.eng.technol.sci.2019.51.1.1.

36. S. A. Mangi, M. H. Wan Ibrahim, N. Jamaluddin, M. F. Arshad, and P. J. Ramadhansyah, “Effects of ground coal bottom ash on the properties of concrete,” Journal of Engineering Science and Technology, vol. 14, no. 1, pp. 338–350, 2019.

37. A. Standard, “ASTM C778-13,” Standard Specification for Standard Sand. ASTM International, 2013.

38. ASTM C618, “ASTM C618-19, Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete,” Annual Book of ASTM Standards, no. C, p. 5, 2019, doi: 10.1520/C0618-19.

39. A. Standard, “C109/C109M-16a,” Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (using 2-in. Or [50-mm] Cube Specimens),”,” Committee C-1 on Cement, ed. West Conshohocken, PA, USA: ASTM International, 2013.

40. A. ASTM C642, “Standard test method for density, absorption, and voids in hardened concrete,” ASTM, ASTM International, 2013.

41. D. N. Nathe and Y. D. Patil, “Performance of coal bottom ash concrete at elevated temperatures,” Materials Today: Proceedings, vol. 65, pp. 883–888, 2022.

42. Y. B. Ahn, J. G. Jang, and H. K. Lee, “Mechanical properties of lightweight concrete made with coal ashes after exposure to elevated temperatures,” Cement and Concrete Composites, vol. 72, pp. 27–38, Sep. 2016, doi: 10.1016/j.cemconcomp.2016.05.028.

43. Q. Ma, R. Guo, Z. Zhao, Z. Lin, and K. He, “Mechanical properties of concrete at high temperature—A review,” Construction and Building Materials, vol. 93, pp. 371–383, 2015.

44. A. Savva, P. Manita, and K. K. Sideris, “Influence of elevated temperatures on the mechanical properties of blended cement concretes prepared with limestone and siliceous aggregates,” Cement and Concrete Composites, vol. 27, no. 2, pp. 239–248, 2005.

45. Y. Wang, F. Liu, L. Xu, and H. Zhao, “Effect of elevated temperatures and cooling methods on strength of concrete made with coarse and fine recycled concrete aggregates,” Construction and Building Materials, vol. 210, pp. 540–547, 2019.

46. A. Nadeem, S. A. Memon, and T. Y. Lo, “The performance of fly ash and metakaolin concrete at elevated temperatures,” Construction and Building Materials, vol. 62, pp. 67–76, 2014.

47. M. A. O. Mydin and Y. C. Wang, “Mechanical properties of foamed concrete exposed to high temperatures,” Construction and Building Materials, vol. 26, no. 1, pp. 638–654, 2012.

48. S. Maheswaran, N. R. Iyer, G. S. Palani, R. A. Pandi, D. D. Dikar, and S. Kalaiselvam, “Effect of high temperature on the properties of ternary blended cement pastes and mortars,” Journal of Thermal Analysis and Calorimetry, vol. 122, pp. 775–786, 2015.

49. F. Althoey, A. K. A. El-Aal, H. Shoukry, and I. Hakeem, “Performance of cement mortars containing clay exposed to high temperature,” Arabian Journal for Science and Engineering, pp. 1–9, 2021.

50. S. S. Jambri and N. Ali, “Performance of Coal Bottom Ash as Partial Cement Replacement in Mortar,” Recent Trends in Civil Engineering and Built Environment, vol. 4, no. 2, pp. 189–196, 2023.

51. F. Saleh et al., “Properties of mortar made with bottom ash and silica fume as sustainable construction materials,” World Journal of Engineering, vol. 20, no. 5, pp. 835–845, 2023.

52. R. C. Amat et al., “Effect of Incorporating Coal Bottom Ash on The Properties of Concrete,” in IOP Conference Series: Earth and Environmental Science, 2023, vol. 1216, no. 1, p. 12024.

FINANCING

The authors did not receive funding for the development of this research.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

AUTHORSHIP CONTRIBUTION

Conceptualization: Mohammad I. Al Biajawi, Rahimah Embong, Khairunisa Muthusamy, Haneen Abdel Jabar, Nahla Hilal, Fadzli Mohamed Nazri.

Formal analysis: Mohammad I. Al Biajawi, Rahimah Embong, Khairunisa Muthusamy, Haneen Abdel Jabar, Nahla Hilal, Fadzli Mohamed Nazri.

Research: Mohammad I. Al Biajawi, Rahimah Embong, Khairunisa Muthusamy, Haneen Abdel Jabar, Nahla Hilal, Fadzli Mohamed Nazri.

Writing - original draft: Mohammad I. Al Biajawi, Rahimah Embong, Khairunisa Muthusamy, Haneen Abdel Jabar, Nahla Hilal, Fadzli Mohamed Nazri.

Writing - revision and editing: Mohammad I. Al Biajawi, Rahimah Embong, Khairunisa Muthusamy, Haneen Abdel Jabar, Nahla Hilal, Fadzli Mohamed Nazri.